Genset Monitoring

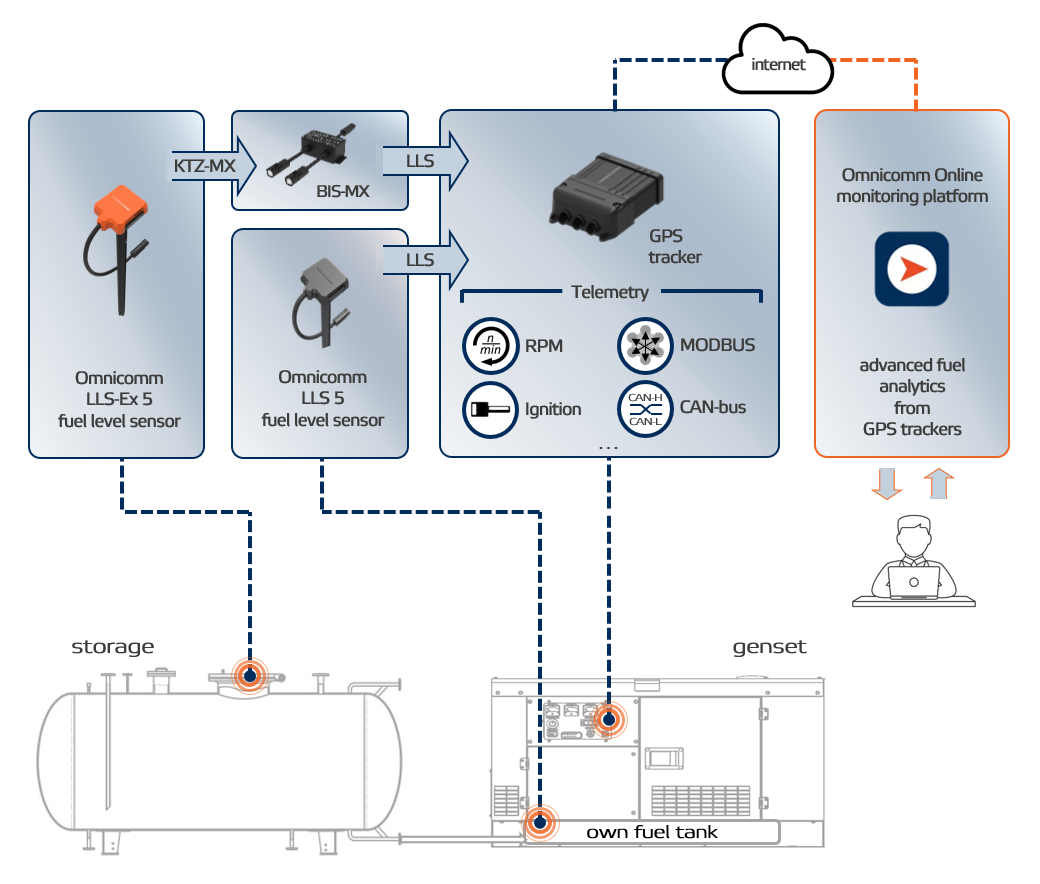

Omnicomm’s fuel level monitoring system ensures reliable and efficient operation of generators by providing real-time data on fuel consumption in both internal tanks and external storage facilities. This solution helps prevent unexpected downtime, optimize refueling schedules, and detect potential leaks or theft, ensuring uninterrupted power supply and cost savings.

In different industries and usage scenarios, the set of important parameters to be monitored may vary, e.g.:

| Area | Fuel monitoring | Movement & GPS monitoring | Genset utilization & overloads | CAN-bus readings | Auxiliary equipment | Geofences & routes | CO2 emissions (standstills) | Remote disabling | RFID/iButton (authorization) |

|---|---|---|---|---|---|---|---|---|---|

| Data centers | + | + | + | + | |||||

| Telecom | + | + | + | + | |||||

| Fuel stations | + | + | + | ||||||

| Banks | + | + | + | + | |||||

| Hospitals | + | + | + | + | + | ||||

| Construction | + | + | + | + | + | + | |||

| Leasing | + | + | + | + | + | + | + |

With remote monitoring and automated reporting, Omnicomm’s system offers full visibility into fuel levels and reduces risks associated with fuel shortages or irregularities.

