GPS Trackers Configuration

Omnicomm Profi 3.0

For additional information refer to User manual.

Omnicomm Optim 3.0

For additional information refer to User manual.

Omnicomm Profi Wi-Fi 3.0

For additional information refer to User manual.

Teltonika FMC125

Step 1: Install Software

1. Download & install Teltonika Configurator for your OS:

2. Install COM Port Drivers for PC communication:

Mounting

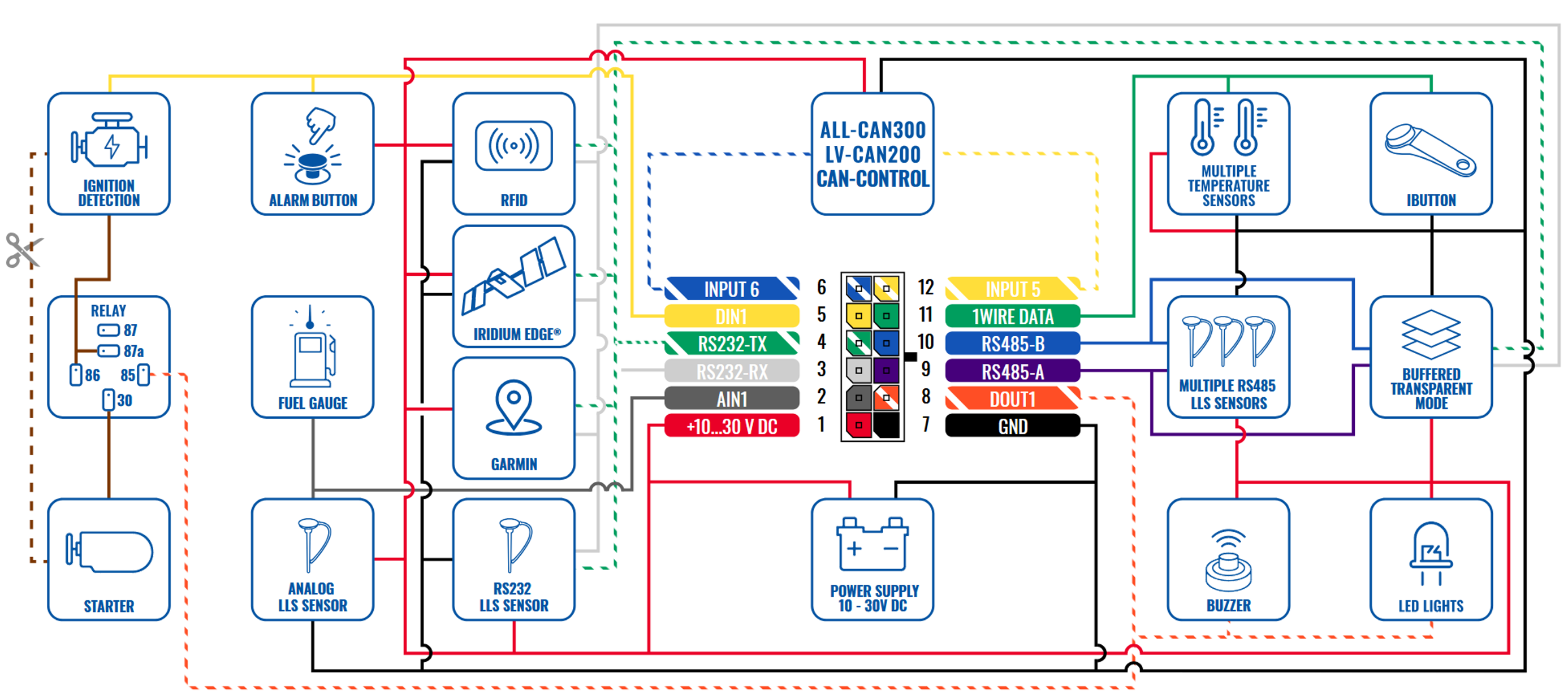

Step 2: Fuel Sensor Connection

FMC 125 MOUNTING RECOMMENDATIONS

CONNECTING WIRES

- Wires should be fastened to the other wires or non-moving parts. Try to avoid heat emitting and moving objects near the wires.

- The connections should not be seen very clearly. If factory isolation was removed while connecting wires, it should be applied again.

- If the wires are placed in the exterior or in places where they can be damaged or exposed to heat, humidity, dirt, etc., additional isolation should be applied.

- Wires cannot be connected to the board computers or control units.

CONNECTING POWER SOURCE

- Be sure that after the car computer falls asleep, power is still available on chosen wire. Depending on car, this may happen in 5 to 30 minutes period.

- When module is connected, measure voltage again to make sure it did not decrease.

- It is recommended to connect to the main power cable in the fuse box.

- Use 3A, 125V external fuse.

CONNECTING IGNITION WIRE

- Be sure to check if it is a real ignition wire i. e. power does not disappear after starting the engine.

- Check if this is not an ACC wire (when key is in the first position, most of the vehicle electronics are available).

- Check if power is still available when you turn off any of vehicles devices.

- Ignition is connected to the ignition relay output. As alternative, any other relay, which has power output when ignition is on, may be chosen.

CONNECTING GROUND WIRE

- Ground wire is connected to the vehicle frame or metal parts that are fixed to the frame.

- If the wire is fixed with the bolt, the loop must be connected to the end of the wire.

- For better contact scrub paint from the spot where loop is going to be connected.

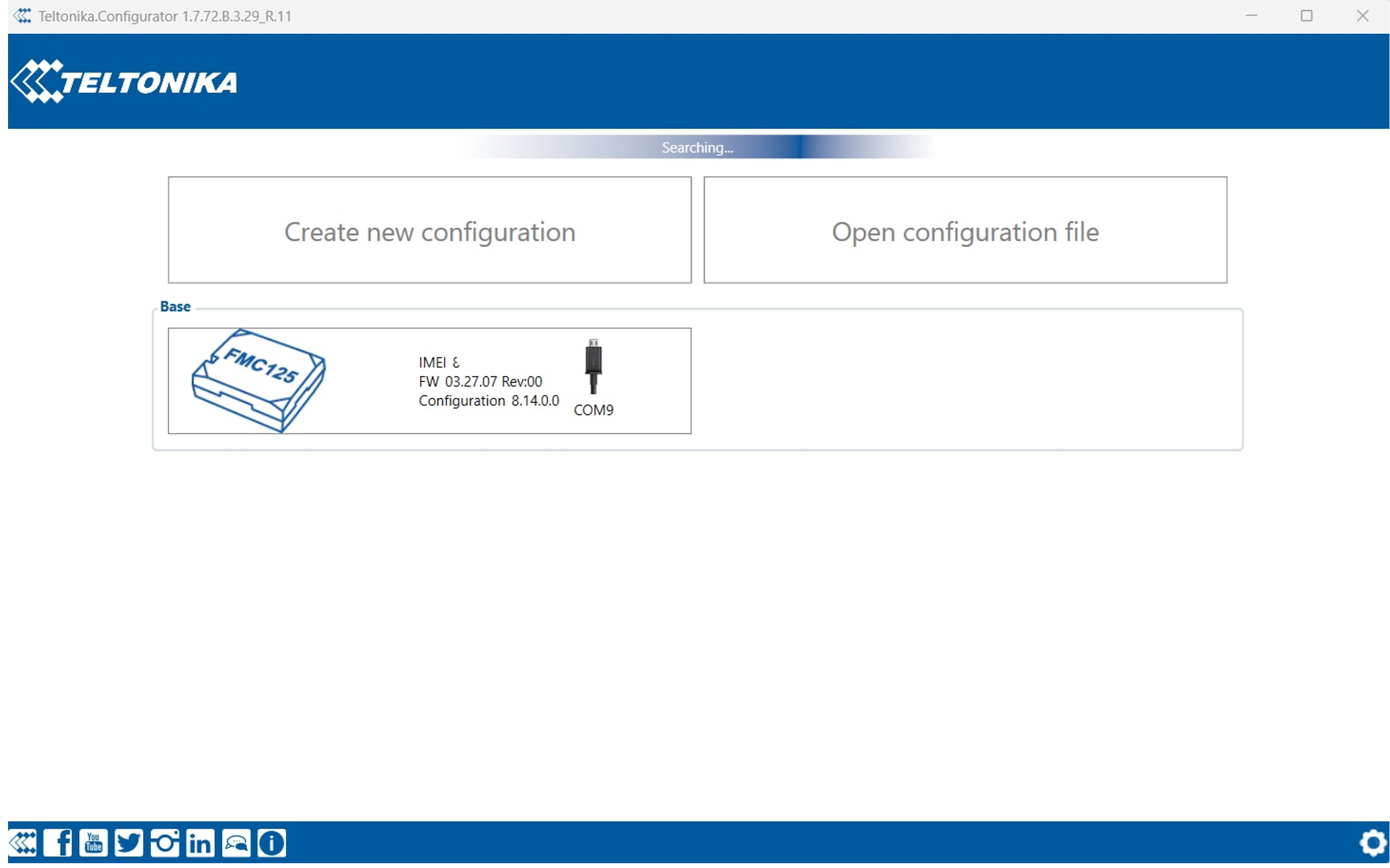

Step 3: Connect FMC125 Tracker

3. Use the micro USB-USB cable or another suitable cable to connect the FMC125 tracker to your PC.*

4. Open Teltonika Configurator and wait for it to detect the connected device(1- 2 min). The configurator could restart after the recognition tracker.

Configuration

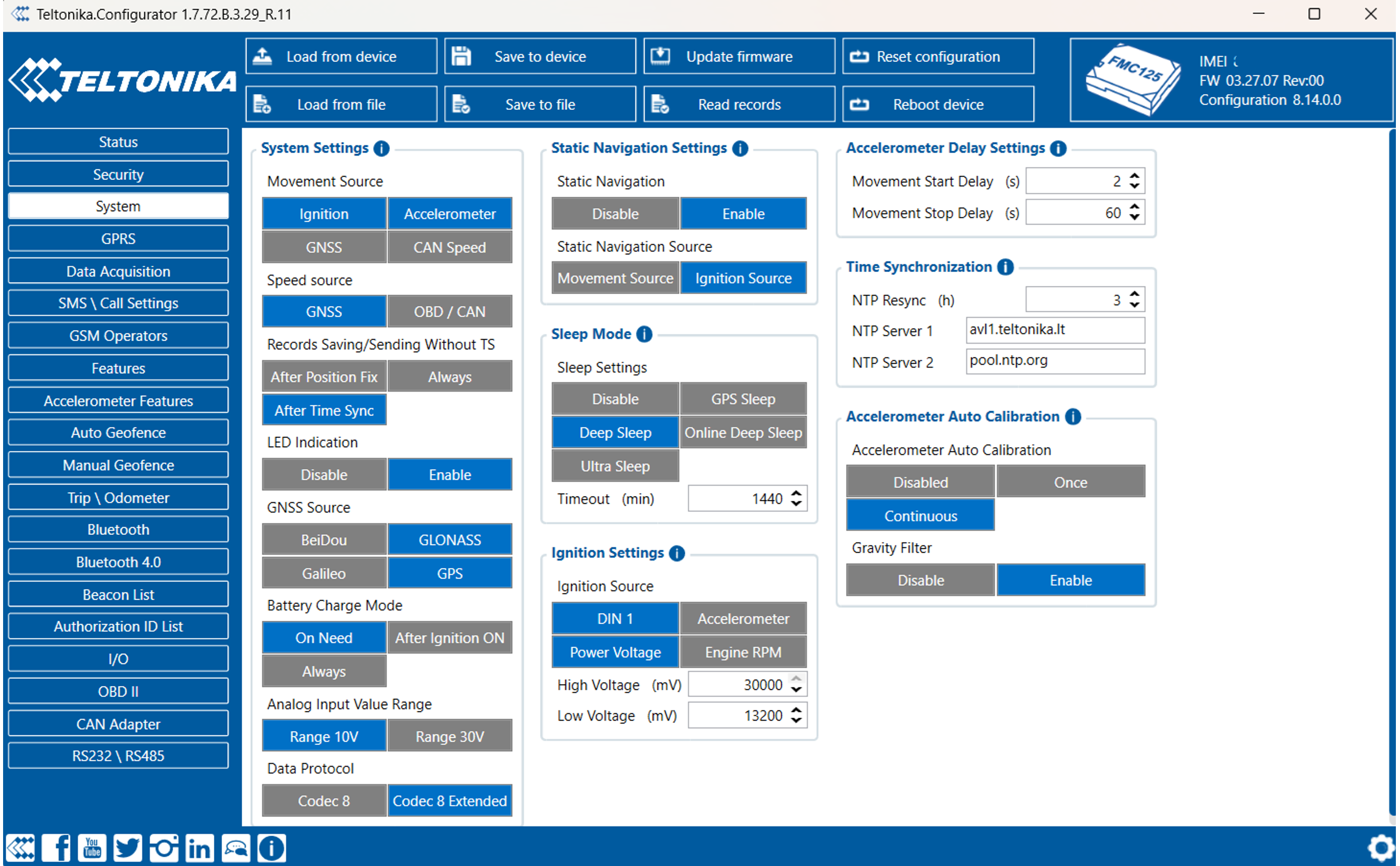

Step 4: Network Configuration

5. When your device appears, enter the configuration window.

6. Go to the System tab.

Set ignition input:

- The ignition wire must be connected to AIN1 input.

- Under Ignition Source, select the corresponding AIN1 flag.

Under Data Protocol, select one of the following:

- Recommended: Codec 8 or Codec 8 Extended

- Note: Choosing a protocol defines which port you'll configure in the GPRS tab.

Under Records Settings set Sort by: Oldest

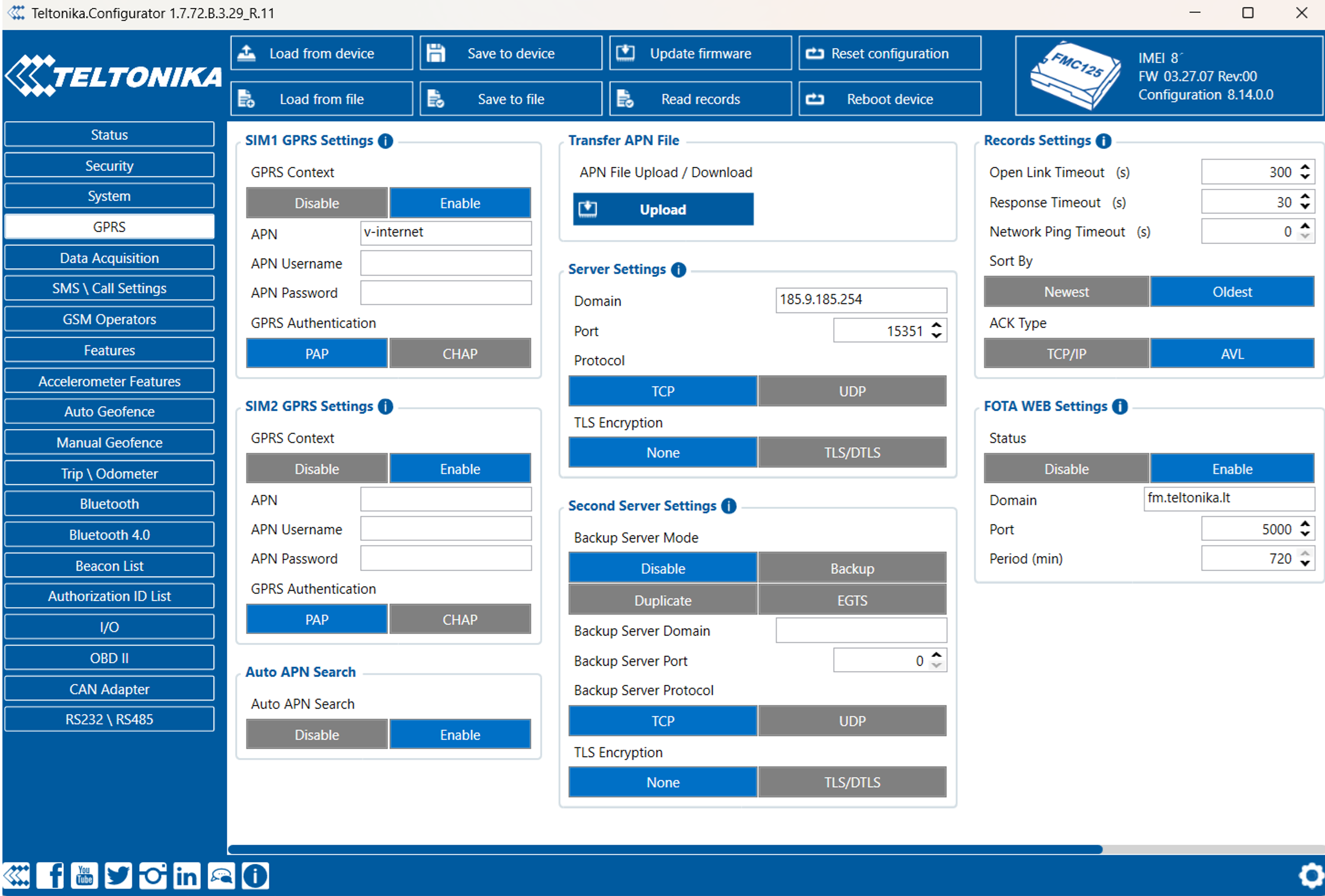

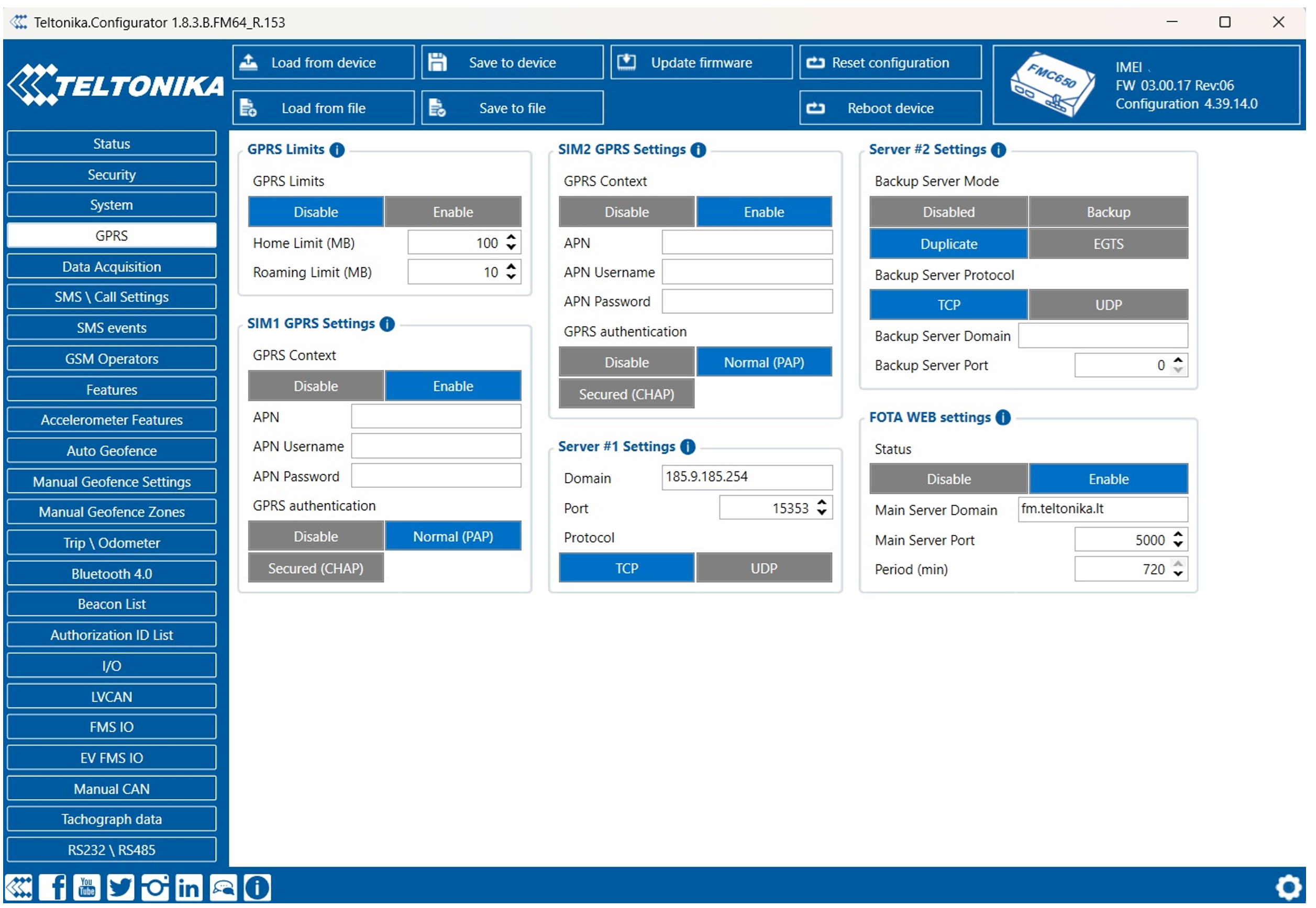

10. Go to the GPRS tab.

Configure APN and password if required by your SIM card provider.

Under Server Settings, enter:

- Domain: 185.9.185.254 or convert.omnicomm.ru

- Port:

Codec 8: 15350 Codec 8 Extended: 15351 Codec 8 Professional: 15352 Codec 8 Professional Extended: 15353

13. Protocol: TCP.

14. Under Records Settings

- Set Sort by: Oldest

Step 4: LLS sensors Settings

RS485:

