Preparation

Fuel Tank Preparation

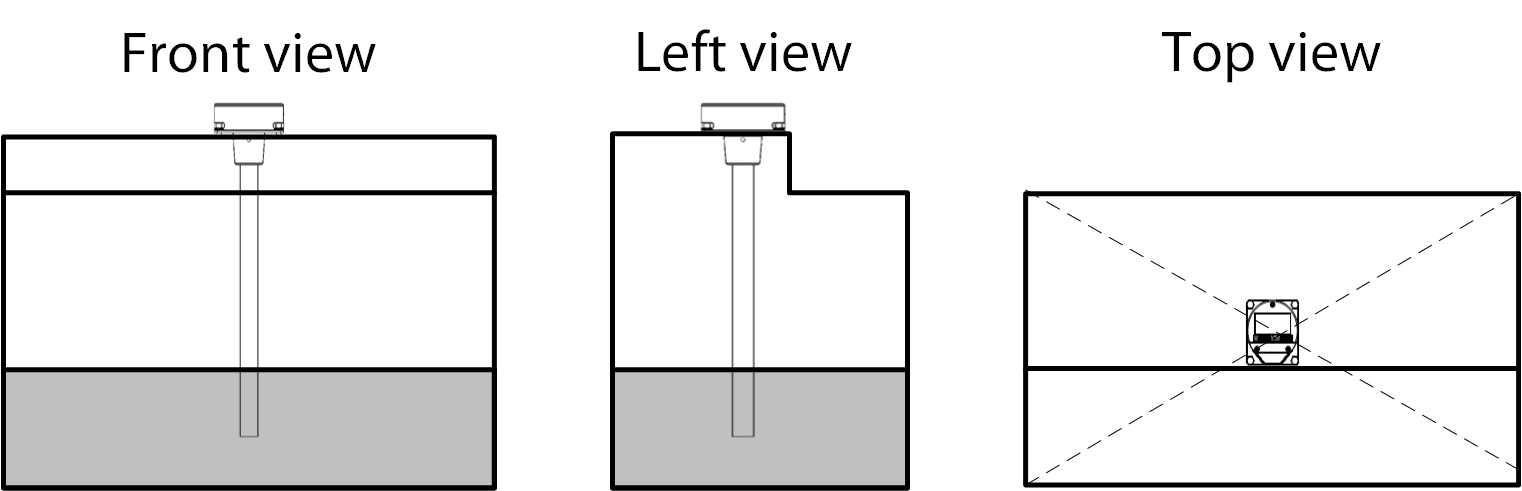

1. Select the location for Omnicomm LLS 4 sensor installation subject to the following requirements:

- Installation location should be as close as possible to the geometric center and placed at the deepest level of the tank:

- When installed, the sensor should not be in contact with reinforcement ribs inside the tank