In addition to fuel monitoring, many parameters from auxiliary sensors can be monitored, including via CAN-bus or MODBUS interfaces. This is especially useful when data on power output, current, voltage, etc. is available, both phase-by-phase and total.

| OMNICOMM LLS 5 fuel level sensors are exceptionally robust, extremely precise (99.5% accuracy), totally reliable (highest possible ingress protection rating of IP69k) and super-safe. They deliver consistently high accuracy in even the harshest conditions. This sensor is ideal for both vehicles and stationary fuel storage facilities, guaranteeing seamless operation and maximum economic efficiency. OMNICOMM LLS 5 using unique fuel analysis technology FUELSCAN® developed by OMNICOMM which compares the physical characteristics of filled fuel with the characteristics of the fuel used for calibration to introduce a correction coefficient that automatically adjusts sensor readings to deliver accurate measurements. It means that no additional calibrations will be required. See more details in the user manual: link |

|

| OMNICOMM LLS-Ex 5 is the explosion-proof variant of the OMNICOMM LLS 5, designed for use in large tanks and facilities with stringent safety requirements — such as fuel storage depots, gas stations, and bowsers. This device must always be operated in conjunction with the BIS-MX power protection unit, installed in a safe zone. Certified by ATEX, the LLS-Ex 5 is approved for use in hazardous environments where flammable substances pose an explosion risk. Its robust design ensures compliance with safety standards across multiple industries, safeguarding both personnel and infrastructure. See more details in the user manual: link |

|

| BIS-MX intrinsic safety unit is designed to protect circuits when exposed to a voltage of up to 250 V. LLS-Ex 5 fuel level sensor is located in a hazardous area, and BIS-MX should be located in the explosion safe area. See more details in the user manual: link |

|

| KTZ-MX is the extension cable, with options 15 and 20 meters, to connect LLS-Ex 5 (located in hazardous area) to BIS-MX (located in the safe zone) | |

| OMNICOMM Profi Wi-Fi is an IP54 rating GPS-tracker that ensures stable data transmission in remote and challenging locations without cellular coverage. By using Wi-Fi for data transfer, the tracker enables effective monitoring even in areas where traditional communication methods fail. This solution is ideal for agricultural, construction, and mining industries, ensuring continuous tracking and reliable operation in the absence of cellular networks. The OMNICOMM Profi Wi-Fi tracker enhances fleet control in the most challenging environments. Combined with the OMNICOMM Online platform, it provides reliable connectivity and accuracy, improving fleet management and reducing the risk of losing control over assets. See more details in the user manual: link |

|

| OMNICOMM Online is a cloud platform that provides users with the best fuel analytics tools and operational insights into monitored facilities. The platform delivers a complete picture of fuel costs and fuel consumption across vehicles. See more details in the user manual: link |

|

| OMNICOMM ICON is a modern multifunctional display designed to show key vehicle performance parameters in real time. ICON provides drivers with timely and clear information, improving control over fuel consumption, speed, engine operating modes, and other critical indicators. The display integrates with the vehicle monitoring system, optimizing equipment use and enhancing safety. ICON is used together with OMNICOMM GPS trackers and/or up to 4 LLS digital fuel level sensors and reads the data through the RS-485 digital interface. ICON helps transport and logistics companies monitor vehicle operation, reduce fuel costs, and prevent emergencies. See more details in the user manual: link |

|

An example of a list of reports that would be helpful in a given case is provided below:

| Category | Reports |

|---|---|

| Fuel | Fuel Volume, Refueling and Draining, Fuel Balance, MultiTank |

| Cartographic | Location |

| Movement | - |

| Statistics | Statistics, Summary Report |

| Operation | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period |

| Events and Violations | - |

| Analytical | Executive’s Desktop |

| Other | Current State, Visiting the Geofences, Log, Custom Events |

An example specification for a diesel generator with its own tank and external storage, as well as a CAN-bus reading option and ICON display is shown in the table below:

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 - 700mm | 1 |

| Fuel Level Sensor LLS-Ex 5 - 2000mm | 1 |

| BIS-MX spark protection unit | 1 |

| Extension cable KTZ-MX 20 | 1 |

| GPS-tracker Profi Wi-Fi 3.0 / Optim 3.0 / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) | 1 |