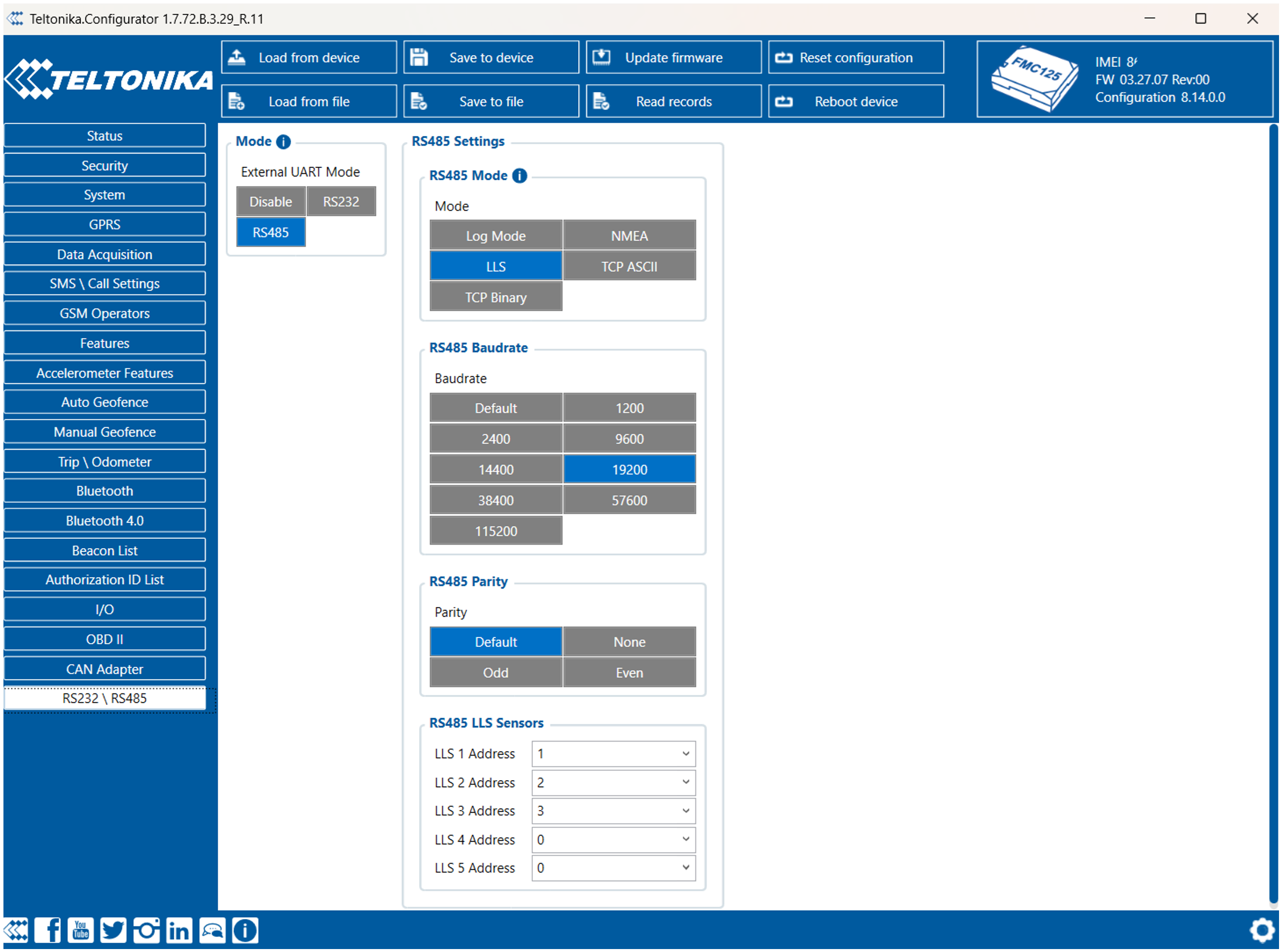

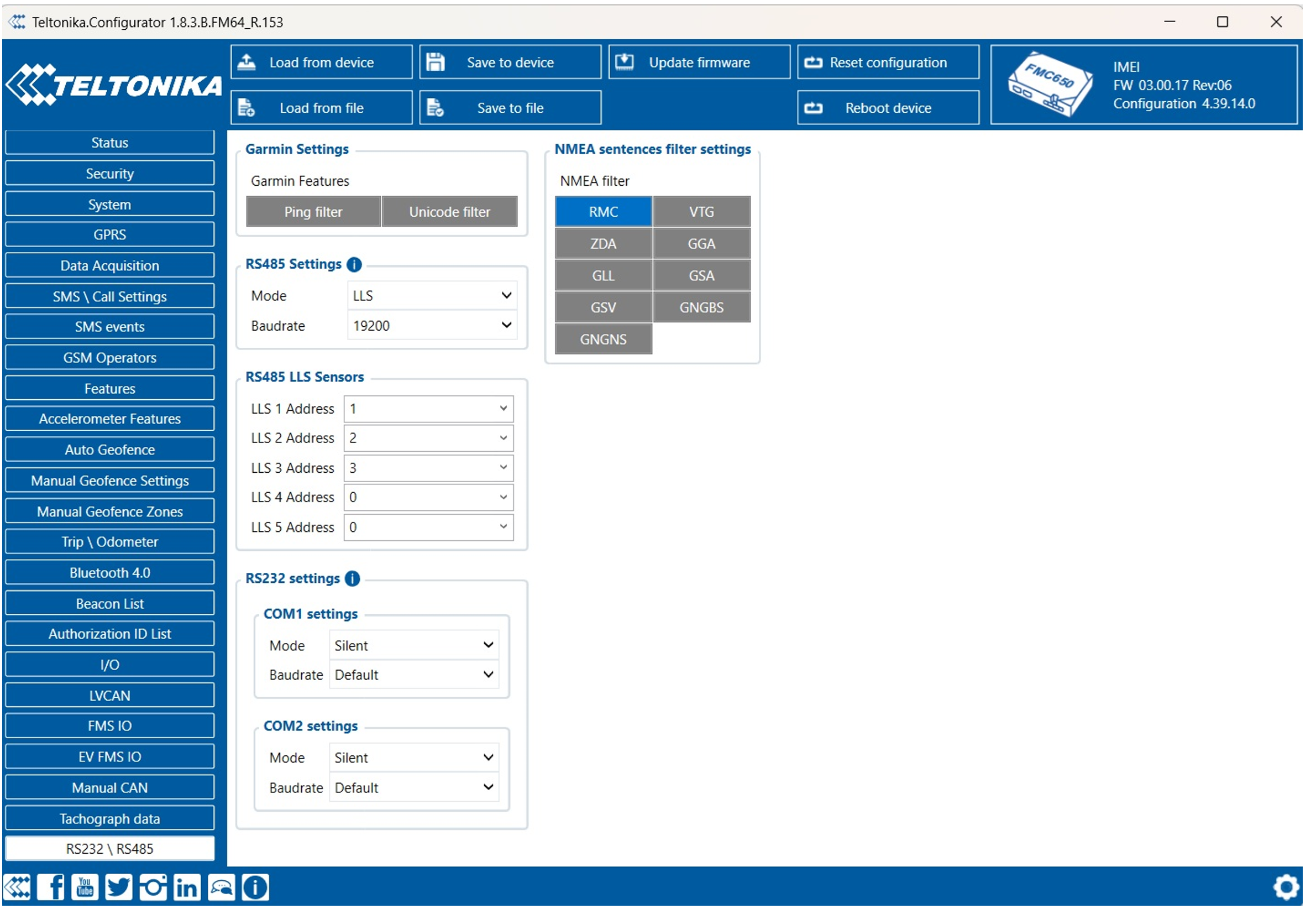

16. Open the RS232/RS485 tab.

17. Under RS485 Settings:

- RS485 Mode: LLS

- Baudrate: 19200 (must match sensor setting)

18. Under RS485 LLS Sensors:

- Set LLS 1 Address: 1

- Set LLS 2 Address: 2, etc.*

- (Sensor IDs must match the ones configured on the LLS sensors.)

*FMC125 supports connection up to 5 digital sensors through RS-485

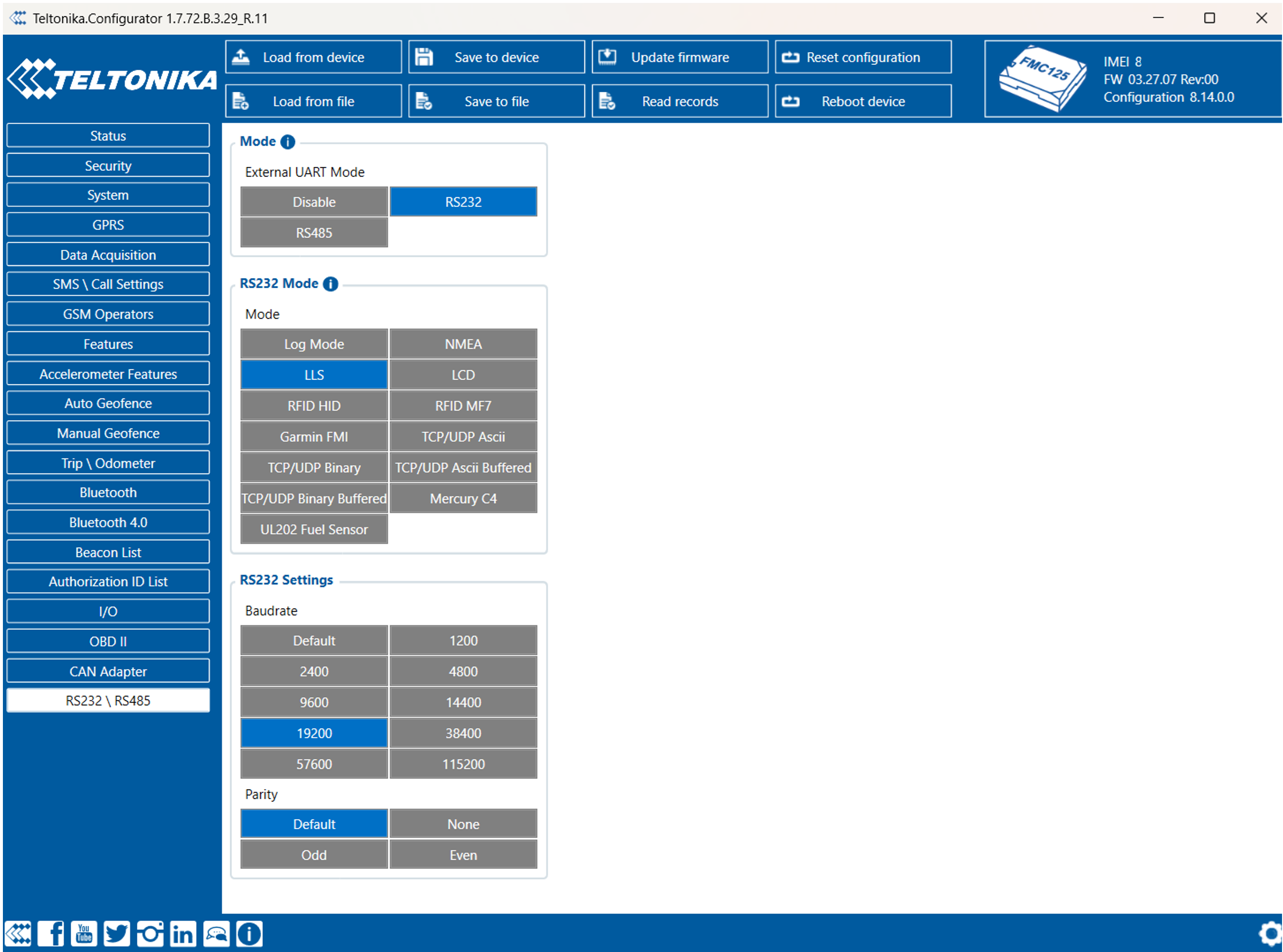

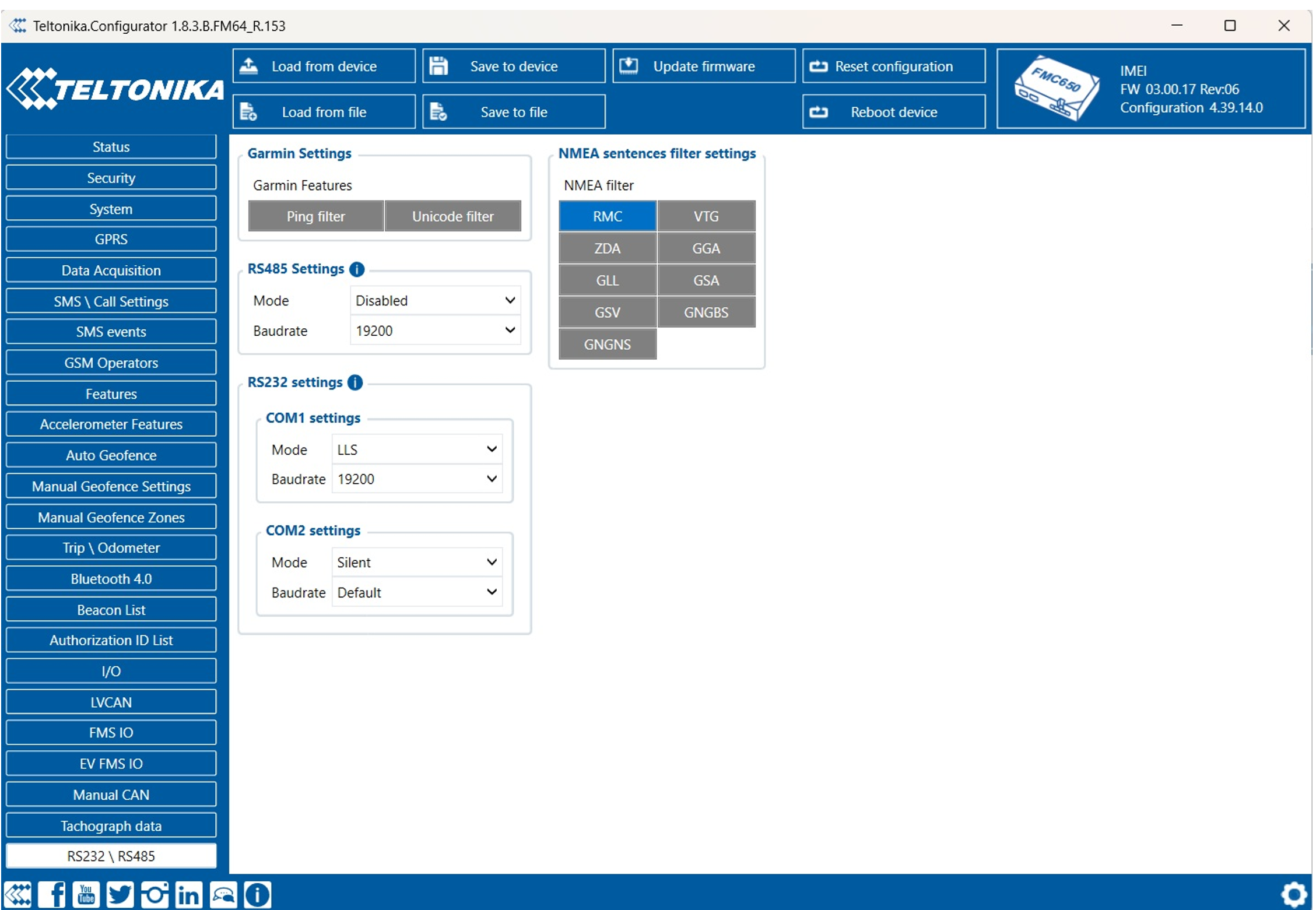

RS232:

19. Under RS232 Settings:

- COM 1 or COM 2 Mode: LLS

- Baudrate: 19200

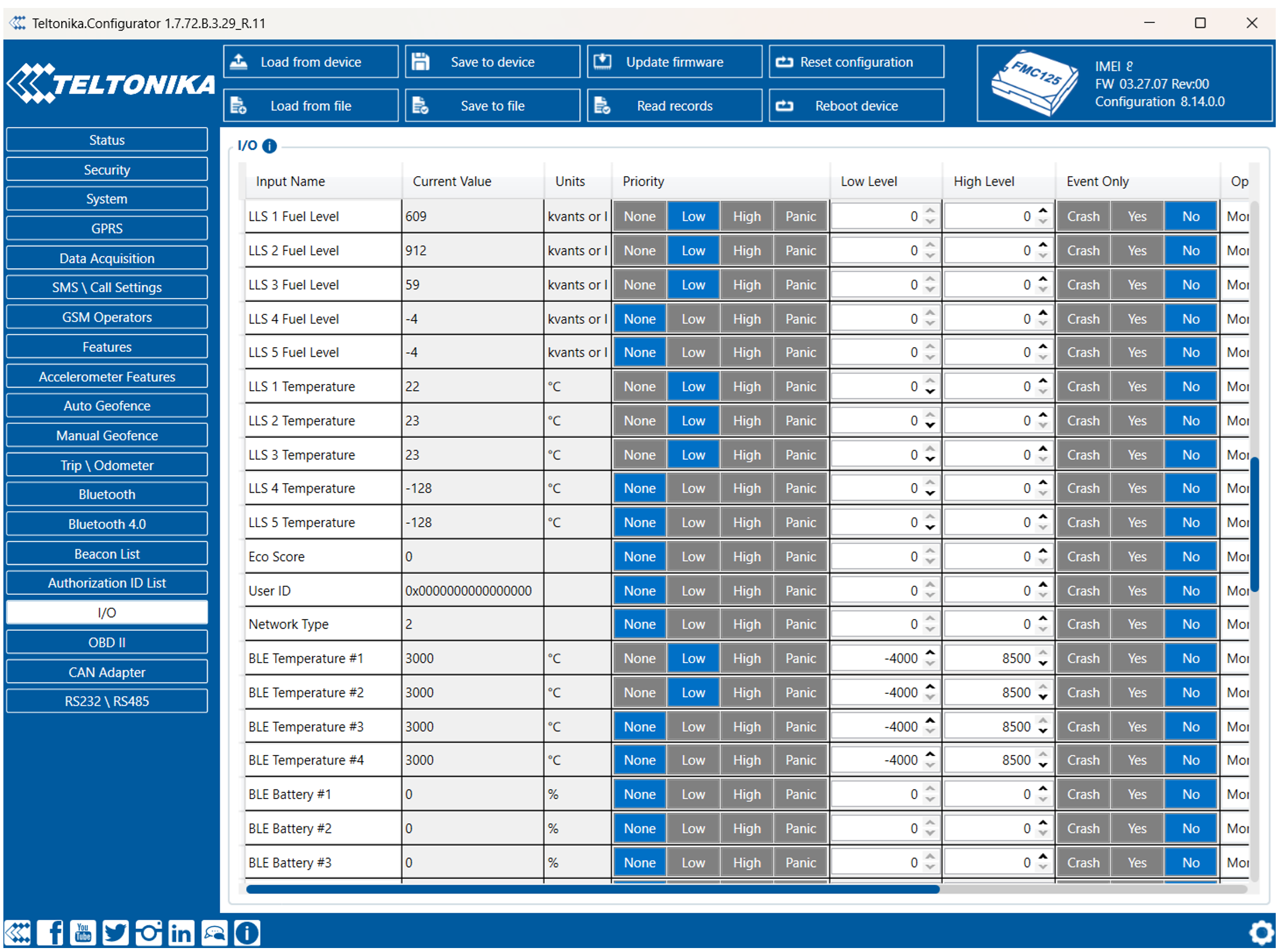

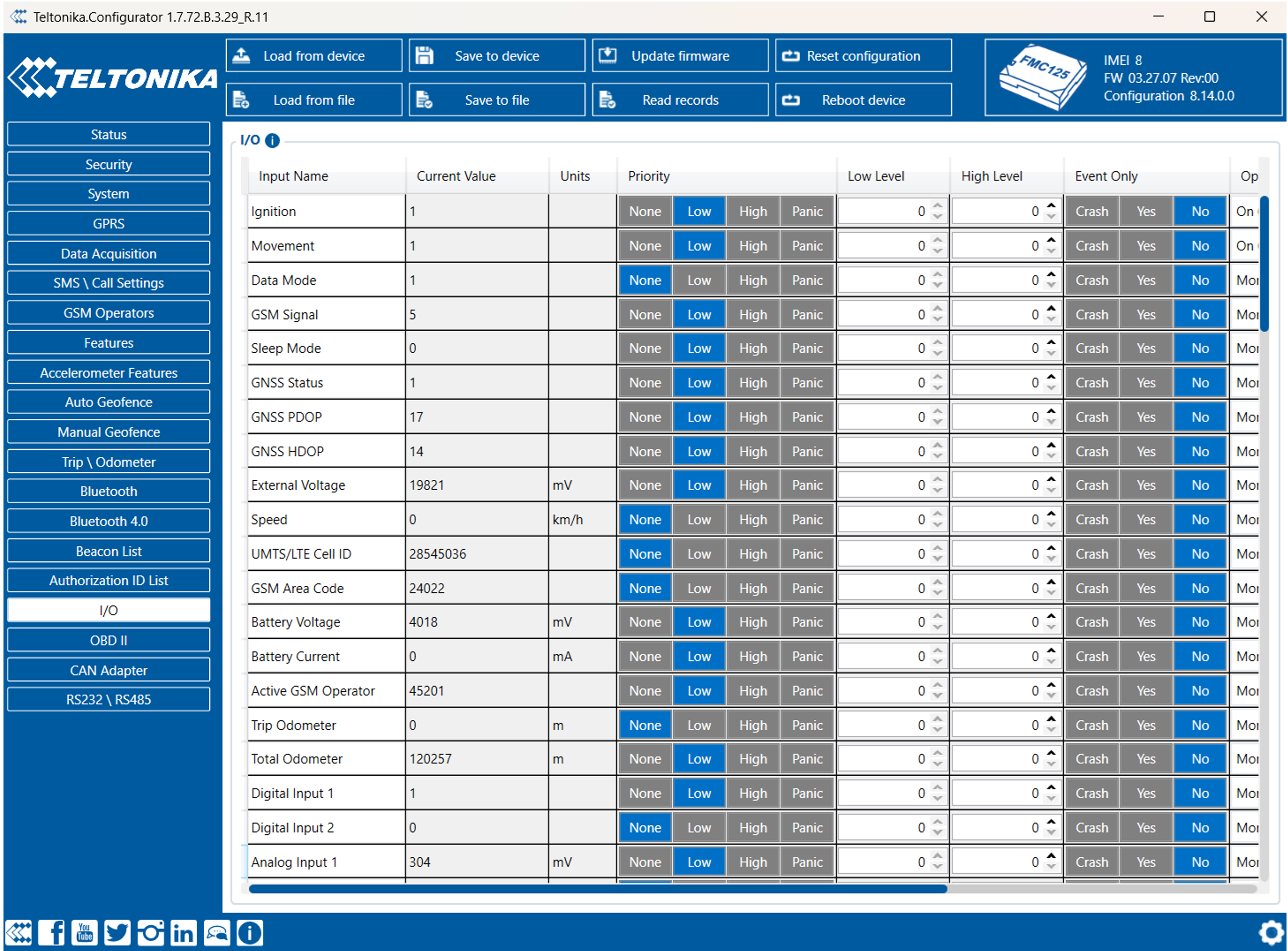

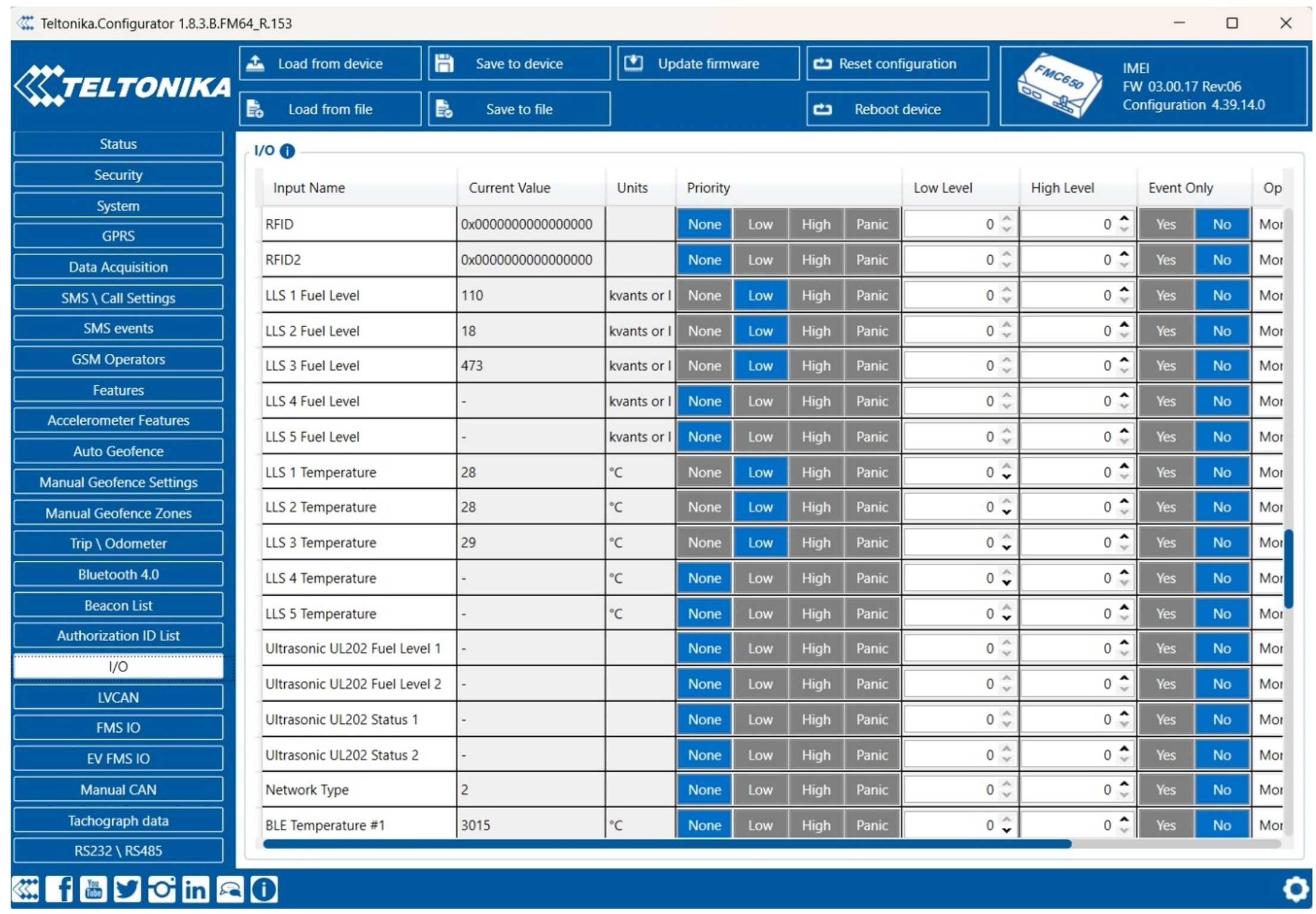

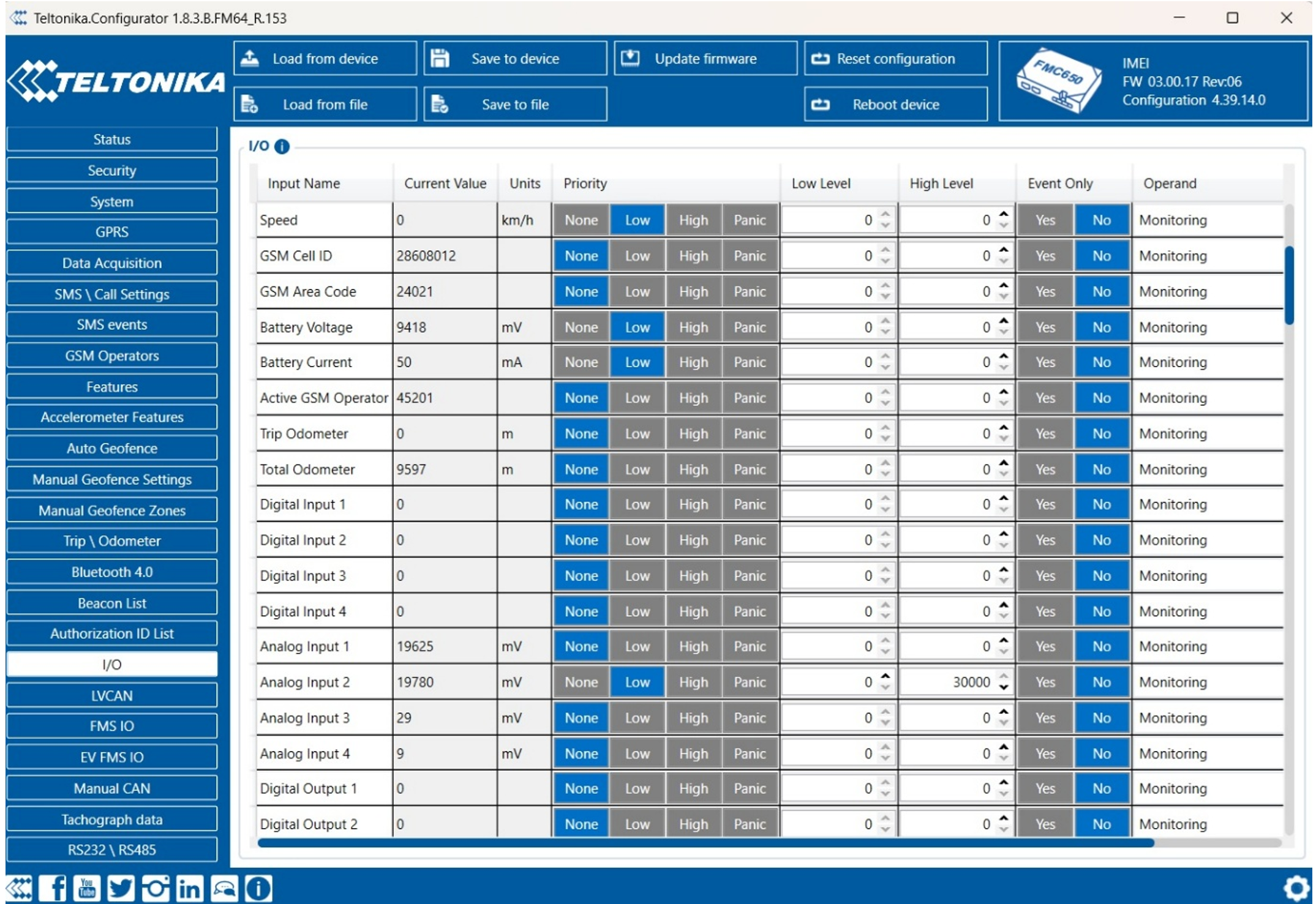

Go to the I/O tab.