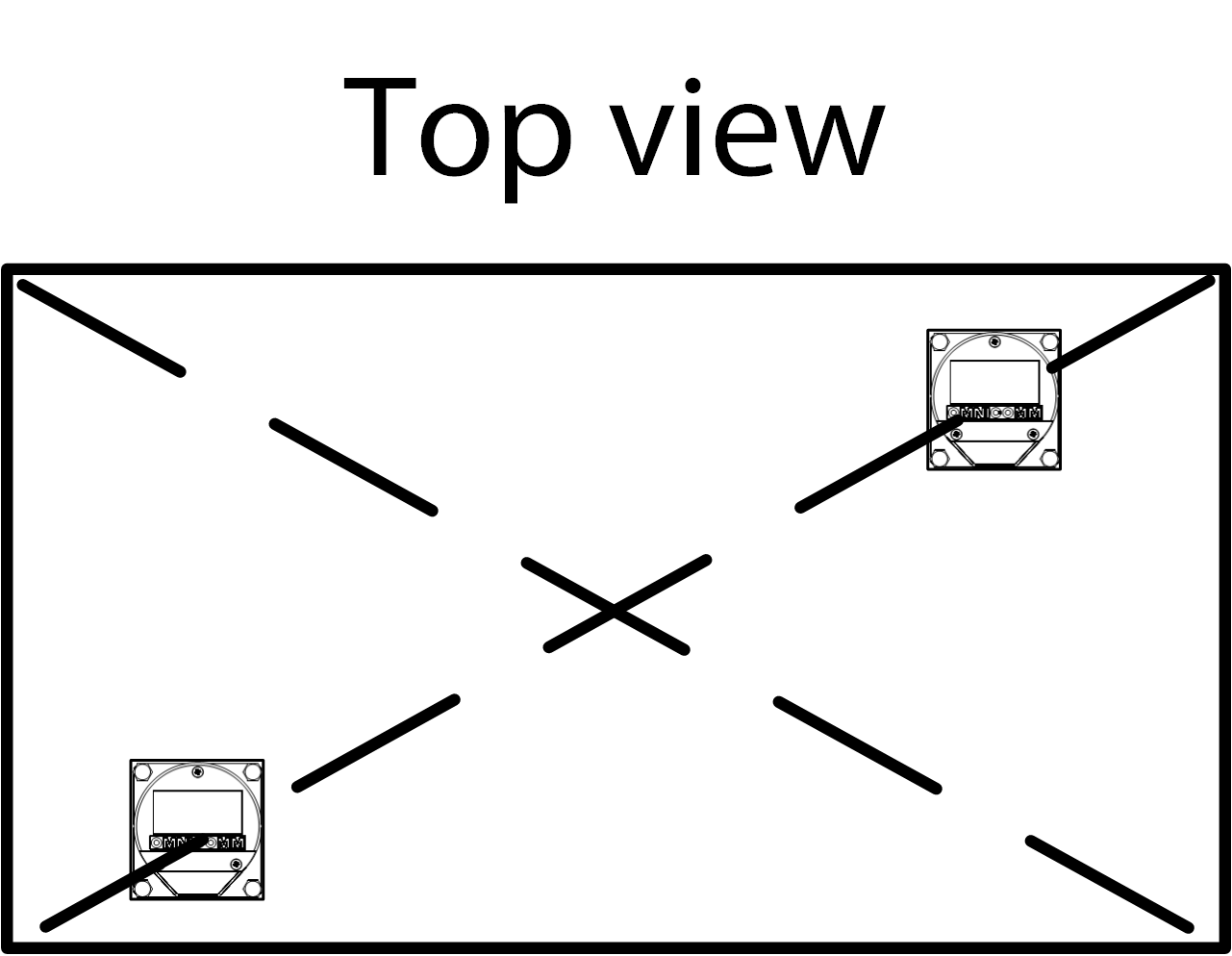

- Installation of two sensors in one tank allows for significant reduction of the fuel level dependence on the vehicle inclination angle:

2. Steam out the tank to ensure compliance with the safety rules

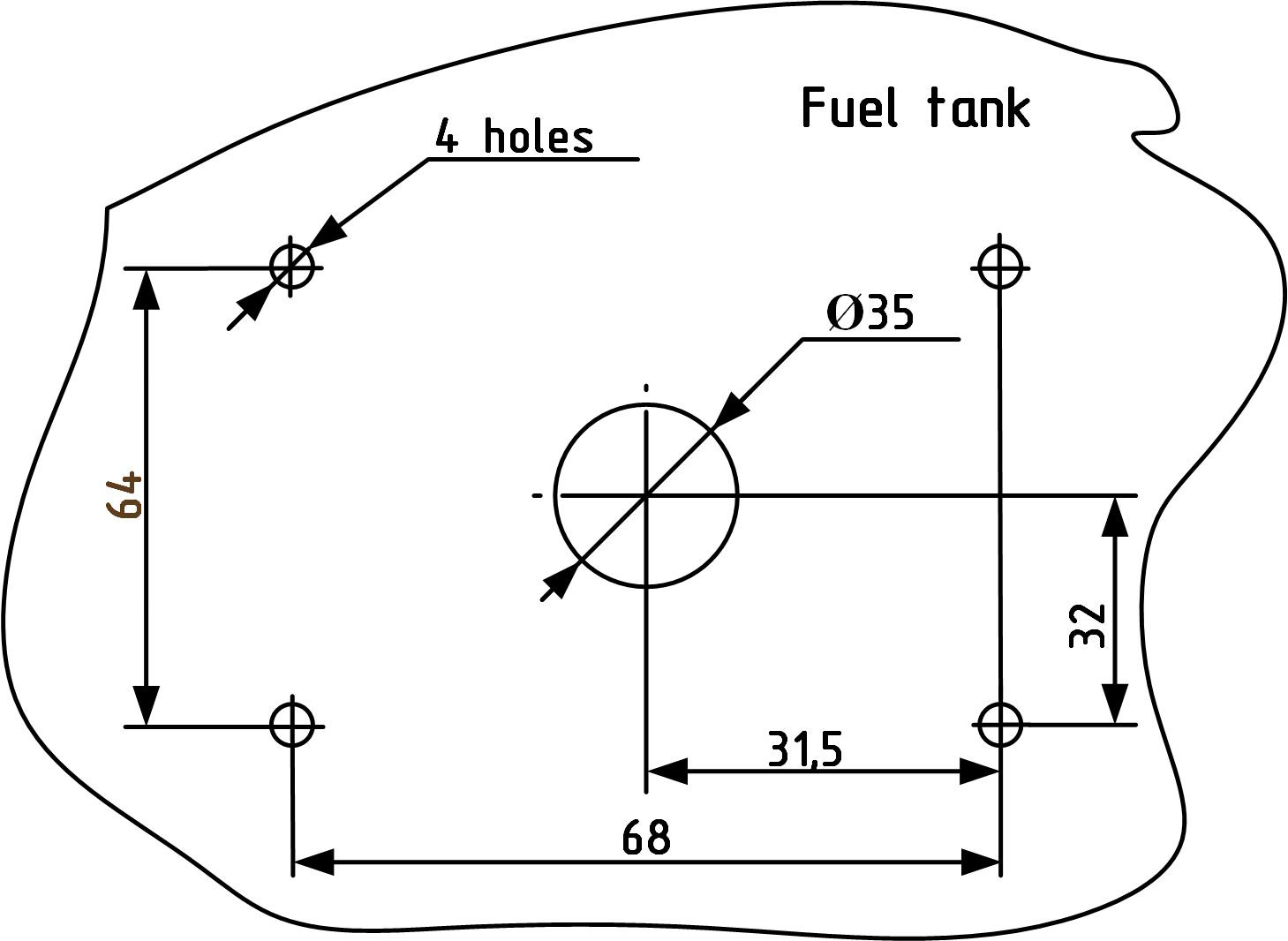

3. Drill out the central bore by bimetal core drill ø35 mm

4. Drill out four mounting holes according to the diagram:

The mounting hole diameter depends on the tank material:

- ø 4 mm – for metal tank with wall thickness over 3 mm (cut M5 thread)

- ø 7 mm – for plastic and metal tank with wall thickness up to 3 mm (for rivets)

- ø 4 mm – for plastic tank with wall thickness over 3 mm

Sensor Preparation

- Measure the tank depth. Cut the sensor measuring piece so that its length is 20 mm less than the depth of the tank. Ensure that shearing line is perpendicular to the sensor longitudinal axis

- Use oil-and-petrol resistant non-conductive sealant to fill the vendor furnished insulation cap up to 1/4–1/5 of its volume. Recommended sealants: PERMATEX™ MotoSeal® Black, ABRO™ Black, ABRO™ Red

- Put the insulation cap on the Omnicomm LLS 4 sensor central rod