Set the priority of:

- LLS 1 Fuel Level – LLS 6 Fuel Level (must match sensors number)

- LLS 1 Temperature – LLS 6 Temperature (must match sensors number)

- Set each of these to LOW priority

In case of use Digital or Analog inputs, set the priority and range accordingly.

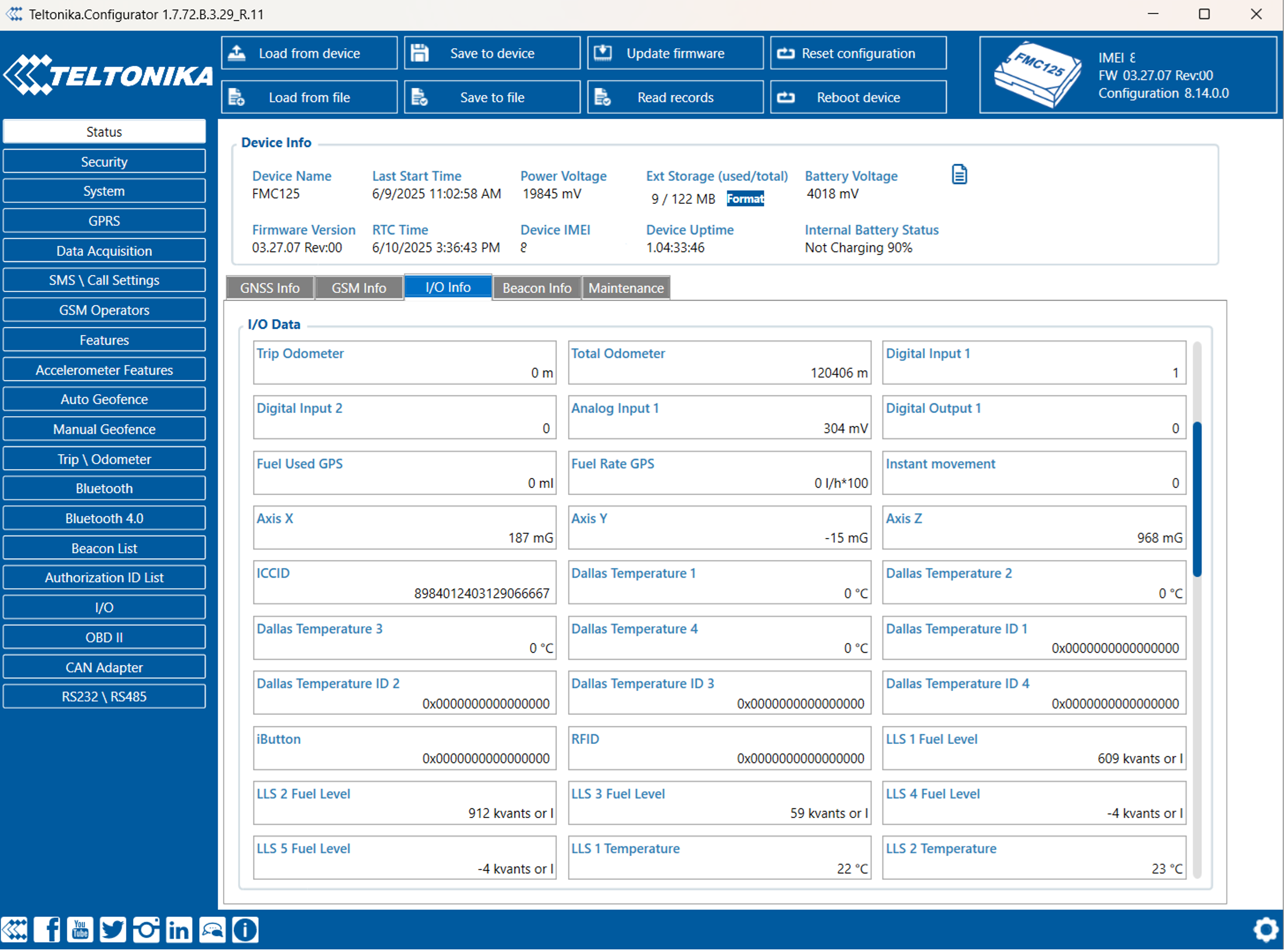

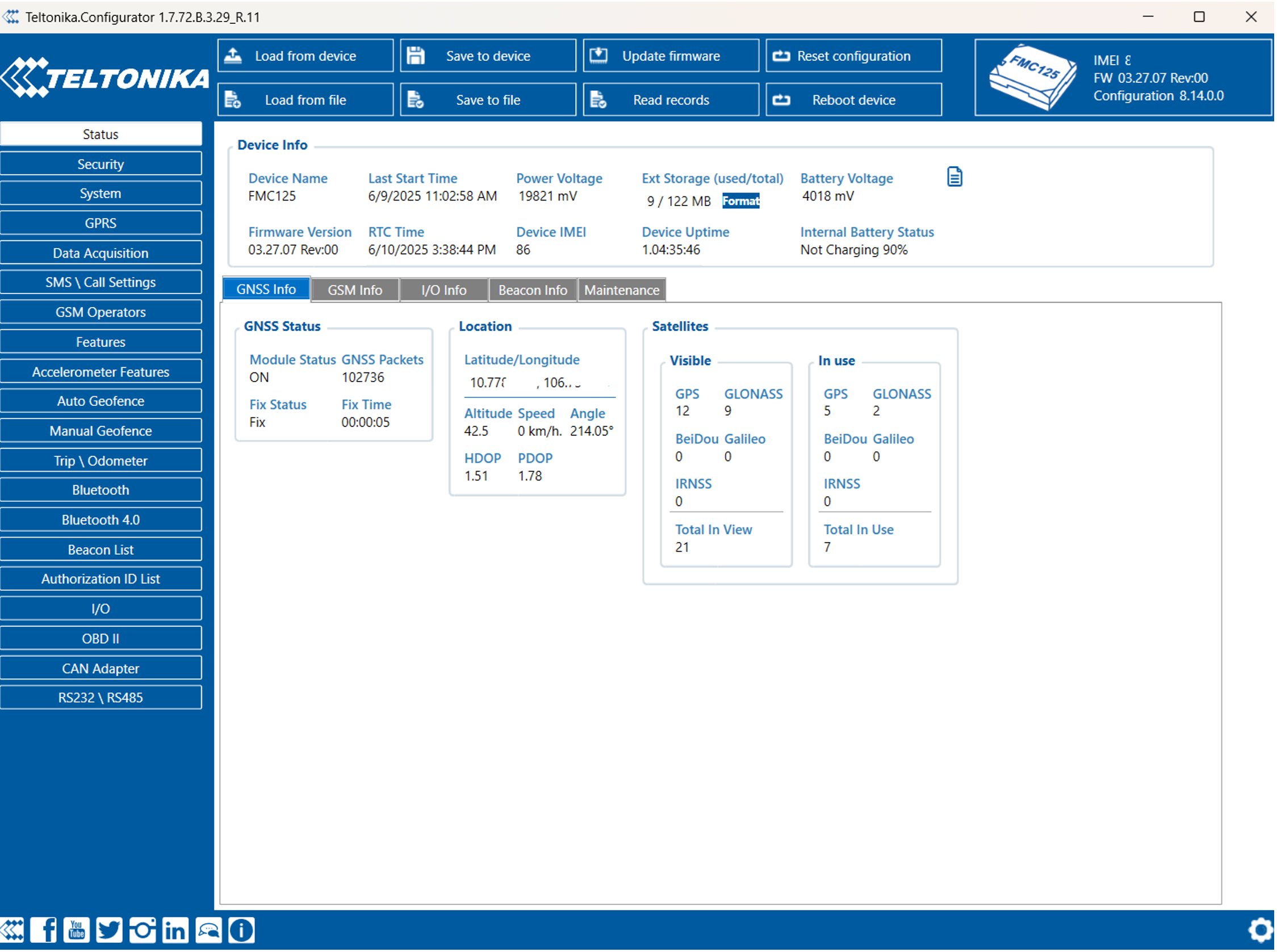

Step 5: Verify Readings

22. Go to the Status tab to confirm data:

- Check the I/O tab.

- Check GNSS info.

- Check GSM info to verify SIM/network connection and server data transmission.

Profile Setup

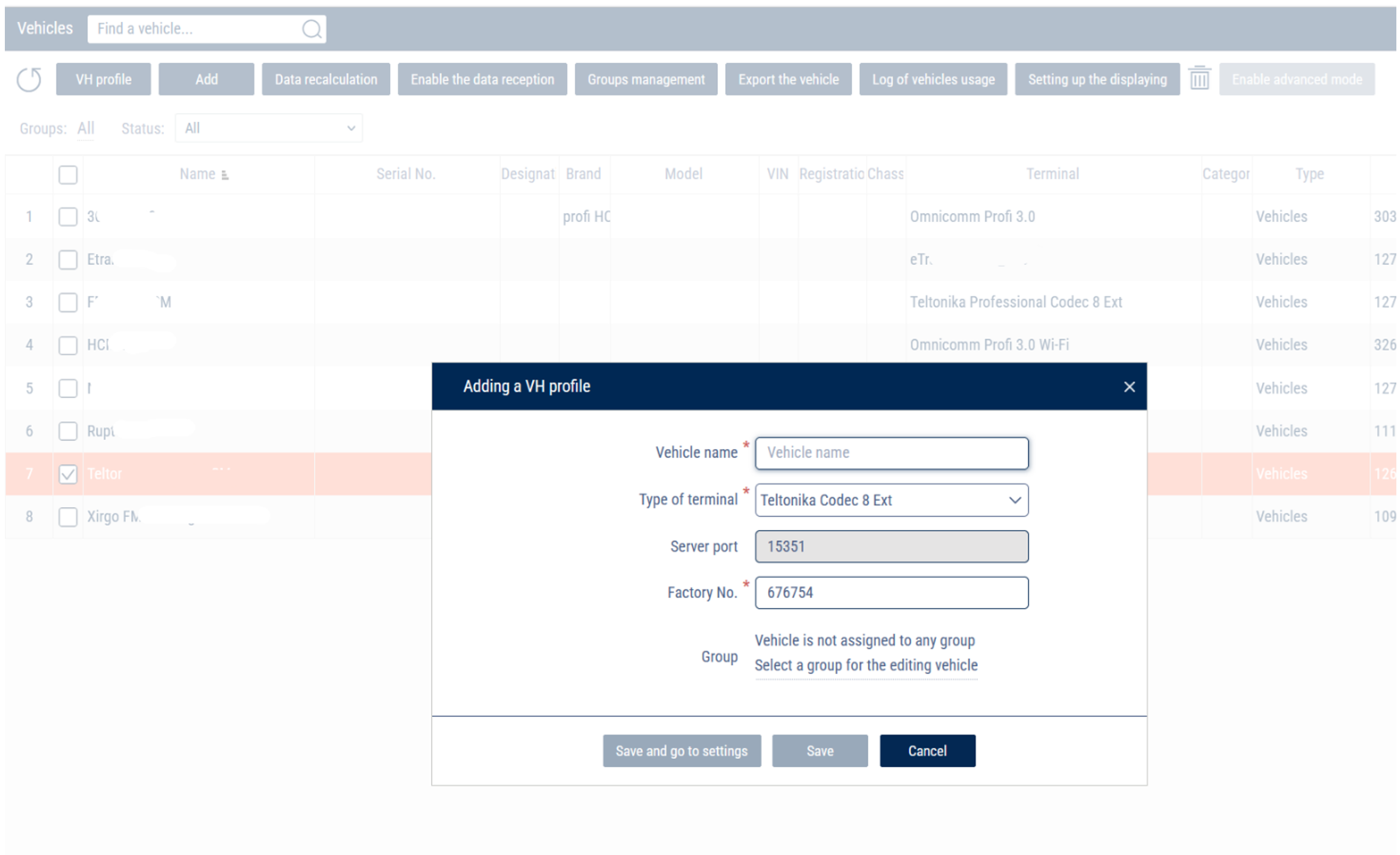

Step 6: Add VH and verify Readings on the platform

23. Log in to your account and open Administration Vehicles tab

- Click Add.

- Choose Type of terminal: Teltonika Codec 8 Ext

- Server port will set automatically 15351 (must fit server port in GPRS tab)

- Put your device's IMEI number in Factory No. field

- Put the name in Vehicle Name field (this name will be displayed in reports)

24. Click on created VH in the list and click VH Profile button.

- Open Profile tab set up settings according manual: https://doc.omnicomm.ltd/en/omnicomm_online-administration/vehicle/add/profile_settings

- In the Fuel parameters section, choose a number of tanks and number of installed LLS.

- Fuel tanks - select the number of fuel tanks installed on a vehicle:

Main only means only one fuel tank is installed on a vehicle

Main and additional means two fuel tanks are installed on a vehicle. For refuellers, the main tank is the reservoir, the additional tank is the engine fuel tank. For the vehicle, the main tank is the engine fuel tank, the additional tank is the fuel tank for the optional equipment.

Multitank means up to 6 fuel tanks are installed on a vehicle. Available to users with established rights to objects: Access to Multitank (see Adding and editing a user profile).

Examples:

- Main tank and single sensor: Common scenario.

- Main tank and 2 sensors and more: In case of a complicated shape or impossibility to install a sensor in the center, two or more sensors are used for measurement level in a single tank.

- Main and additional tank and 2 sensors: A Vehicle has 2 tanks, and each tank is equipped with 1 sensor.

- Main and additional tank and 3 or more sensors: A Vehicle has 2 tanks, and each tank is equipped with 1 or more sensors.

- Main tank + Multitank or Main and additional tank + Multitank is scenarios for fuel bowser, gas stations e.t.c. For each cistern or isolated compartment could be assigned one or several sensors.

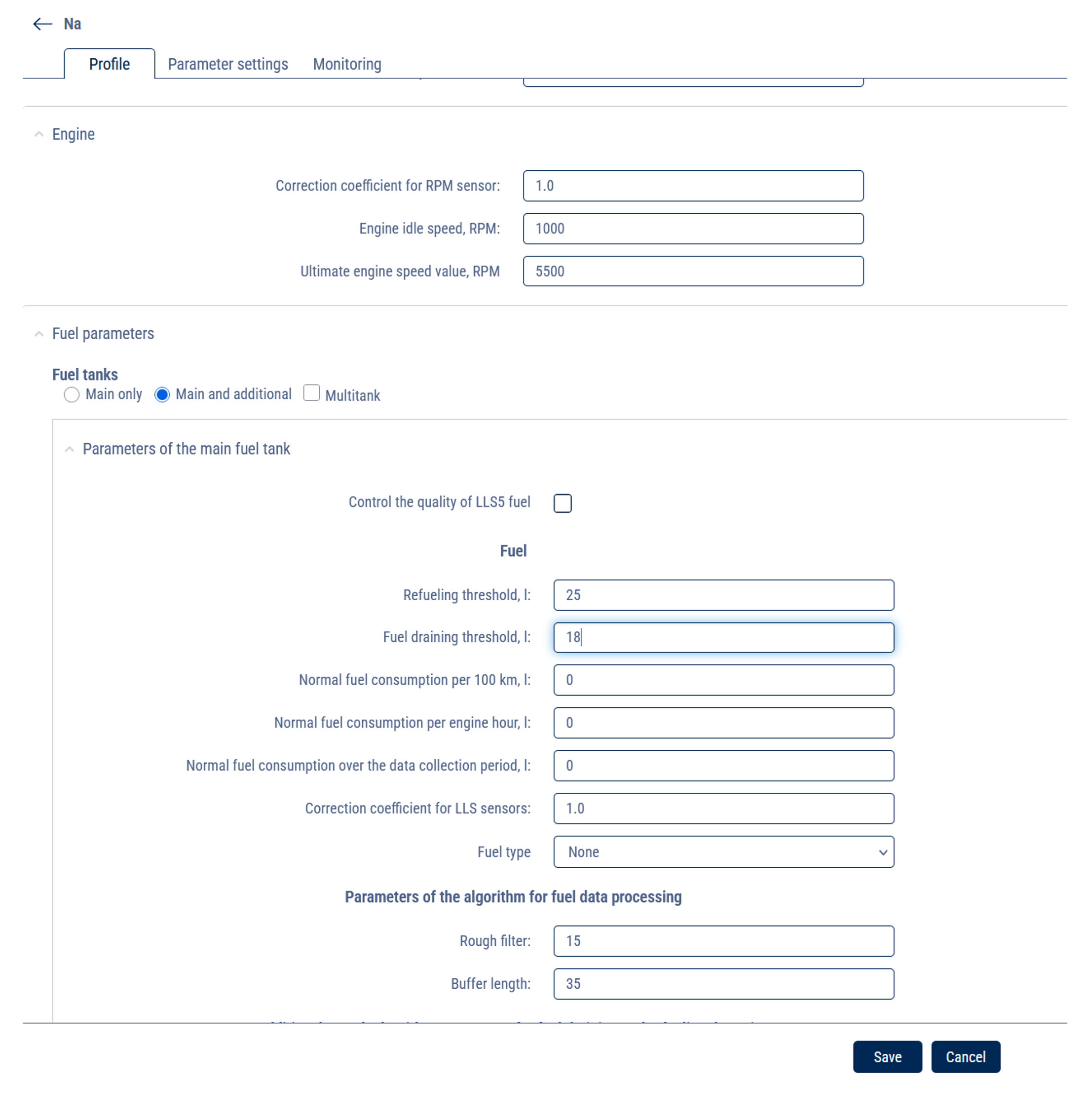

For each tank set up Parameters of the fuel tank:

- Set up Refueling threshold (recommended value 7% of tank volume, number depends on condition);

- Set up Fuel draining threshold (recommended value 7% of tank volume, number depends on condition);

- Set up Rough filter (depends on road condition);

- Set up Buffer length (depends on road condition);

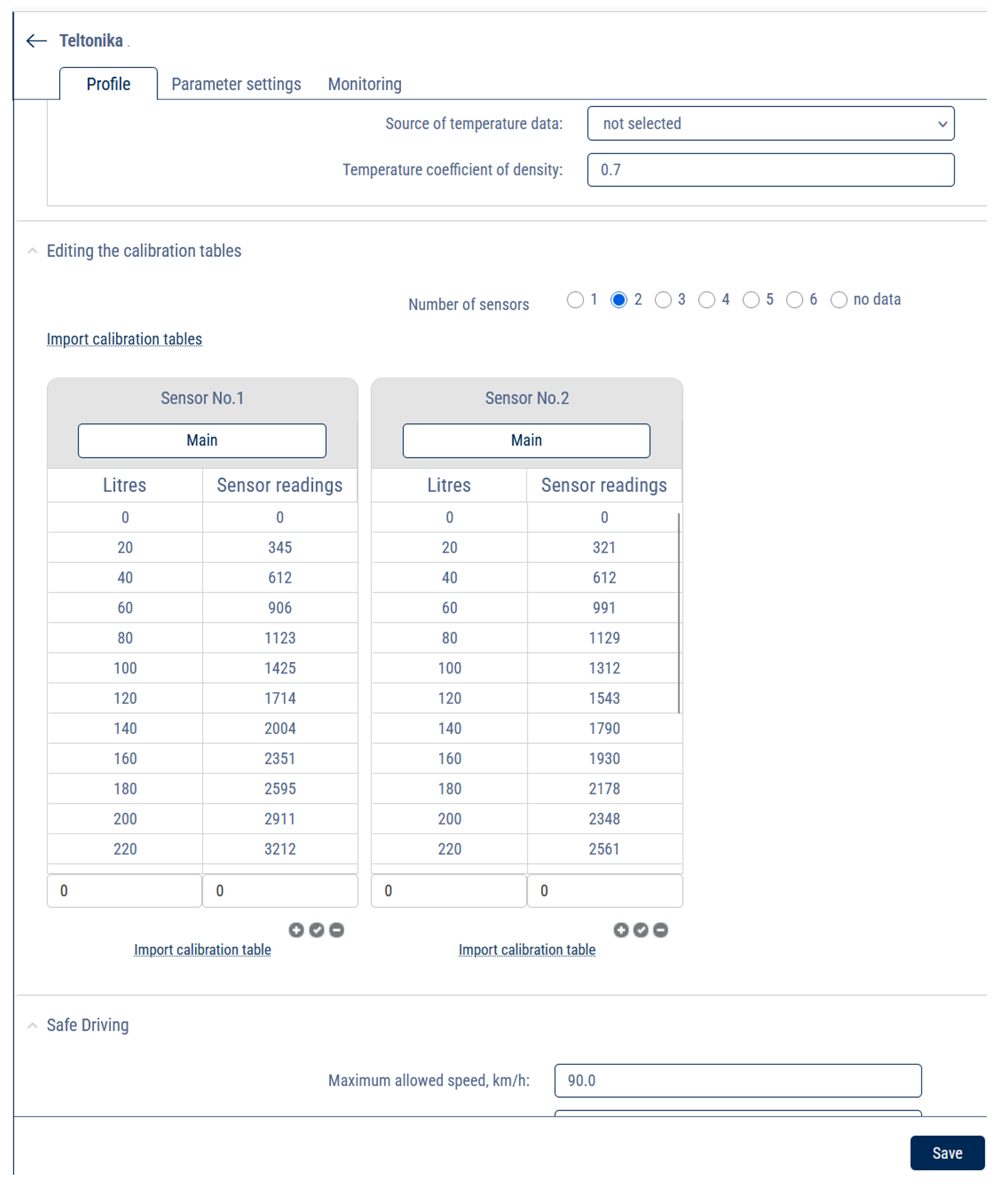

- In Editing the calibration tables, import calibration tables or fill it manually and link sensors to the tanks.

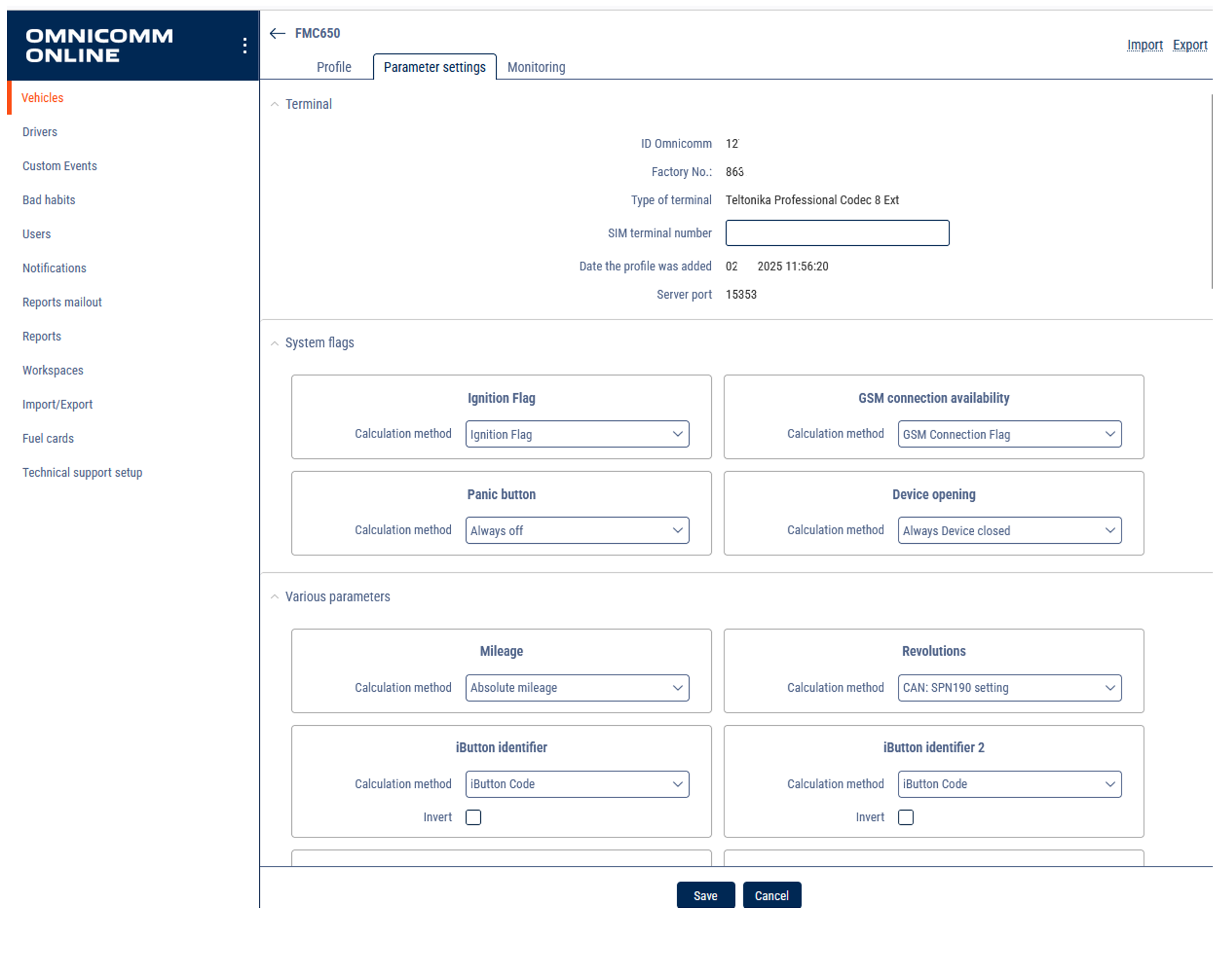

25. Open Parameter settings tab:

- Choose and link the necessary parameters.

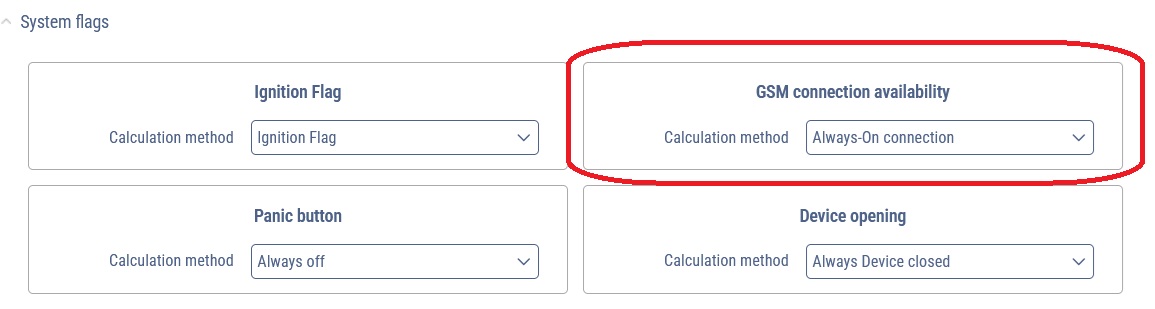

For System flags:

* Choose GSM connection availability: Always-On connection.

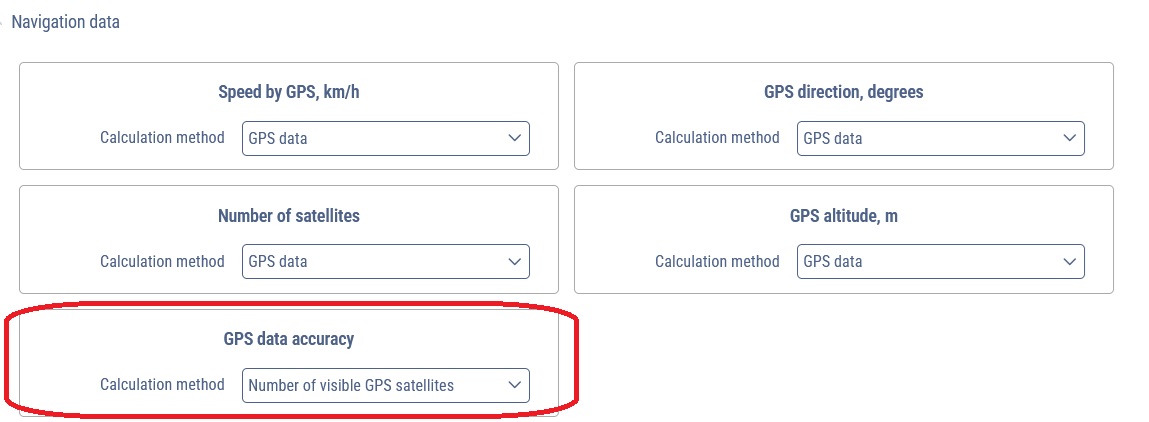

For Navigation data:

* Choose GPS data accuracy: Number of visible GPS satellites.

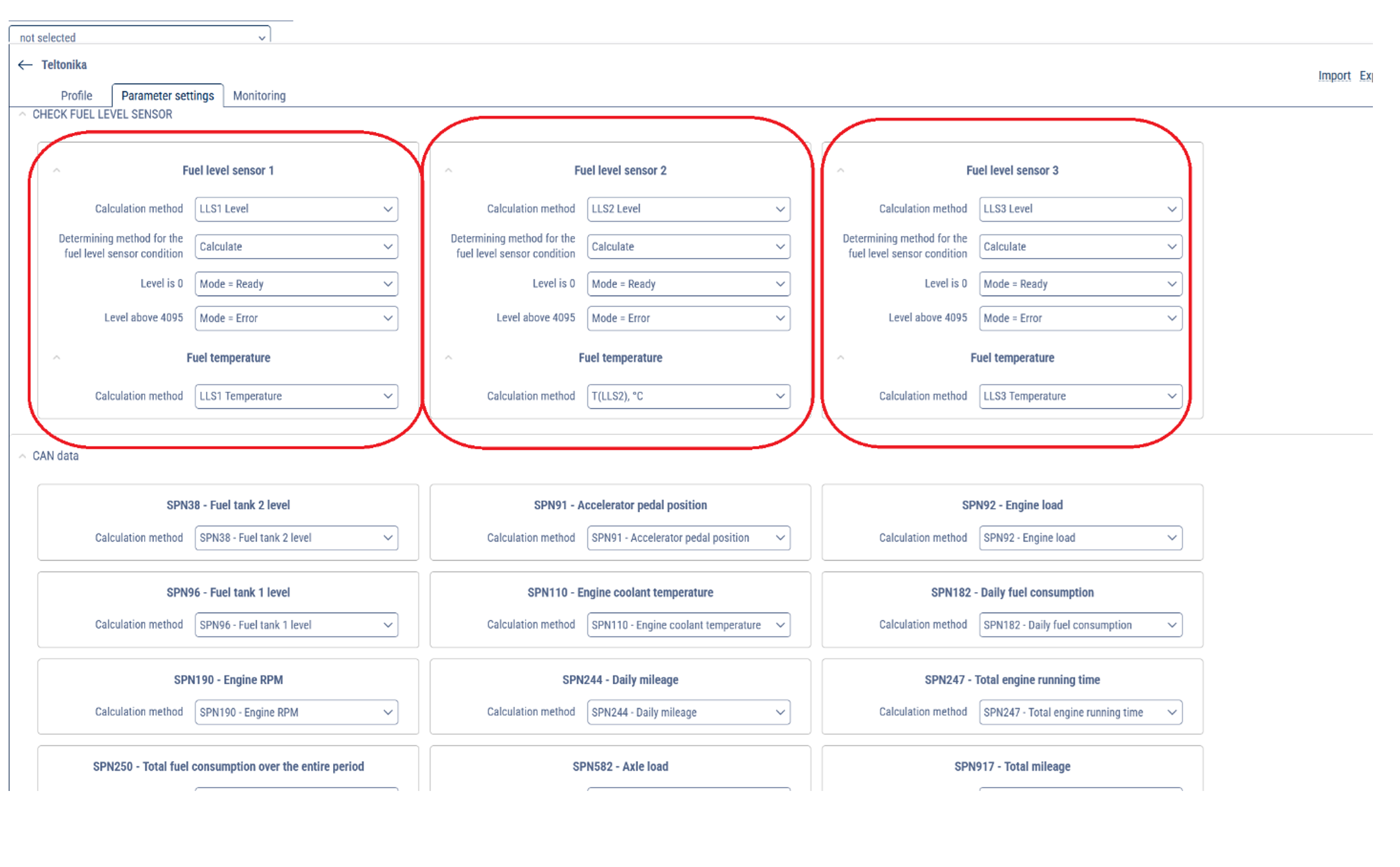

- For CHECK FUEL LEVEL SENSOR choose source of data for each LLS:

For Fuel level sensor 1:

- Calculation method: LLS1 Level

- Determining method for the fuel level sensor condition: Calculate

- Level is 0: Mode = Ready

- Level above 4095: Mode = Error

- Fuel temperature Calculation method: LLS1 Temperature

For Fuel level sensor 2:

- Calculation method: LLS2 Level

- Determining method for the fuel level sensor condition: Calculate

- Level is 0: Mode = Ready

- Level above 4095: Mode = Error

- Fuel temperature Calculation method: LLS2 Temperature

Same for each sensor.

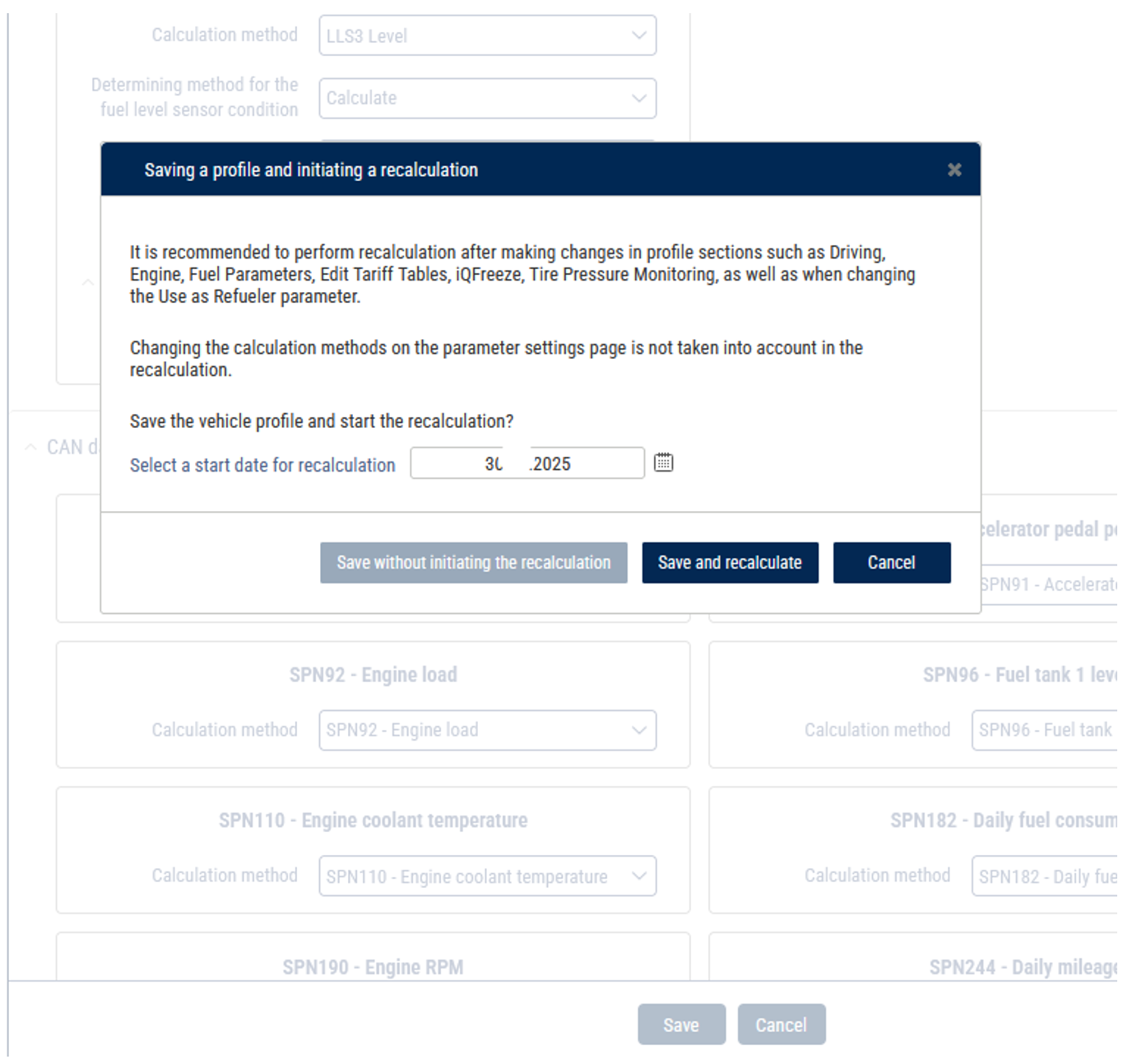

- Click Save and recalculate.

- Choose VH in the list and click VH Profile button.

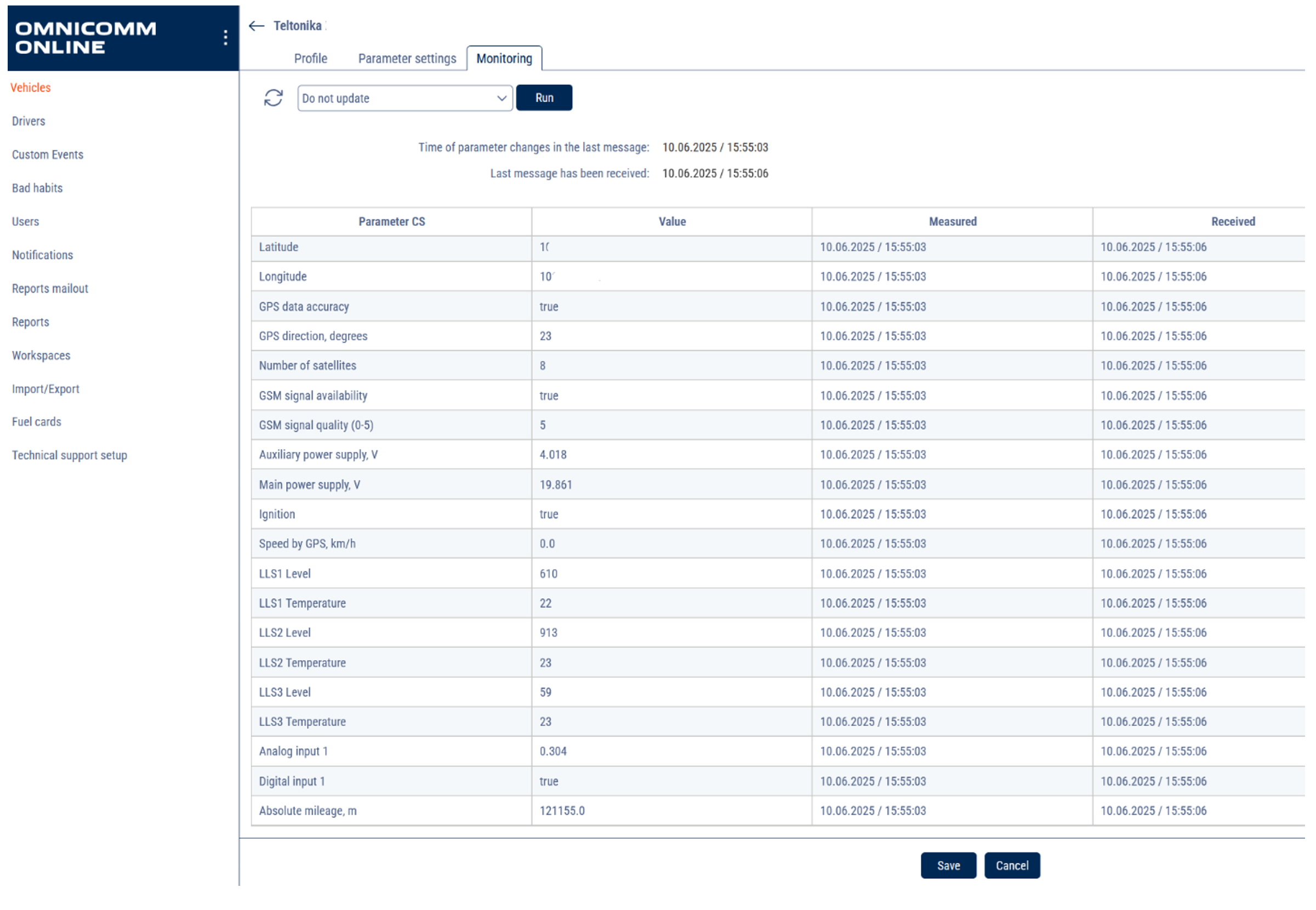

- Open Monitoring tab: check the received values.

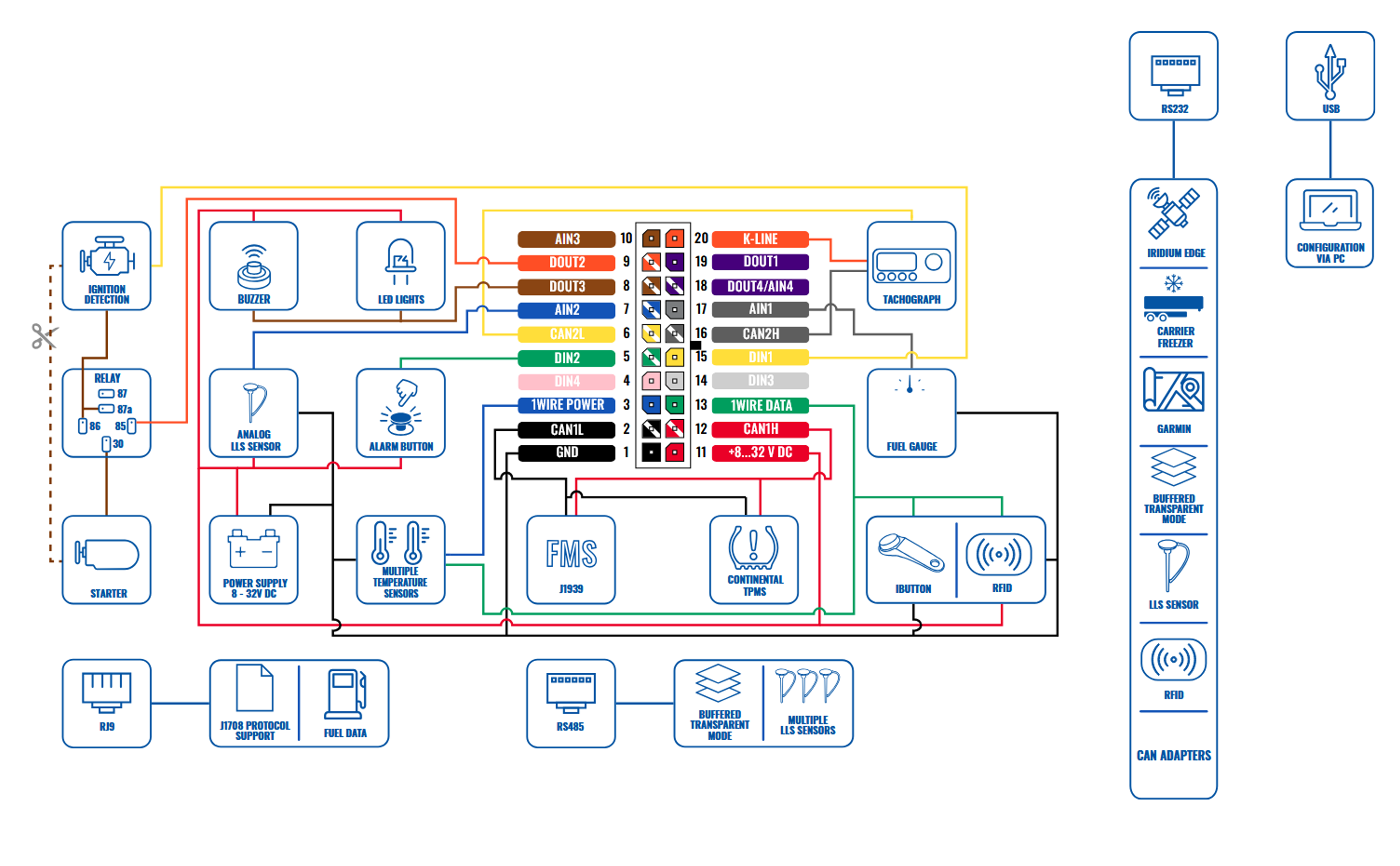

Teltonika FMC650

Teltonika FMC650 is a direct successor to current most popular 4G PROFESSIONAL lineup device – FMC640. FMC650 has 4G (LTE Cat 1) network coverage including 2G (GSM) fallback compatibility. Device equipped with GNSS and LTE modules, external GNSS and LTE antennas. Separate GNSS module improves the accuracy of the track, making FMC650 more suitable for free flow electronic tolling system integration. Compared to FMC640 – FMC650 has a new processor that improves the devices computation power along with increased device internal memory it can be tailored to more specific use cases. Switchable CAN terminators that will allow you to use the device in CAN network with numerous nodes. Lastly, it can be powered via USB for easier configuration process. All the features that are supported by FMC640 is also supported by FMC650, therefore it will maximize your fleet efficiency with features like FMS CAN data (J1939), fuel CAN data (J1708), tachograph live data (K-Line), remote tachograph file download, various third party RS232 or RS485 devices support and Dual-SIM or eSIM compatibility. Terminal is suitable for applications like international logistics, refrigerated transport, agriculture, construction & mining, security & emergency services and even more.

FMC650 supports up to 5 digital LLS sensors through RS-485 interface, or single LLS through 232, it has 4 analog inputs, 4 digital inputs and could be used as a refueler in Omnicomm Online.

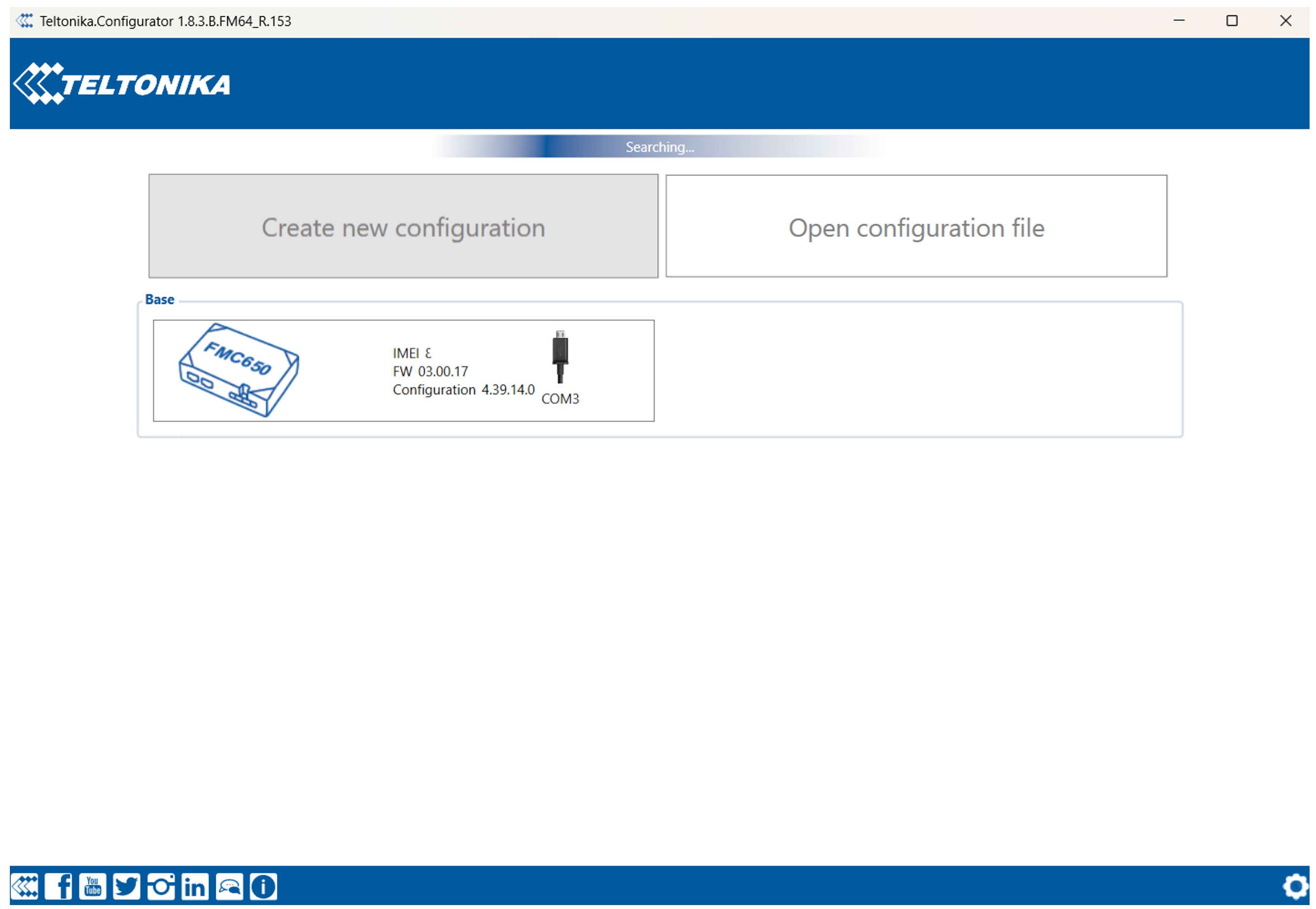

Install Software

1. Download & install Teltonika Configurator for your OS:

- Unordered List ItemDownload Configurator

2. Install COM Port Drivers for PC communication:

- Unordered List ItemDownload Drivers

Mounting

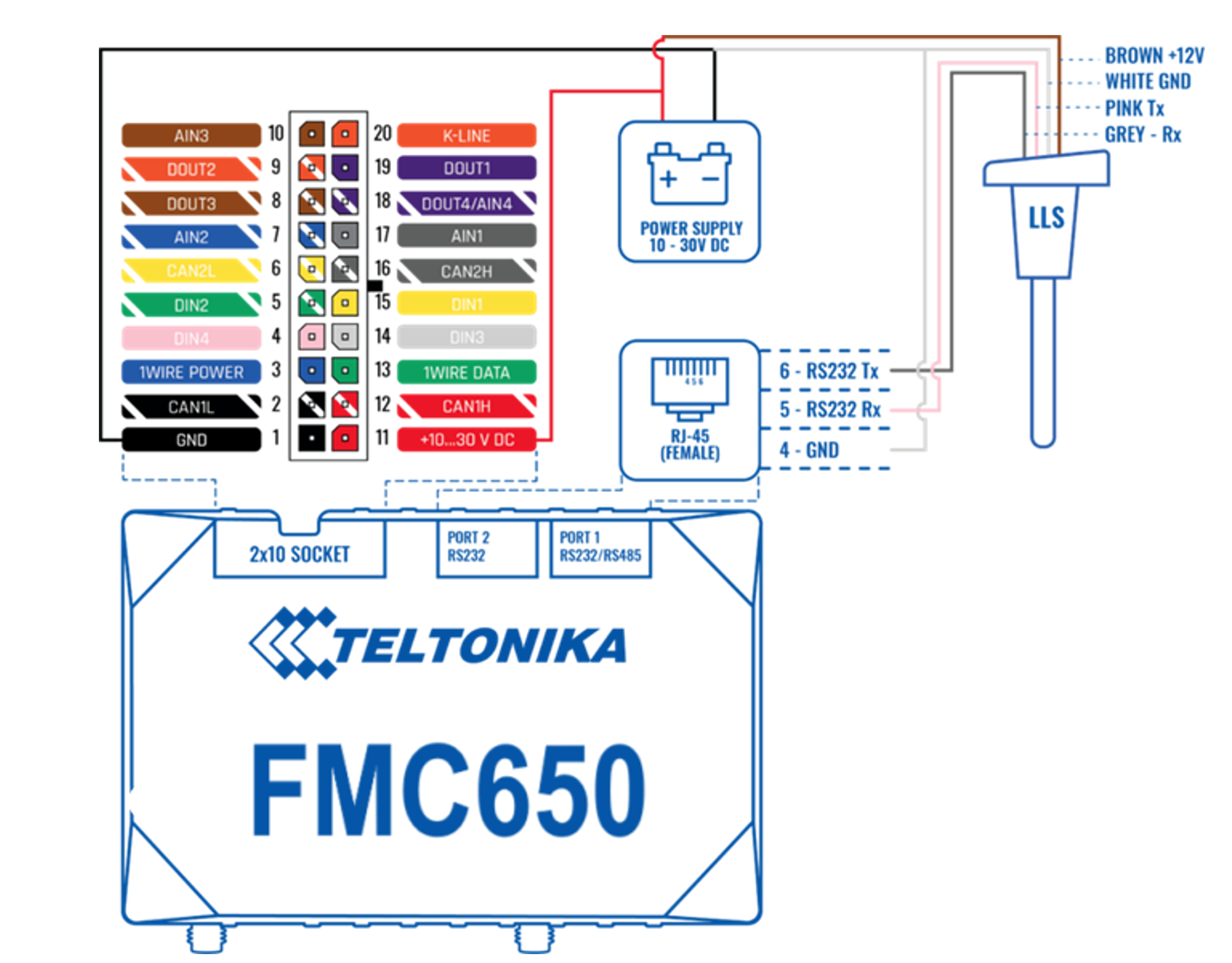

Fuel Sensor Connection

FMC 650 MOUNTING RECOMMENDATIONS

CONNECTING WIRES

- Wires should be fastened to the other wires or non-moving parts. Try to avoid heat emitting and moving objects near the wires.

- The connections should not be seen very clearly. If factory isolation was removed while connecting wires, it should be applied again.

- If the wires are placed in the exterior or in places where they can be damaged or exposed to heat, humidity, dirt, etc., additional isolation should be applied.

- Wires cannot be connected to the board computers or control units.

CONNECTING POWER SOURCE

- Be sure that after the car computer falls asleep, power is still available on chosen wire. Depending on car, this may happen in 5 to 30 minutes period.

- When module is connected, measure voltage again to make sure it did not decrease.

- It is recommended to connect to the main power cable in the fuse box.

- Use 3A, 125V external fuse.

CONNECTING IGNITION WIRE

- Be sure to check if it is a real ignition wire i. e. power does not disappear after starting the engine.

- Check if this is not an ACC wire (when key is in the first position, most of the vehicle electronics are available).

- Check if power is still available when you turn off any of vehicles devices.

- Ignition is connected to the ignition relay output. As alternative, any other relay, which has power output when ignition is on, may be chosen.

CONNECTING GROUND WIRE

- Ground wire is connected to the vehicle frame or metal parts that are fixed to the frame.

- If the wire is fixed with the bolt, the loop must be connected to the end of the wire.

- For better contact scrub paint from the spot where loop is going to be connected

RS485 Digital Sensors Connection

Connect a single LLS via RS232 port.

Connect FMC650 Tracker

1. Use the USB/2-USB cable or another suitable cable to connect the FMC650 tracker to your PC.* *A cable with an USB/2-USB connector is not included in the FMC650 delivery pack.

2.Open Teltonika Configurator and wait for it to detect the connected device(1- 2 min). The configurator could restart after the recognition tracker.

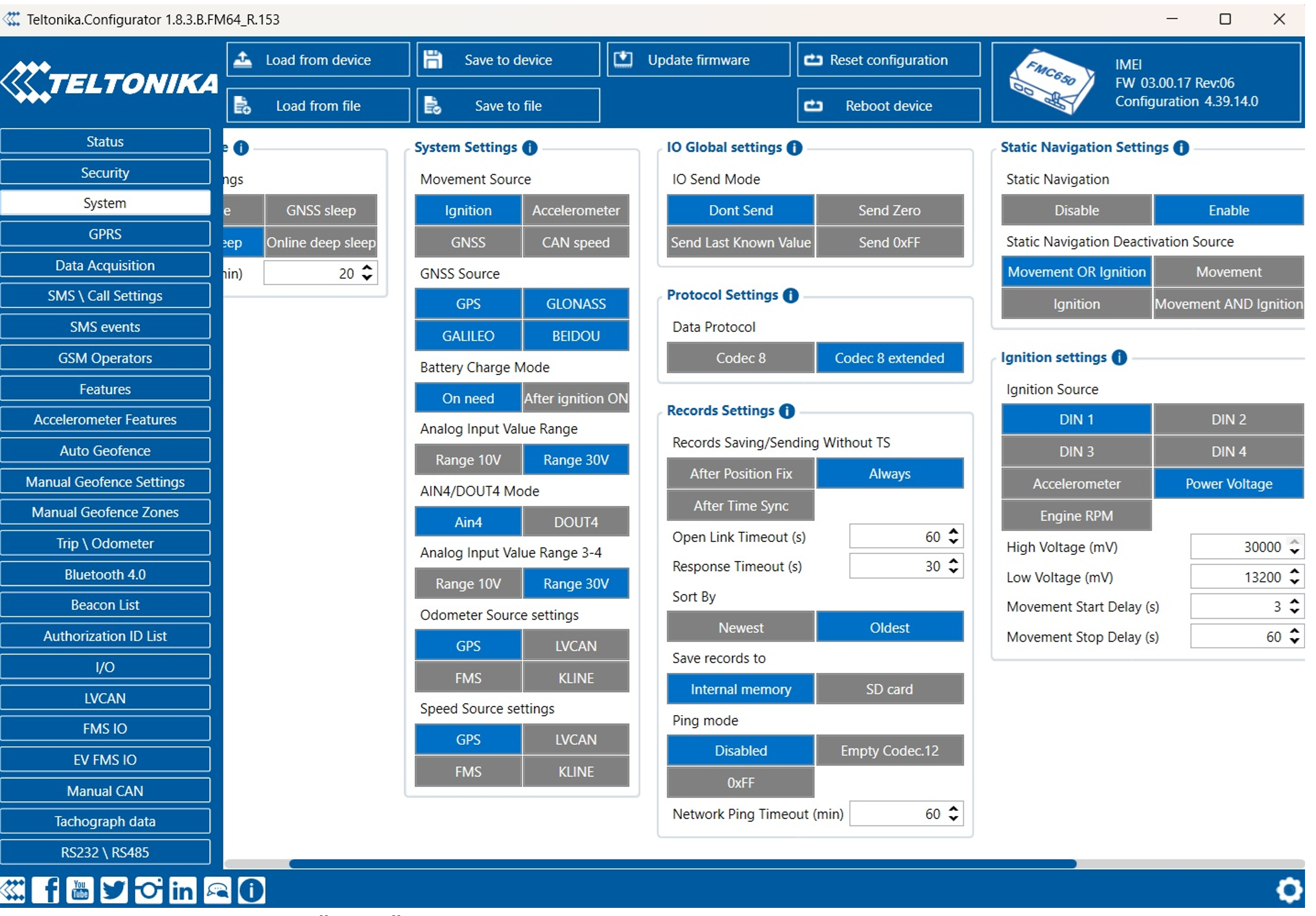

Configuration

Network Configuration

1. When your device appears, enter the configuration window.

2. Go to the System tab.

Set ignition input:

- The ignition wire must be connected to DIN1 input.

- Under Ignition Source, select the corresponding DIN1 flag.

Under Data Protocol, select one of the following:

- Recommended: Codec 8 or Codec 8 Extended

- Note: Choosing a protocol defines which port you'll configure in the GPRS tab.

Under “Records Settings”.

- Set Sort by: Oldest

3. Go to the GPRS tab.

Configure APN and password if required by your SIM card provider.

Under Server #1 Settings, enter:

* Domain: 185.9.185.254 or convert.omnicomm.ru * Port:

Codec 8 Professional: 15352 Codec 8 Professional Extended: 15353

4.Protocol: TCP.

LLS sensors Settings

RS485:

1. Open the RS232/RS485 tab. 2. Under RS485 Settings:

* Mode: LLS * Baudrate: 19200 (must match sensor setting)

3. Under RS485 LLS Sensors:

- Set LLS 1 Address: 1

- Set LLS 2 Address: 2, etc.

- (Sensor IDs must match the ones configured on the LLS sensors.)

RS232:

4. Under RS232 Settings:

- Com 1 or Com 2 Mode: LLS

- Baudrate: 19200

5. Go to the I/O tab.

Set the priority of:

- LLS 1 Fuel Level – LLS 6 Fuel Level (must match sensors number)

- LLS 1 Temperature – LLS 6 Temperature (must match sensors number)

- Set each of these to LOW priority

In case of use Digital or Analog inputs, set the priority and range accordingly.

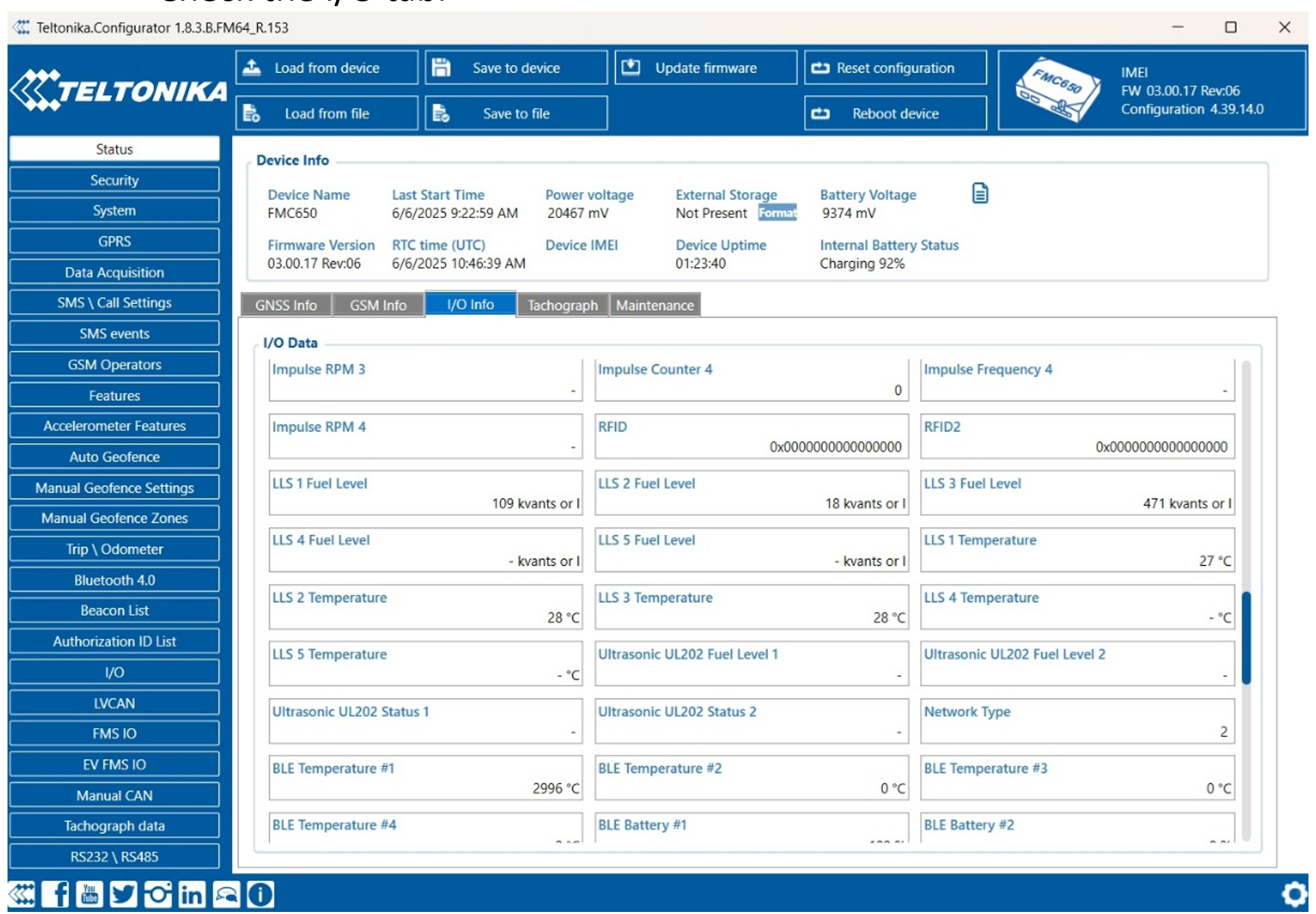

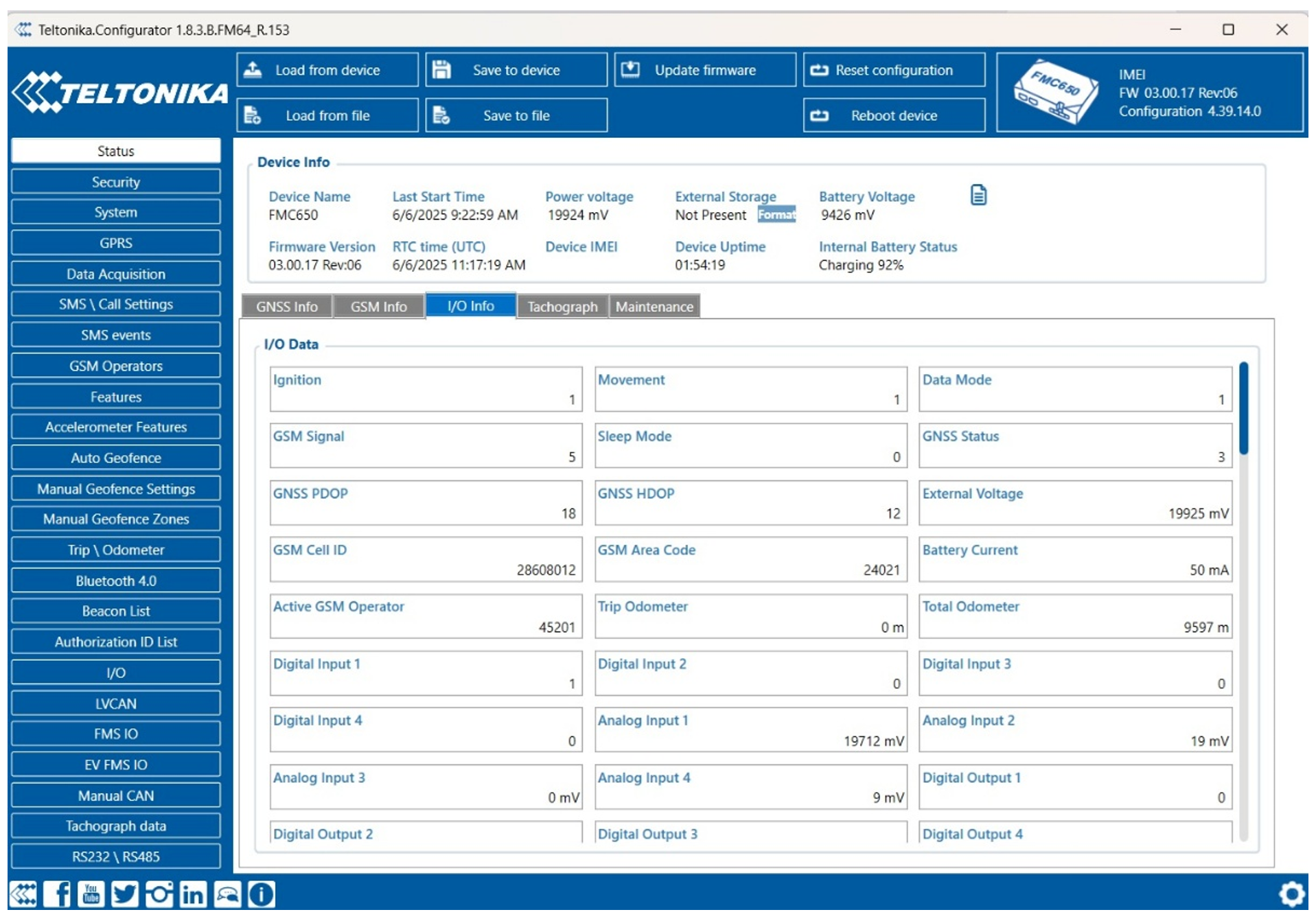

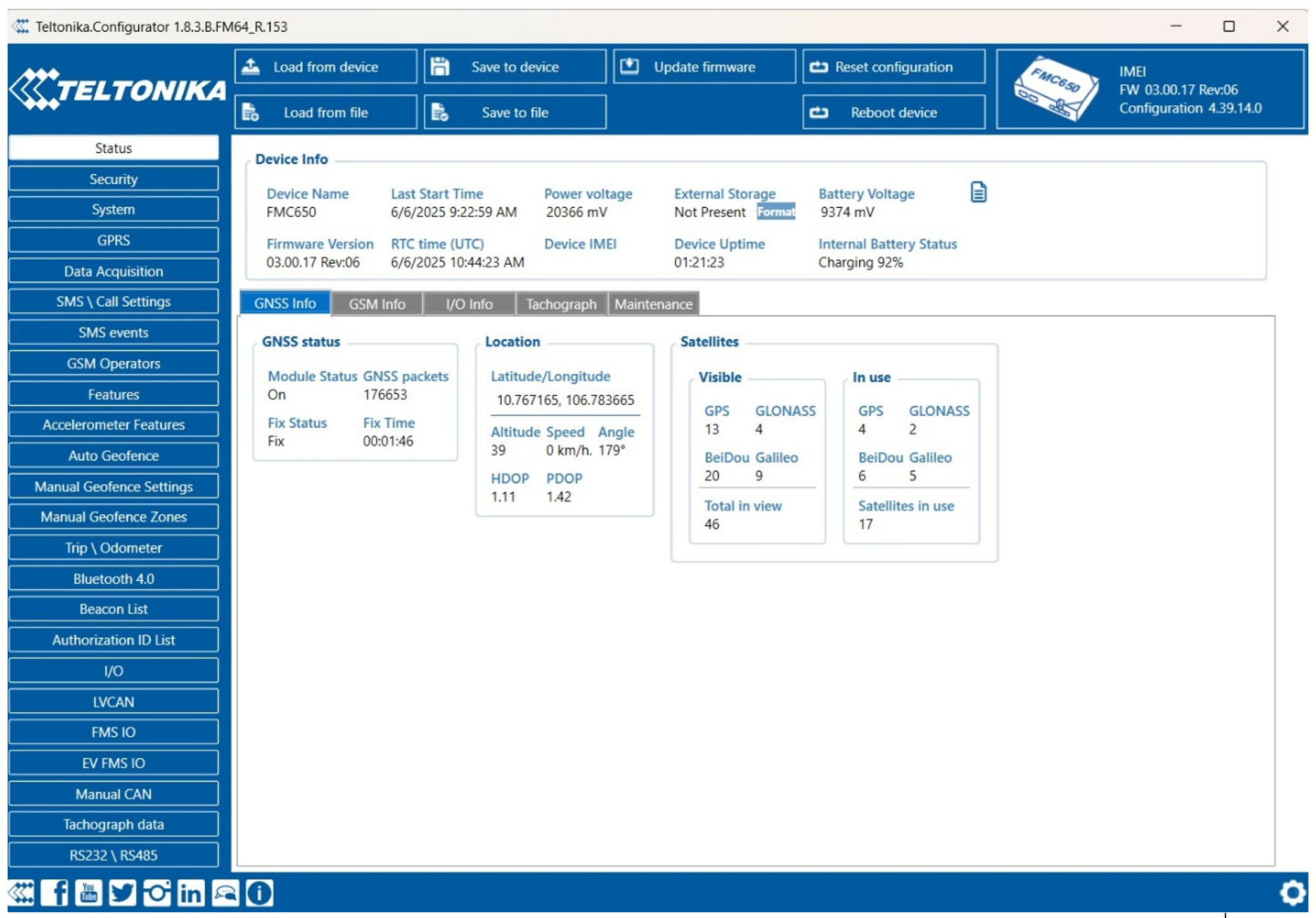

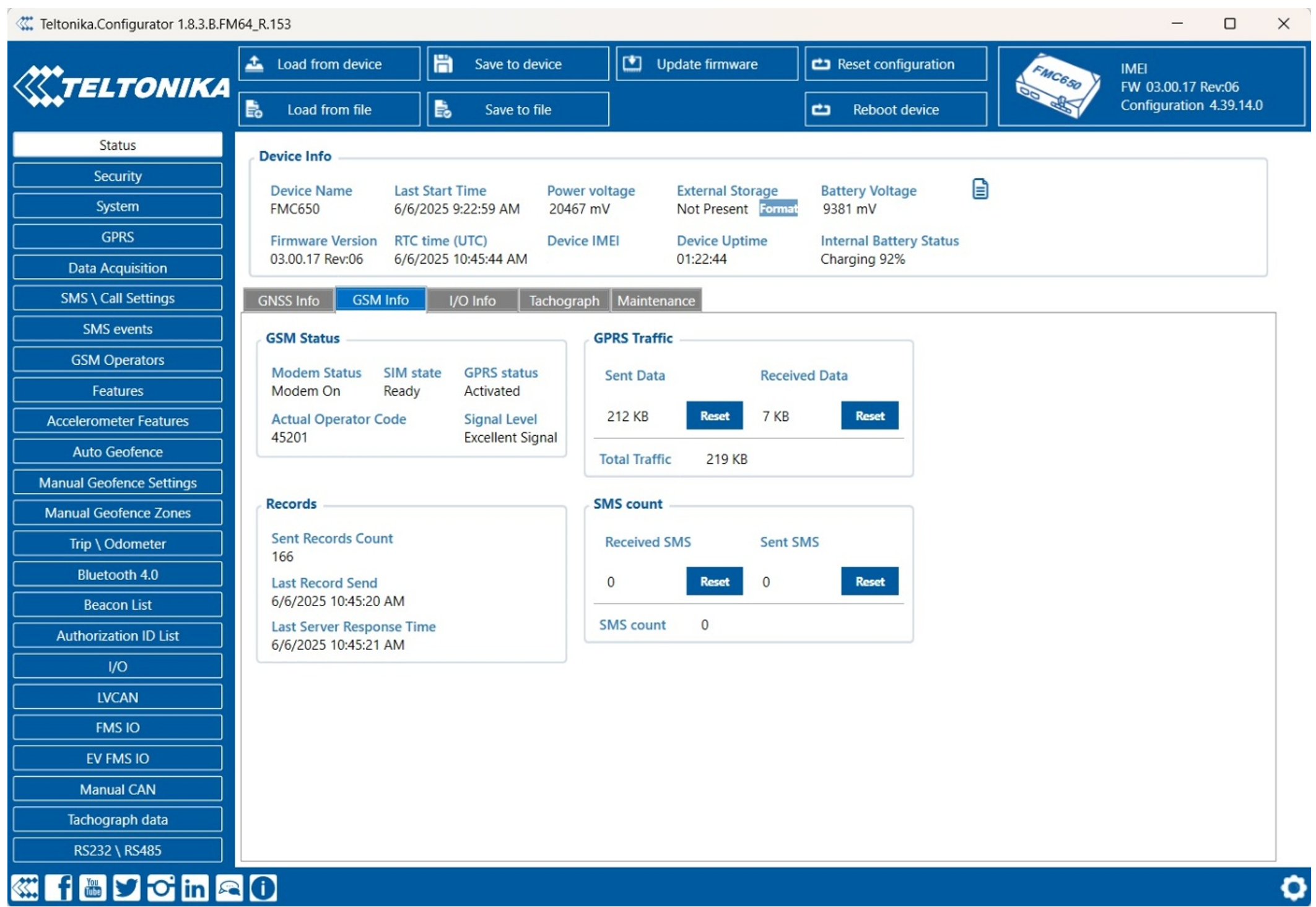

Verify Readings

Go to the Status tab to confirm data:

- Check the I/O tab.

- Check GNSS info.

- Check GSM info to verify SIM/network connection and server data transmission:

Add VH and verify Readings on the platform

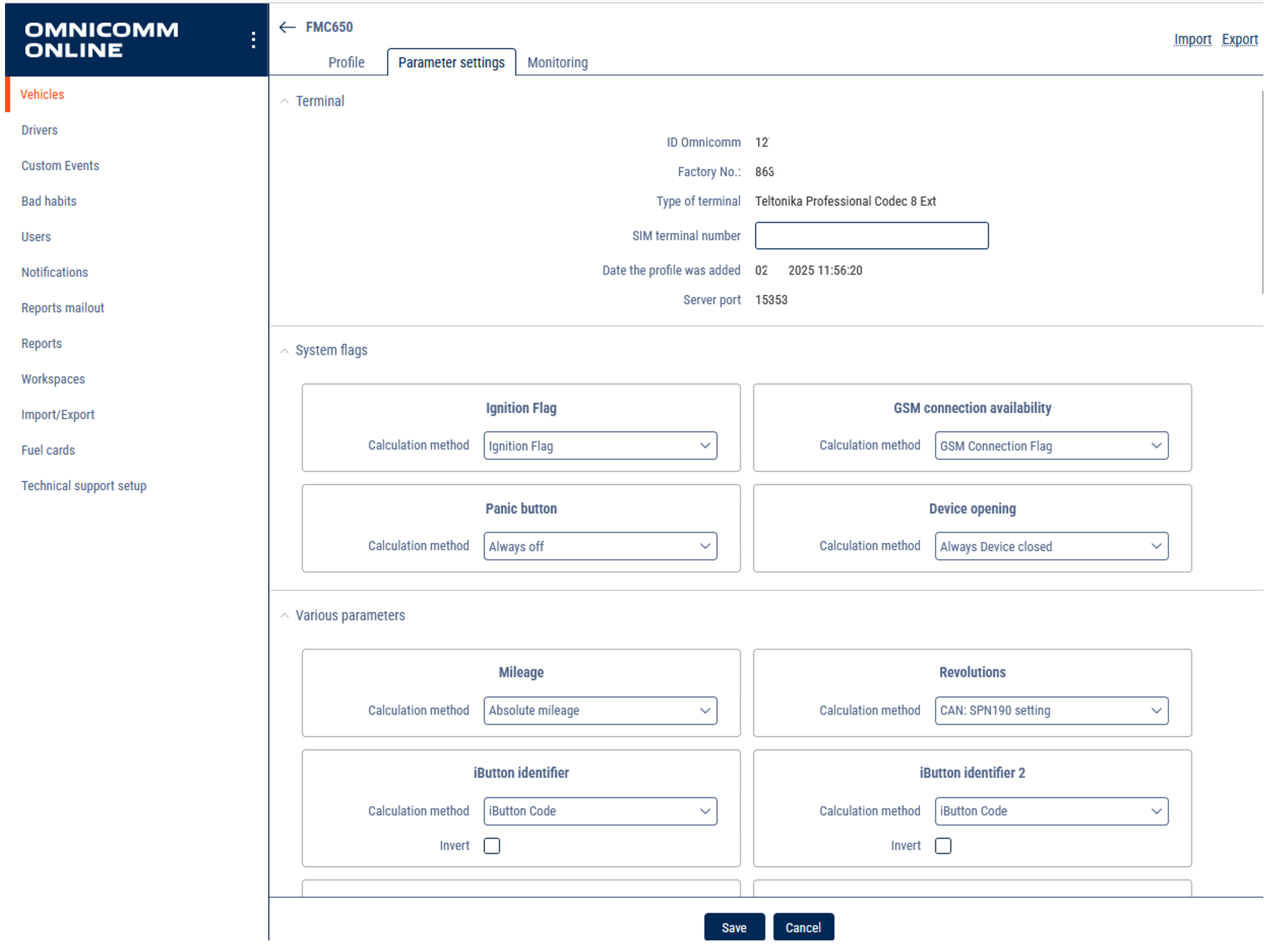

Profile Setup

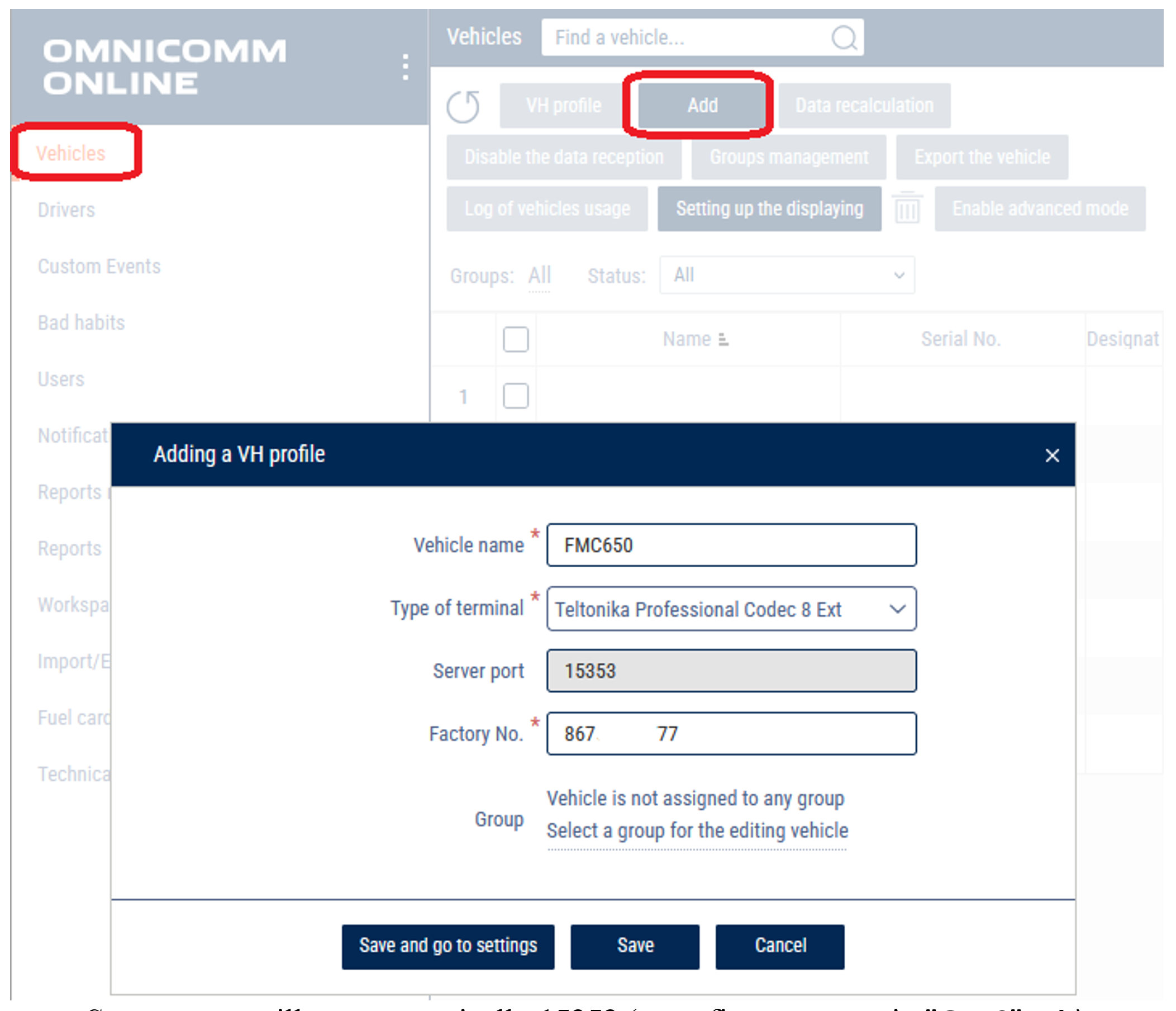

Log in in your account and open Administration-Vehicles tab

- Click Add.

- Choose Type of terminal: Teltonika Professional Codec 8 Ext

- Server port will set automatically 15353 (must fit server port in “GPRS” tab)

- Put your device's IMEI number in Factory No. field

- Put the name in Vehicle Name field (this name will be displayed in reports)

Click on created VH in the list and click VH Profile button

- Open Profile tab set up settings according manual: https://doc.omnicomm.ltd/en/omnicomm_online-administration/vehicle/add/profile_settings

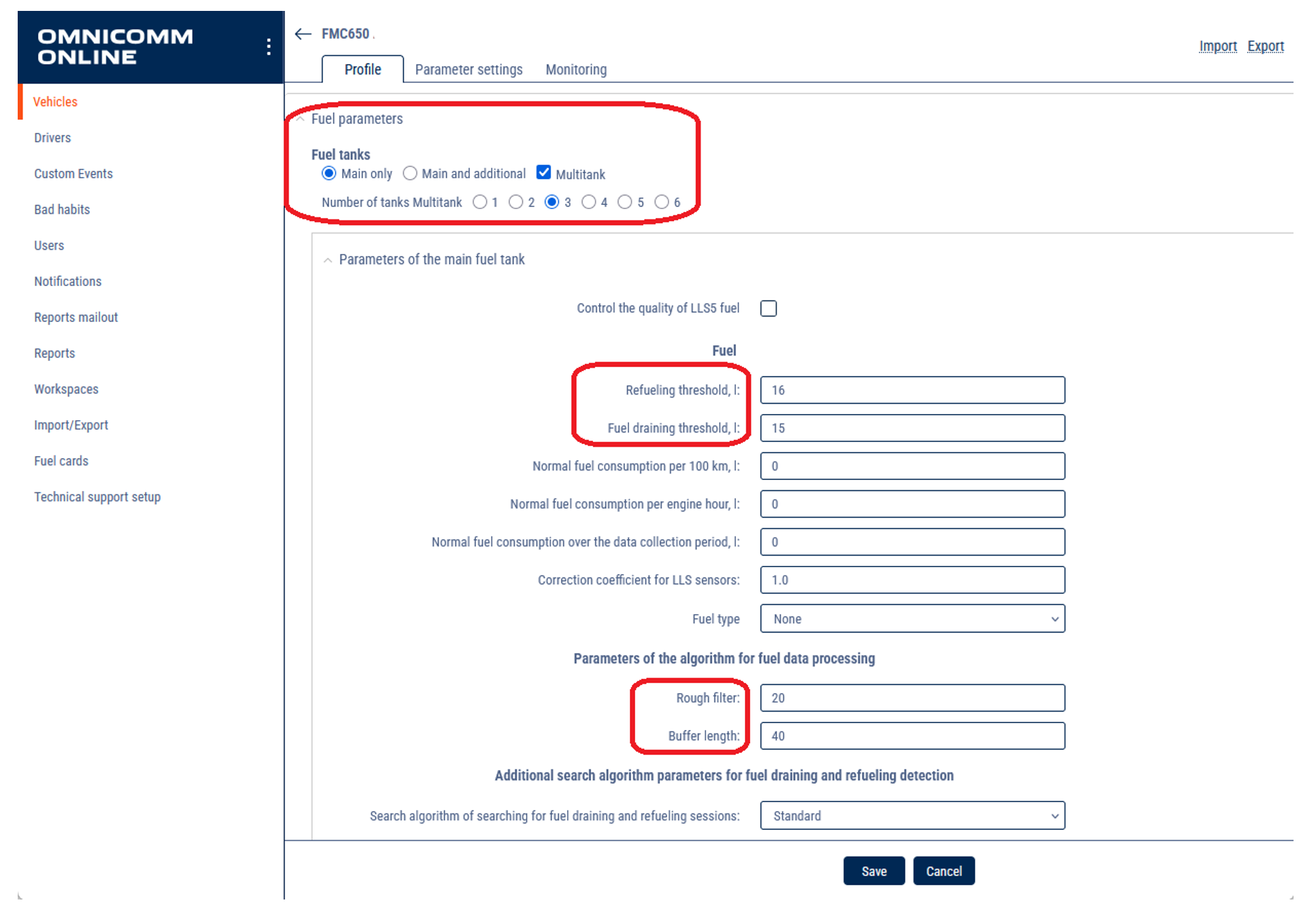

- In the Fuel parameters section, choose a number of tanks and number of installed LLS.

“Fuel tanks” - Select the number of fuel tanks installed on a vehicle:

- Main only means only one fuel tank is installed on a vehicle - Main and additional means two fuel tanks are installed on a vehicle. For refuellers, the main tank is the reservoir, the additional tank is the engine fuel tank. For the vehicle, the main tank is the engine fuel tank, the additional tank is the fuel tank for the optional equipment. - Multitank means up to 6 fuel tanks are installed on a vehicle. Available to users with established rights to objects: Access to Multitank (see Adding and editing a user profile).

Examples:

- Main tank and single sensor: Common scenario. - Main tank and 2 sensors and more: In case of a complicated shape or impossibility to install a sensor in the center, two or more sensors are used for measurement level in a single tank. - Main and additional tank and 2 sensors: A Vehicle has 2 tanks, and each tank is equipped with 1 sensor. - Main and additional tank and 3 or more sensors: A Vehicle has 2 tanks, and each tank is equipped with 1 or more sensors. - Main tank + Multitank or Main and additional tank + Multitank is scenarios for fuel bowser, gas stations e.t.c. For each cistern or isolated compartment could be assigned one or several sensors.

For each tank set up * Parameters of the fuel tank:

- Set up Refueling threshold (recommended value 7% of tank volume, number depends on condition);

- Set up Fuel draining threshold (recommended value 7% of tank volume, number depends on condition);

- Set up Rough filter (depends on road condition);

- Set up Buffer length (depends on road condition);

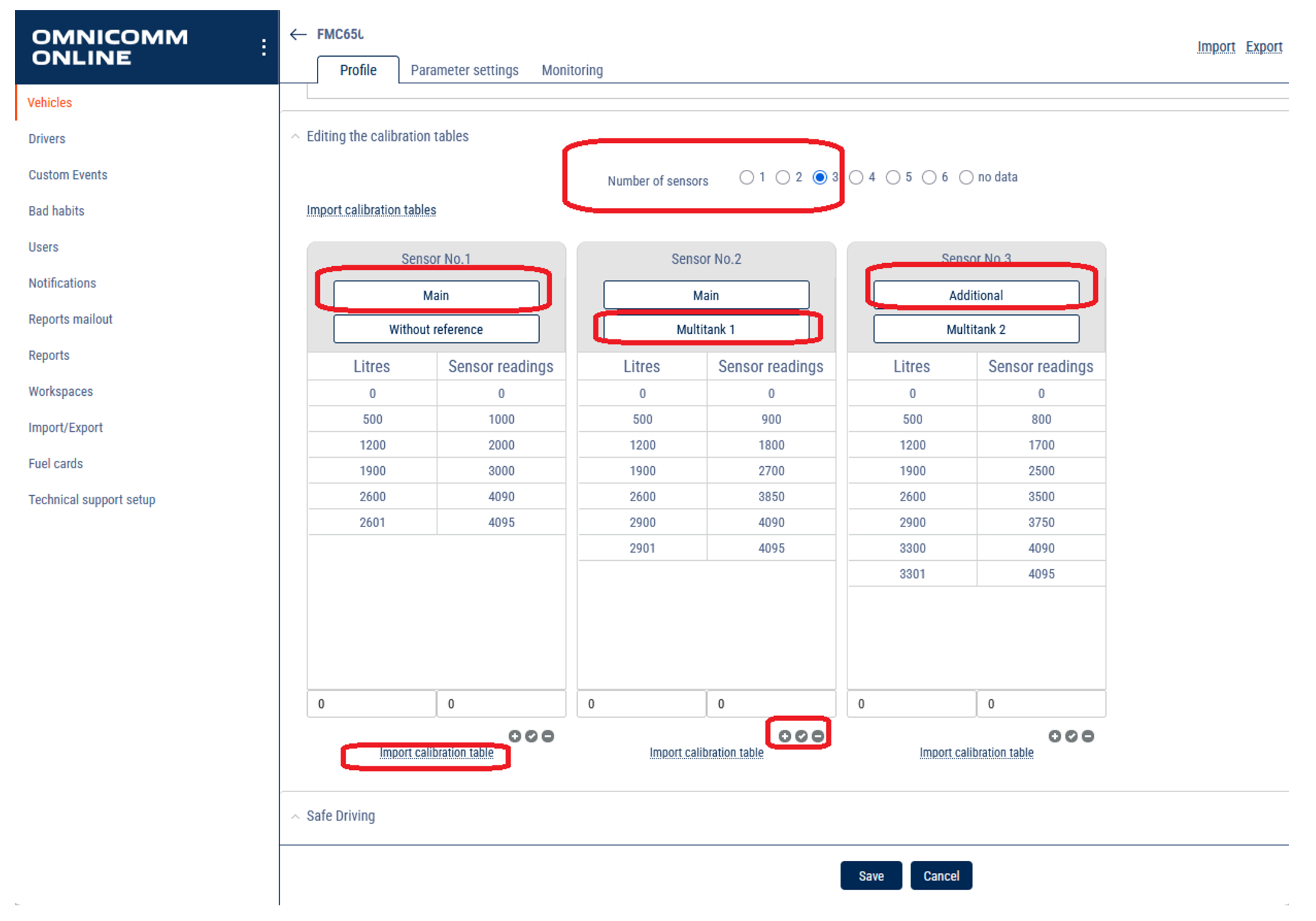

- In Editing the calibration tables, Import calibration tables or fill it manually and link sensors to the tanks.

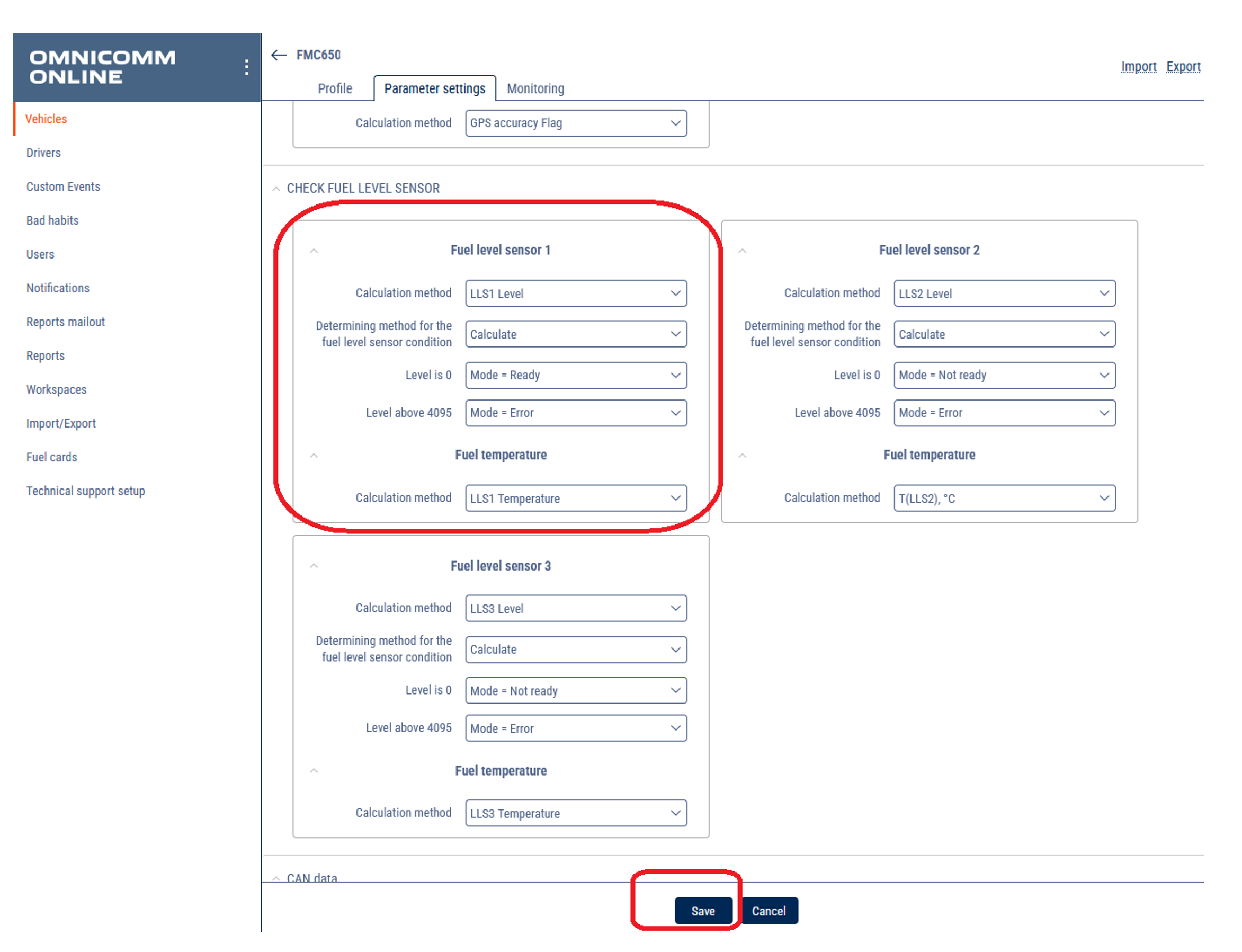

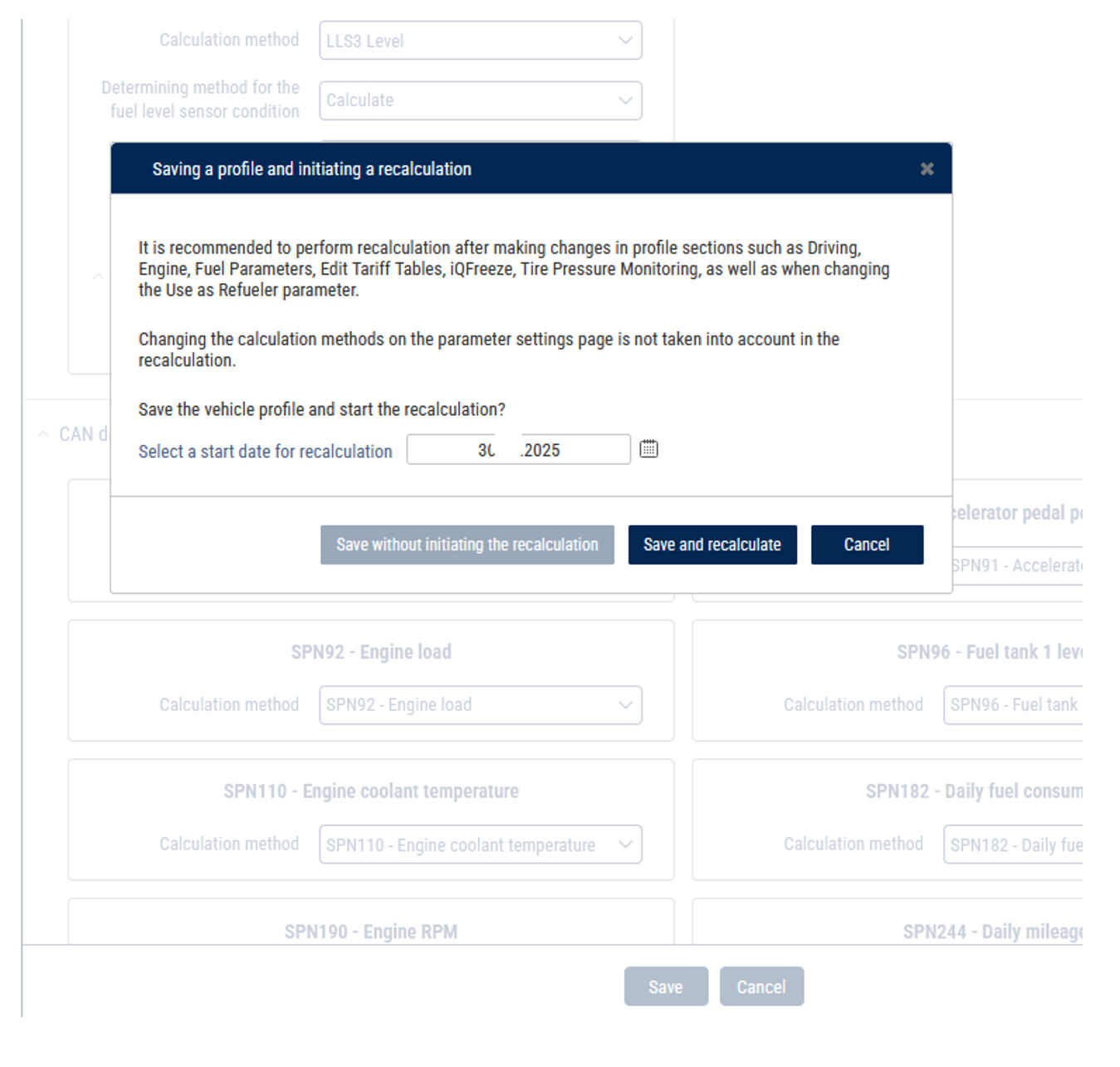

Open Parameter settings tab:

- Choose and link the necessary parameters.

For System flags:

- Choose GSM connection availability: Always-On connection.

For Navigation data:

- Choose GPS data accuracy: Number of visible GPS satellites.

- For CHECK FUEL LEVEL SENSOR choose the source of data for each LLS:

For Fuel level sensor 1:

- Calculation method: LLS1 Level

- Determining method for the fuel level sensor condition: Calculate

- Level is 0: Mode = Ready

- Level above 4095: Mode = Error

- Fuel temperature Calculation method: LLS1 Temperature

For Fuel level sensor 2:

- Calculation method: LLS2 Level

- Determining method for the fuel level sensor condition: Calculate

- Level is 0: Mode = Ready

- Level above 4095: Mode = Error

- Fuel temperature Calculation method: LLS2 Temperature

Same for each sensor.

- Click Save and recalculate.

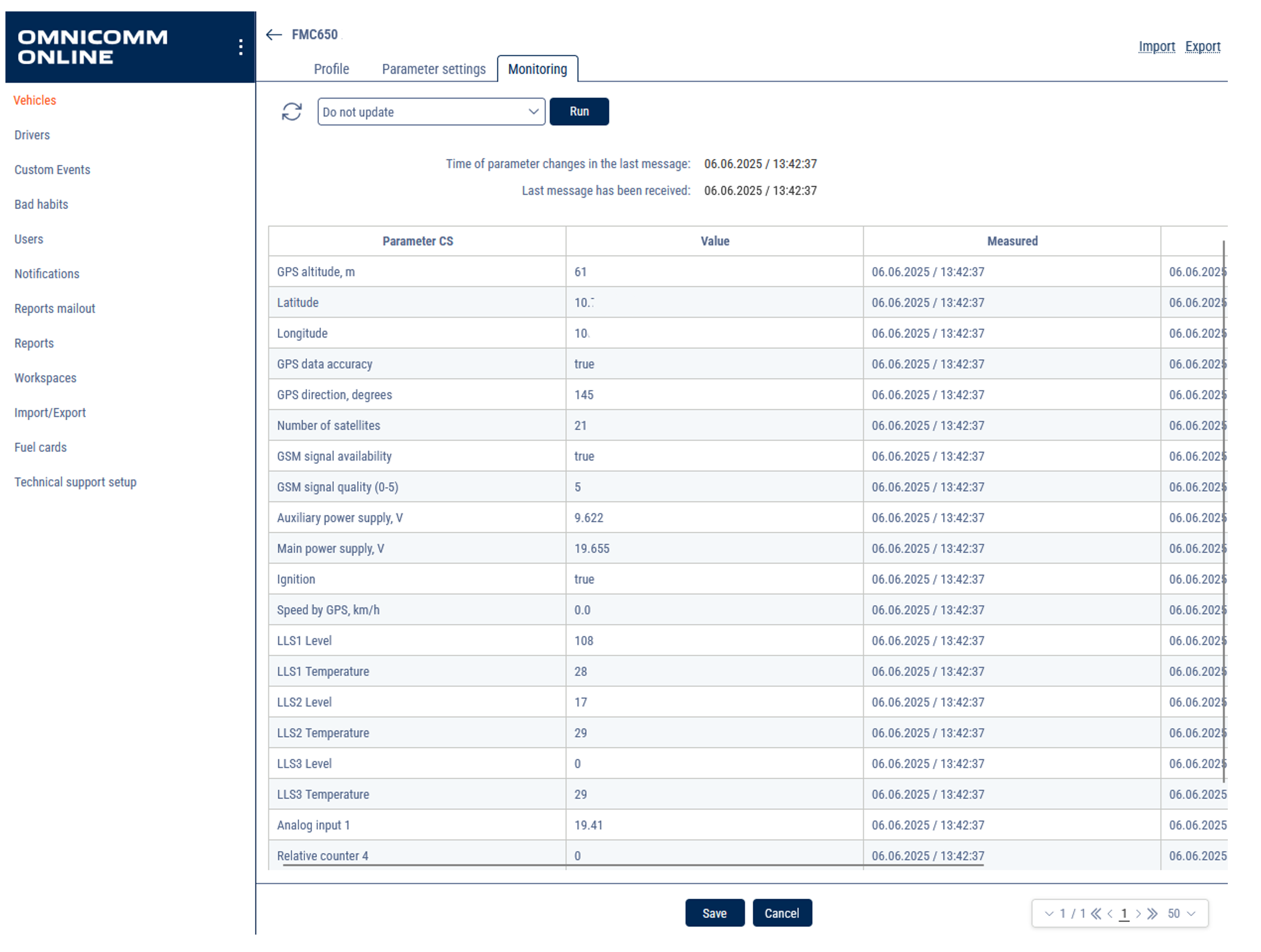

Choose VH in the list and click VH Profile button.

- Open Monitoring tab: check the received values.

Xirgo LX45

LX45 is a device with GNSS and Cellular connectivity, designed for object tracking. It can acquire information on object location, speed, direction, etc., and transfer the data via a Cellular network. Digital and analog inputs of the device may be used to connect different external sensors/devices. Outputs of the device may be used to control external equipment remotely. Flexible configuration allows users/dealers to adjust the device to meet their specific requirements. All device settings and firmware are updated remotely via GPRS. It is possible to create setting templates for groups of vehicles, use mass updates and create unique device operation logic, fulfilling the requirements of most cases on the market.

Device Installation

Device installation (LX45)

Central unit is only mounted in inside of the vehicle, it can not be installed in the engine chamber, next to the cabin, or in the area of exposure to direct external conditions. Central unit must be hidden (for example, under the upholstery), as well as protected from moisture exposure. Device must be fastened in a stable position to avoid random twitches and displacements (suspension on cables is strictly prohibited). Central unit must be mounted horizontally. Precise orientation is of particular importance to flawless operation of the system, since the device is equipped with acceleration sensors recording the data which directly affects the results obtained.

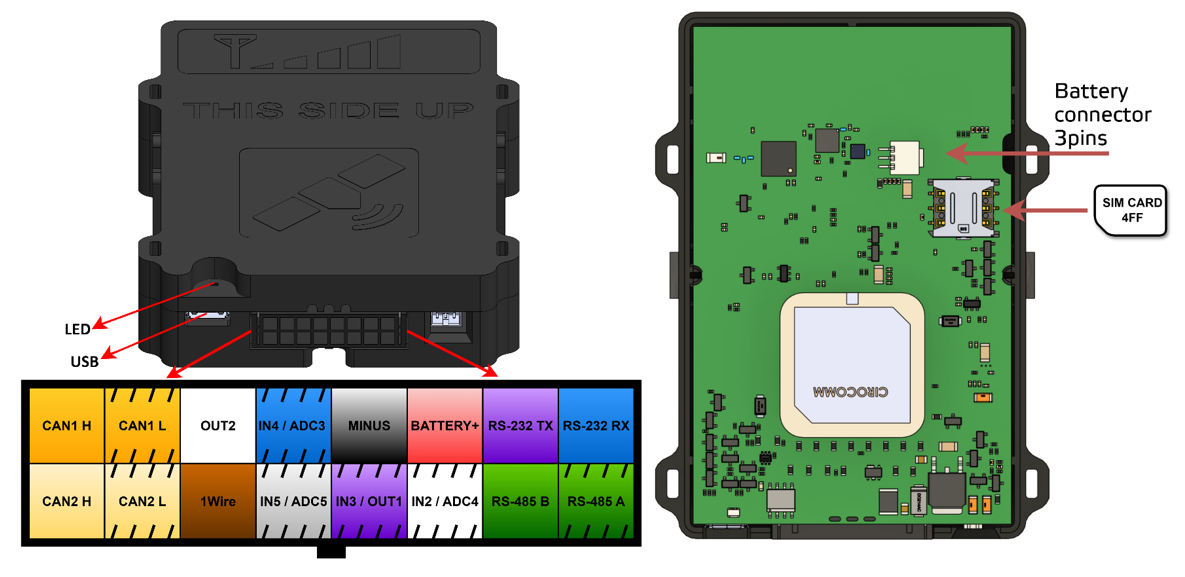

LX45 pinout

To insert a SIM card, connect the internal battery open the box by lifting plastic holders from both sides.

Power supply

Power supply of central unit has to be connected directly from the vehicle’s battery, using 3A fuse.

Ground wire

Ground wire should be connected to the vehicle body. A reliable electrical contact with the body must be ensured, wire has to be bolted.

Ignition input (combustion lock status)

Connect a wire of the vehicle where voltage is present only when ignition is activated to IN5.

Universal digital inputs (optional)

Universal Digital inputs (IN2; IN3; IN4; IN5) are intended to collect data from remote devices.

Analog inputs (optional)

Analog inputs are intended to collect data from remote devices by measuring voltage. ADC3, ADC4, range 0-31V.

RS232 TX & RS232 RX

Minimum voltage: -15V

Maximum voltage: +15V

EIA 485 A & EIA 485B

Minimum voltage: -7V

Maximum voltage: +12V

Steps to install the central unit:

- Open the housing by gently lifting the plastic holders on each side and remove the PCB from it. o Use thin screwdriver to lift up the plastic holders in order not to brake them.

- Locate the SIM holder and following the printed picture on the PCB insert the SIM card.

- Place the PCB to the housing and close it.

- Use plastic fastening straps to fix device in a stable position (units housing has four holes, for straps to go through and fasten them to the body of the vehicle).

- Connect power supply;

- Connect ignition wire to a digital input (usually IN5);

- Connect array;

- Connect fuel level sensor(s) to the RS-232 or RS-485 interface;

- To read FLS sensor based on RS232, calibrate your sensor and connect to the device using Blue and Purple wires on device side.

Note, that RX of device goes to TX of sensor, as well as TX goes to RX. At once, can be connected only one RS232 based device with baud rate of 19200 bps.

- To read FLS sensor based on RS485, calibrate your sensor and connect to the device using Green and Green/black wires on device side.

Note, that A of device goes to A of sensor, as well as B goes to B. At once, can be connected up to 14 RS485 based devices. Connection should be made in parallel way, also should be set different addresses while calibrating FLS. Baud rate must be set to 19200 bps.

9. Connect other devices (optional).

Configuration

LX45 is to be configured via a configuration server, where dealers/users can adjust the operation of their devices to fulfill specific requirements.

However, if you encounter difficulties while installing or using this product, technical support is available and may be reached by e-mail [email protected] or [email protected].

1. To configure the tracker, you must have an account from the Xirgo support team to the remote configuration platform : https://xdm.xgfleet.eu/login.

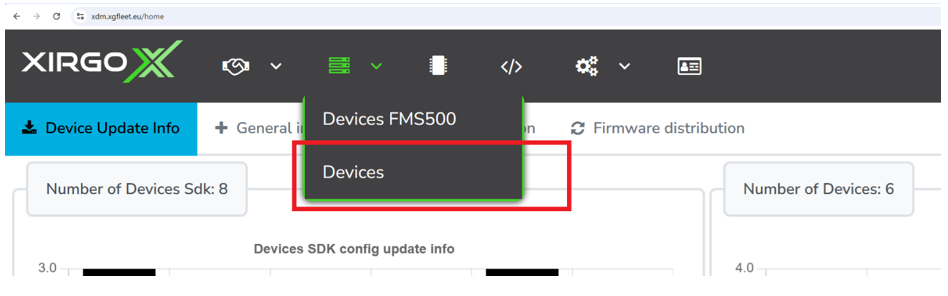

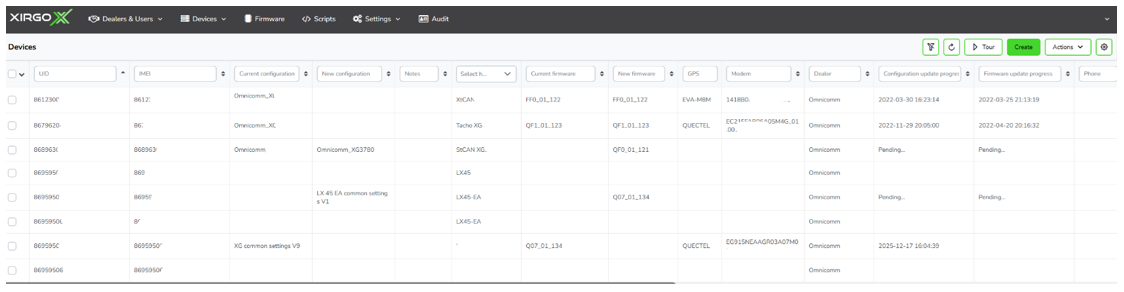

2. Go to the devices section and ensure that the configured device is in the list.

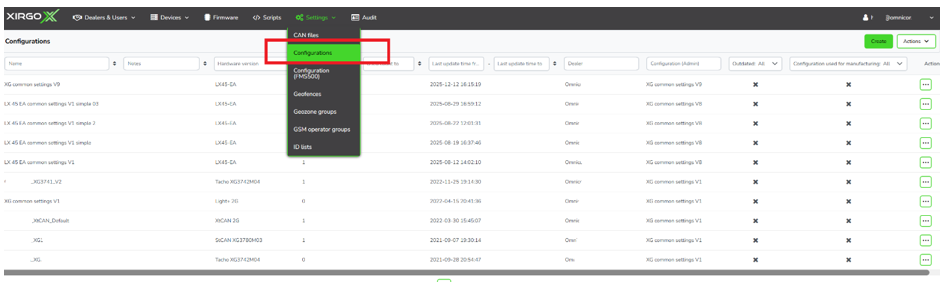

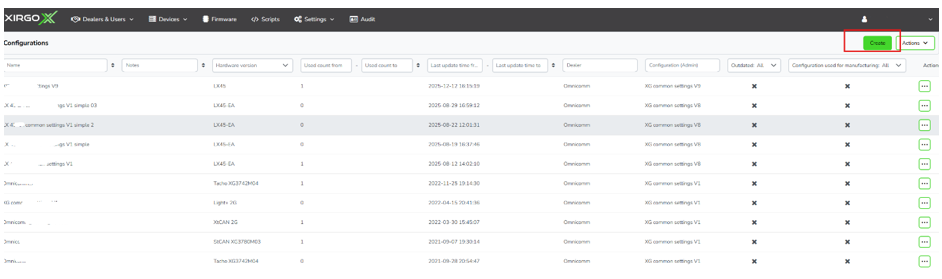

3. Go to the configuration section and find the available configuration in the list or create a new configuration.

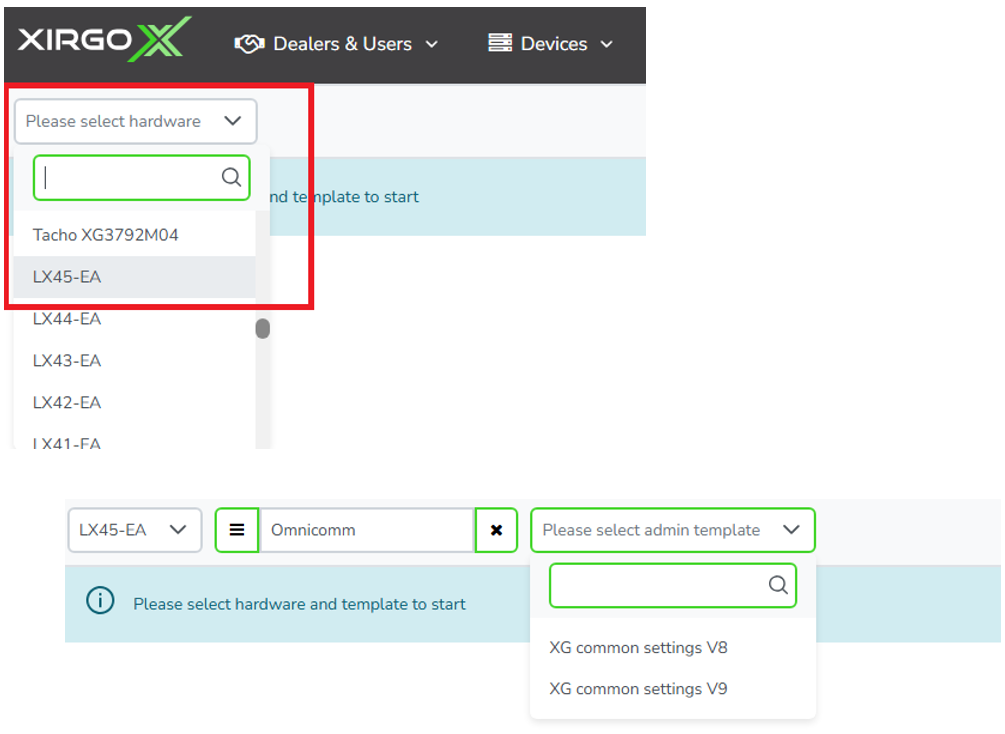

4. Click on new template creation button.

5. Then step by step choose Device type, then Dealer to which you want to assign template, then admin template on which you will build new template:

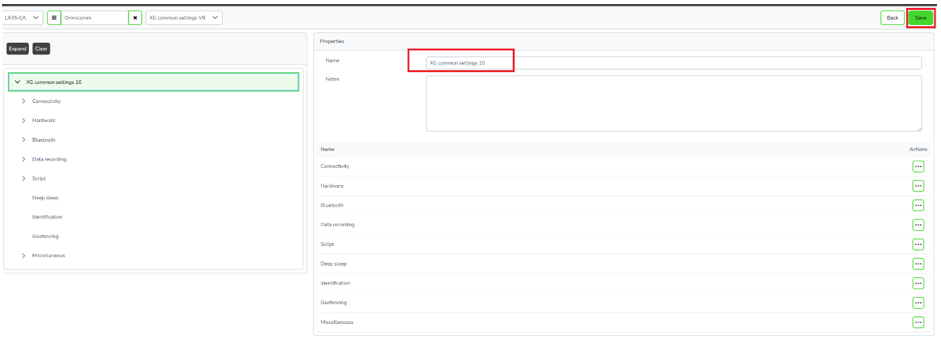

Mandatory Set Up Within Setting Template

There are three fields, which are most necessary to be able to receive data on the platform:

- Name;

- Connectivity > Telemetry server > MQTT broker address;

- Connectivity > GSM/GPRS > APN list;

- Data recording > Simple.

a) Name.

Set an understandable name and add notes.

b) Set address where to send data.

All data will be sent to broker, so set address and port where data should be sent:

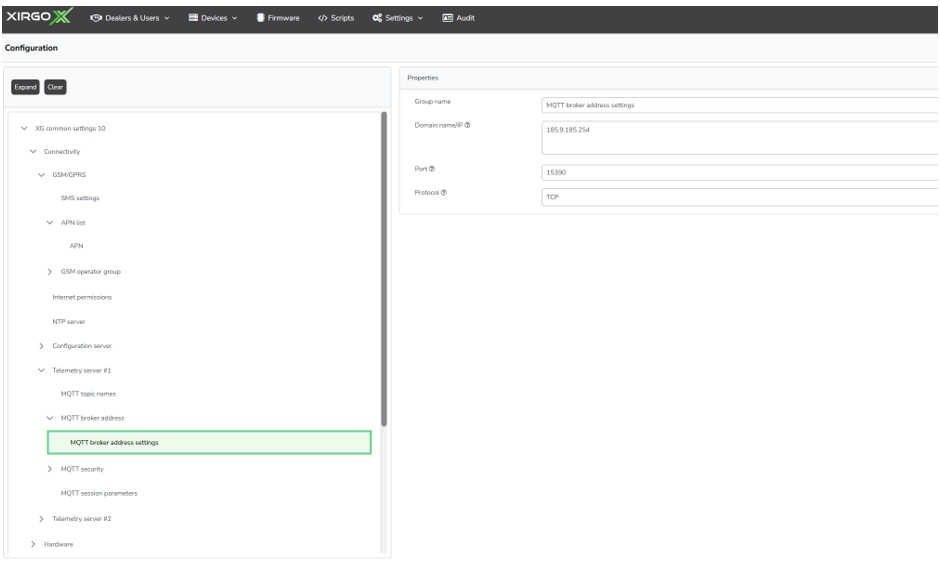

Device settings\Connectivity\Telemetry server #1\MQTT broker address\MQTT broker address settings:

For https://online.omnicomm.ltd/ (For other domain please contact Omnnicomm technical support):

- Domain name/IP : 185.9.185.254 or convert.omnicomm.ru

- Port : 15390

- Protocol : TCP

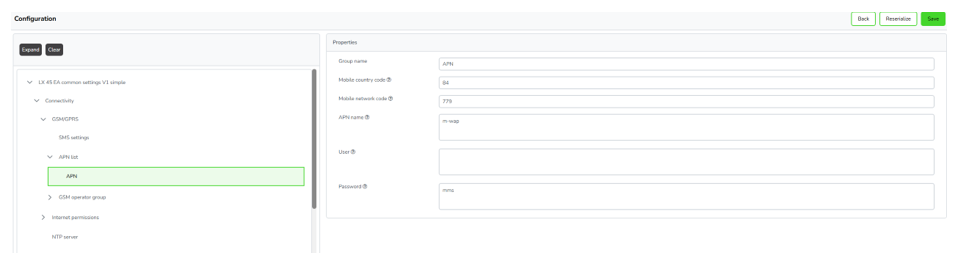

c) Set APN of SIM inserted to device.

Device settings\Connectivity\GSM/GPRS\ APN list\ APN:

To configure you would need to know MCC, MNC and APN of SIM.

Note. MCC, MNC are five first digits of IMSI code (123 - MCC, 45 - MNC).

If you use few different operators, can insert all of them, but mandatory is the one of SIM, inserted to device.

Set:

- Mobile country code

- Mobile network code

- APN name

- User

- Password

d) Set which data should be sent to send to the platform.

“Data recording” is responsible for structure of data, that being sent to MQTT broker.

It supports two methods of data structure - Simple and Extended.

In “Simple” - you can create packets, in “Extended” you can create separate sensors and set conditions and triggers to them. Meanwhile in “Simple” triggers can be set only to all packet, not separate sensors.

“Simple” - is recommended way to send data.

”Extended” - can be used in specific projects, when you need to track values of particular sensor, for example: temperatures, RPM, over-voltages or similar.

Note. Simple and Extended options can not be used simultaneously. If you set both - device would not send any data.

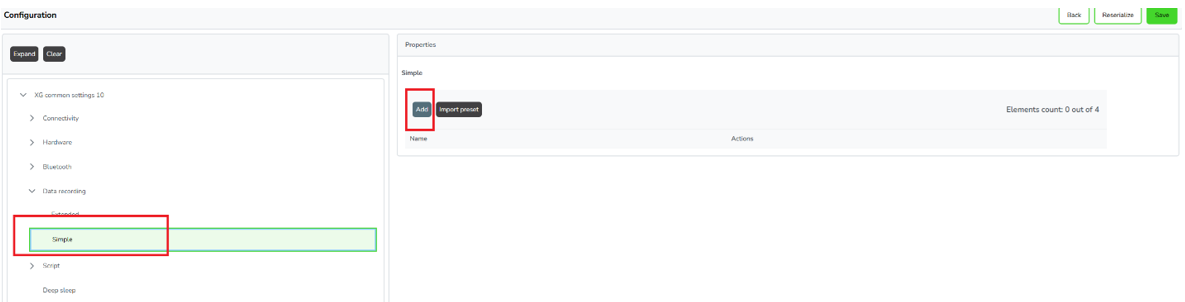

Device settings\ Data recording\Simple\ APN list\ APN:

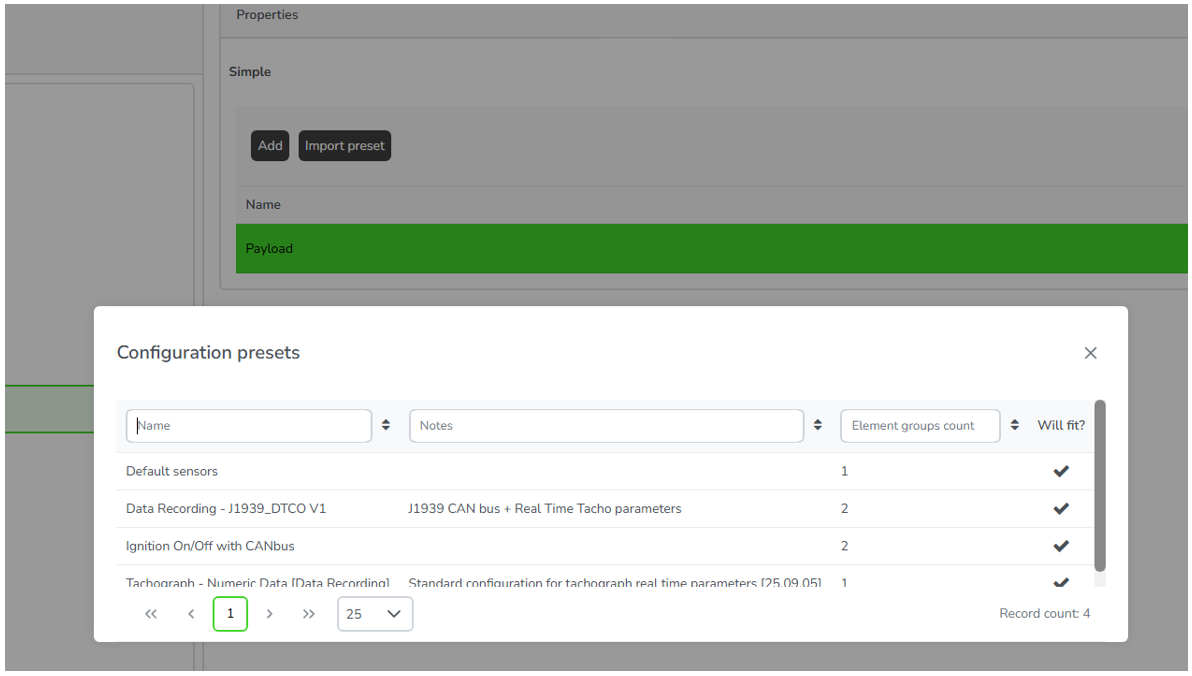

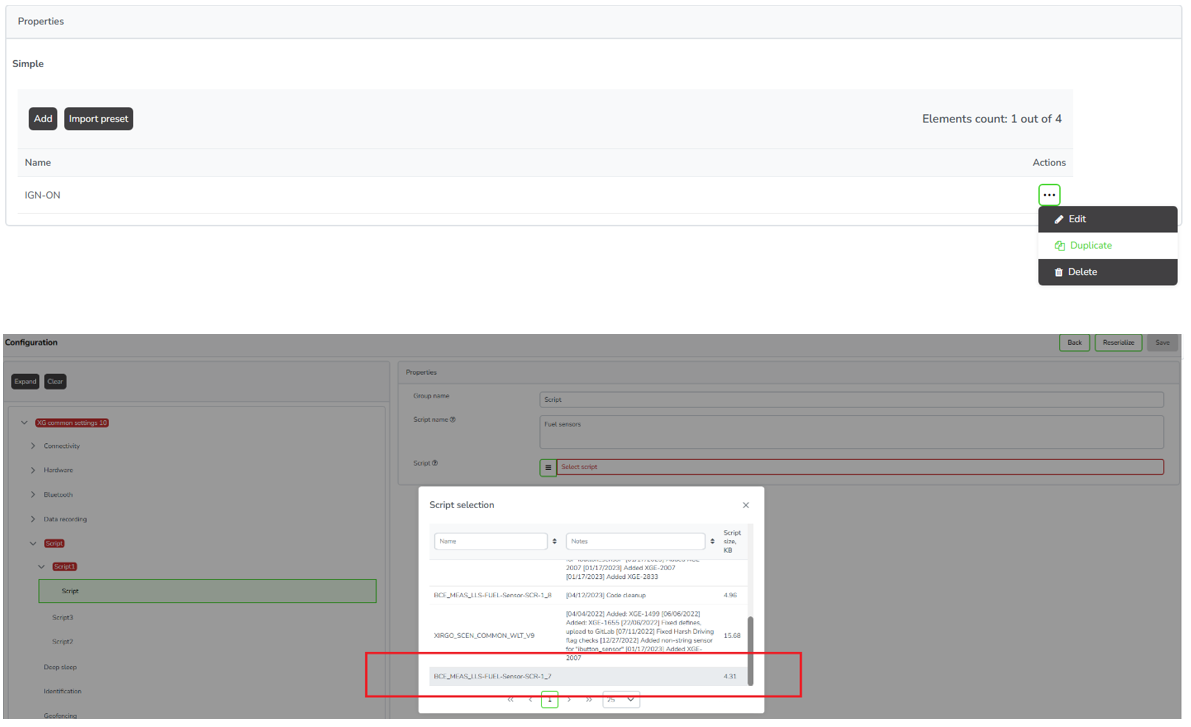

In ‘Data recording’ click on “Simple” and then “+ Add” button to create a packet, which will be sent to server.

Also, you can use button of “Import preset” and choose preset based on type of device, for example:

Simple data sending method.

You can create 4 different packets based on different conditions. To create a new packet, click on “+ Add” button. Also can check presets, created by XG team by clicking on “Import preset” button.

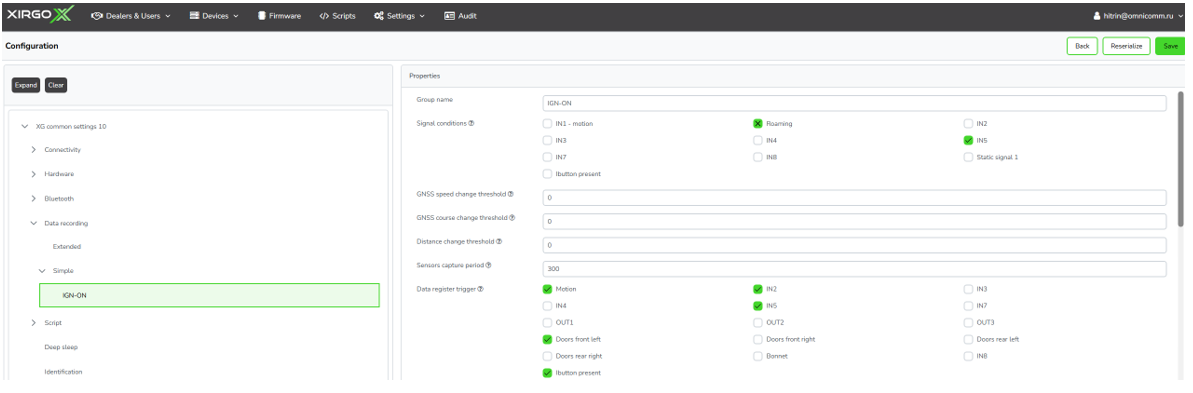

Signal conditions describes when this type of packet should be sent:

Speed, course, distance and time thresholds defines track quality settings.

Note. “GNSS register period” is responsible to how often device will send this kind of packet to server.

In “data register trigger” you can add additional triggers to send a message to server without waiting for “GNSS register period” to pass:

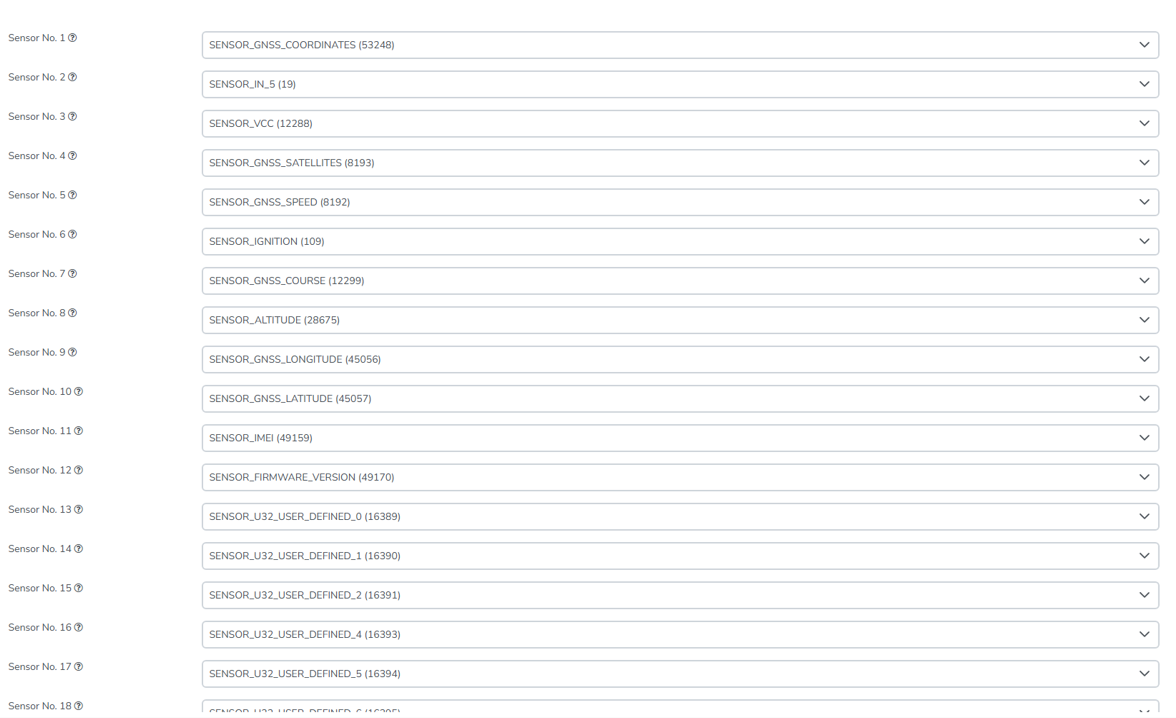

Into sensor list, you should add all sensors, which packet should include:

Recommended sensors:

- SENSOR_GNSS_COORDINATES (53248)

- SENSOR_ISOBUS_IMPLEMENT_1 (61432)

- SENSOR_GNSS_SPEED (8192)

- SENSOR_GNSS_COURSE (12299)

- SENSOR_AXES_X (28672)

- SENSOR_AXES_Y (28673)

- SENSOR_AXES_Z (28674)

- SENSOR_ALTITUDE (28675)

- SENSOR_GNSS_SATELLITES (8193)

- SENSOR_GNSS_LONGITUDE (45056)

- SENSOR_GNSS_LATITUDE (45057)

- SENSOR_IMEI (49159)

- SENSOR_FIRMWARE_VERSION (49170)

- SENSOR_VCC (12288)

- SENSOR_IGNITION (109)

- SENSOR_IN_2 (16)

- SENSOR_IN_3 (17)

- SENSOR_IN_4 (18)

- SENSOR_IN_5 (19)

- SENSOR_U32_USER_DEFINED_0 (16389)

- SENSOR_U32_USER_DEFINED_1 (16390)

- SENSOR_U32_USER_DEFINED_2 (16391)

- SENSOR_U32_USER_DEFINED_3 (16392)

- SENSOR_U32_USER_DEFINED_4 (16393)

- SENSOR_U32_USER_DEFINED_5 (16394)

You can adjust the list of sensors for your case.

Note. Parameters must be supported from Omnicomm Online side, do not put uncollected data in the list.

You can duplicate a list of parameters for various conditions and exclude/include parameters (parking, movement, etc.)

Script settings

Scripts will allow user to implement various scenarios and control device peripherals.

Script is a program (programming code), written in C like language.

We recommend using script templates to avoid errors in functionality.

Device settings\ Script\Script

Click Add script and choose the necessary template (example Script LLS-FUEL-Sensor-1-7).

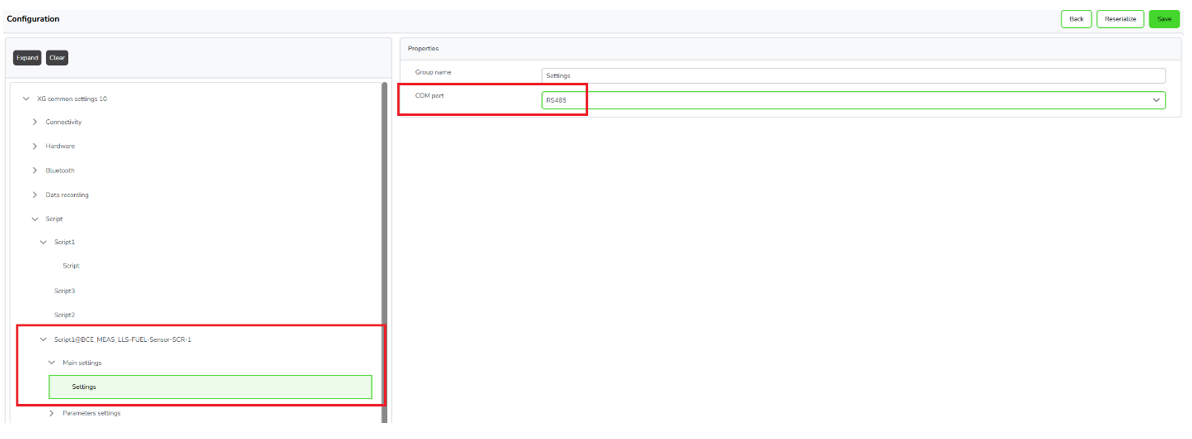

Go to the script settings: Device settings\ Script\ Your script (Script1@BCE_MEAS_LLS-FUEL-Sensor-SCR-1)\Main settings\ Settings.

Choose a Port for the sensors' connection (RS-232 or RS-485).

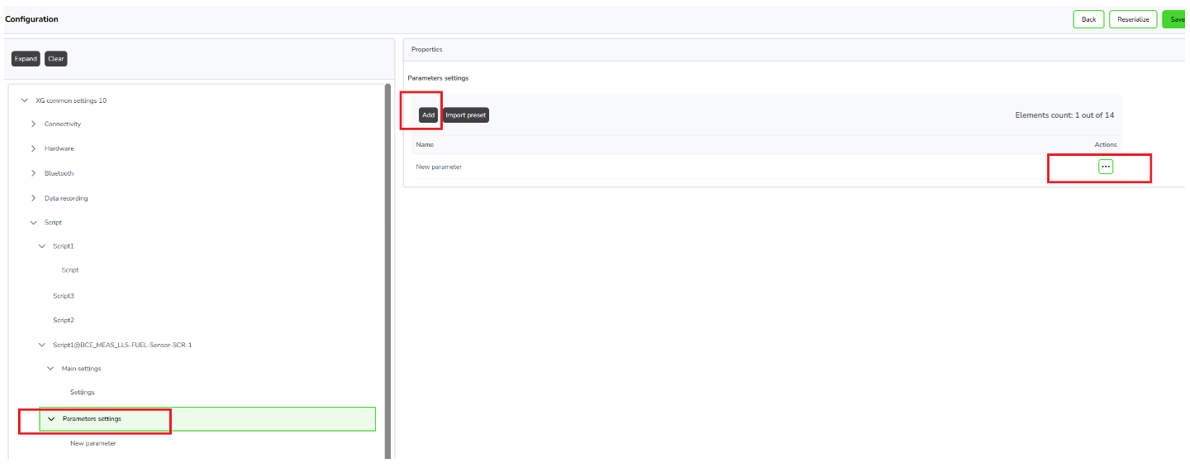

Go to Device settings\ Script\ Your script (Script1@BCE_MEAS_LLS-FUEL-Sensor-SCR-1)\Main settings\Parameters settings\.

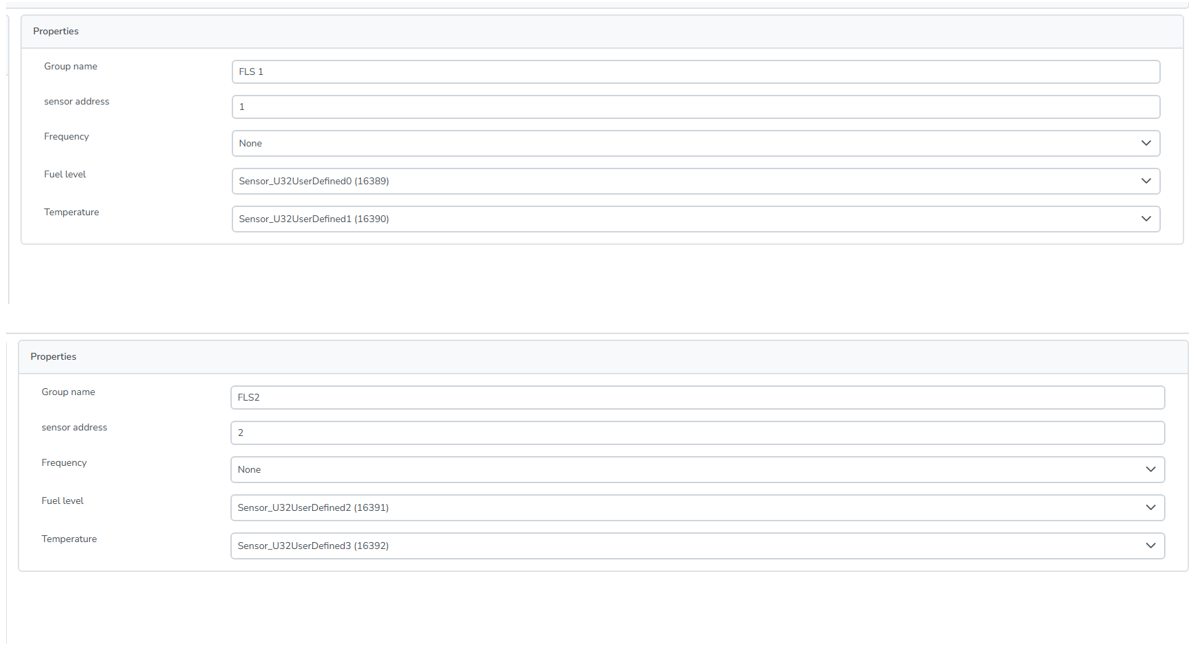

Add the necessary quantity of parameters(for each sensor) and edit it:

Change parameter name, address and choose data and position in the message(same in data collection section)

For fuel sensors level supported parameters are: Sensor_U16UserDefined2-15.

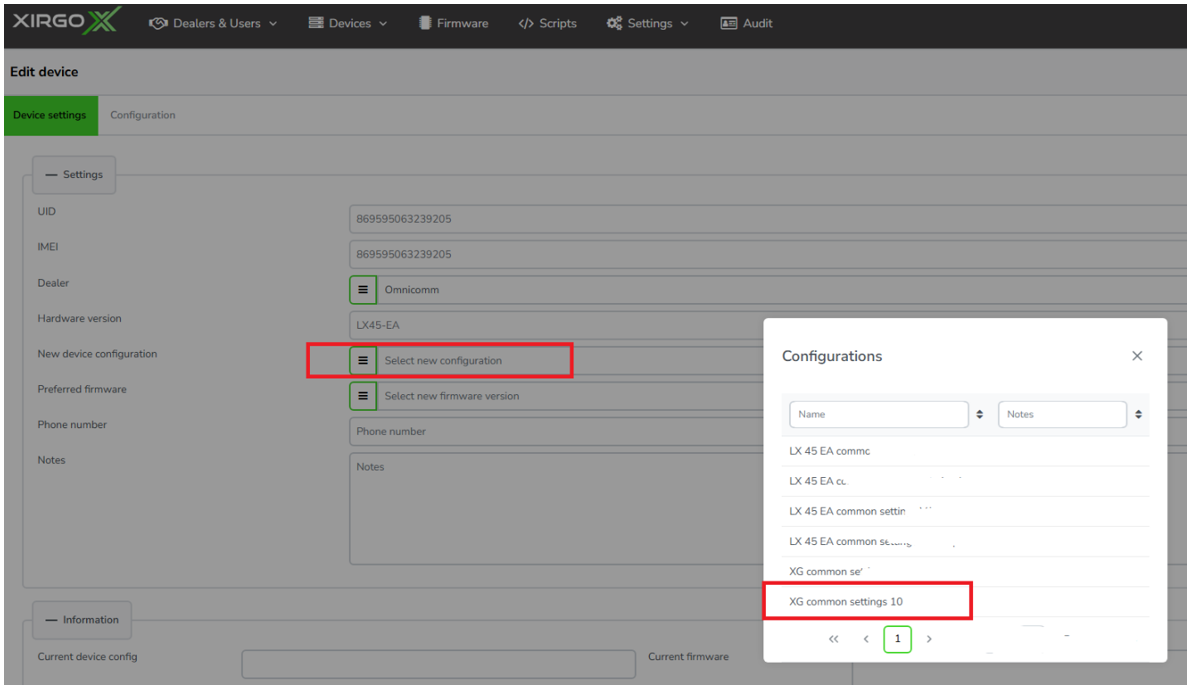

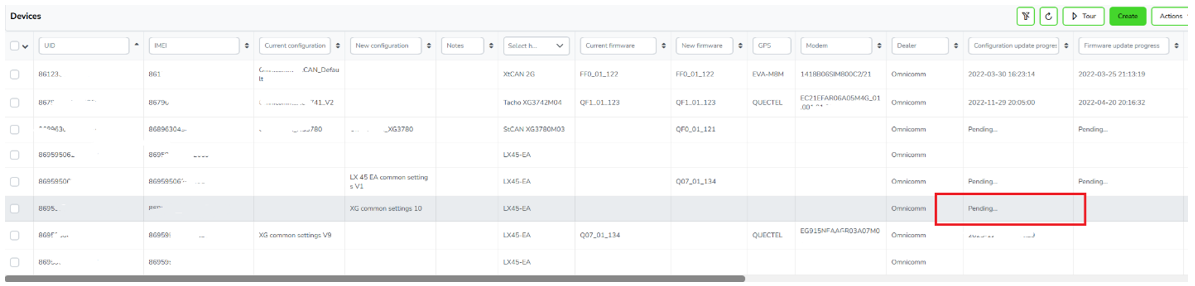

Save the configuration and go to the devices section. Click on your device and choose configuration from the list.

You have to wait until it is uploaded to the device through the remote server.

The second option to download the configuration with USB.

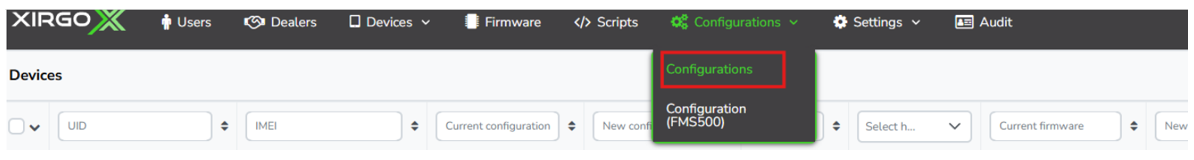

Step 1: Click Configurations icon in the main menu bar. The devices page appears.

List of all configurations created will appear in your screen.

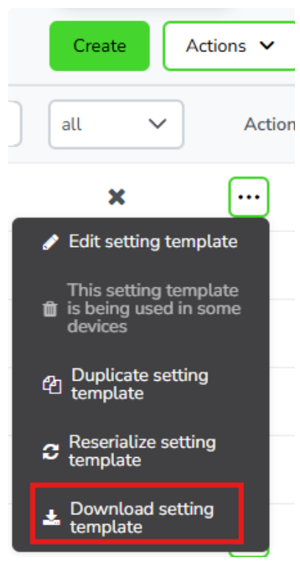

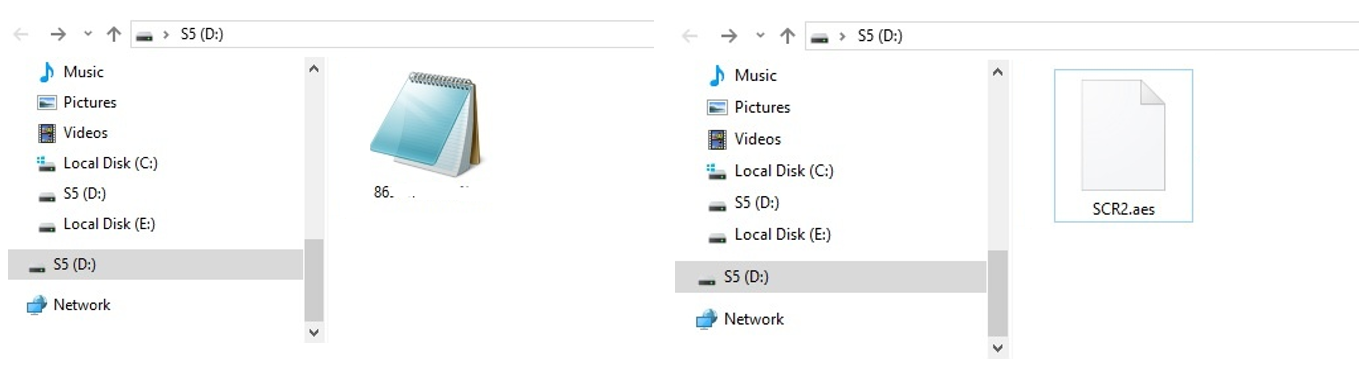

Step 2: In the Actions menu click on the download icon to get the binary configuration file.

II. Firmware Download.

Step 3: Click Firmwares icon in the main menu bar. All available and assigned firmwares will appear.

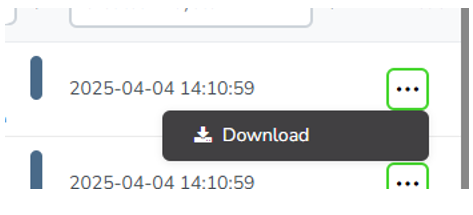

Step 4: Click on download icon to get the firmware .aes file.

III. Uploading files to device.

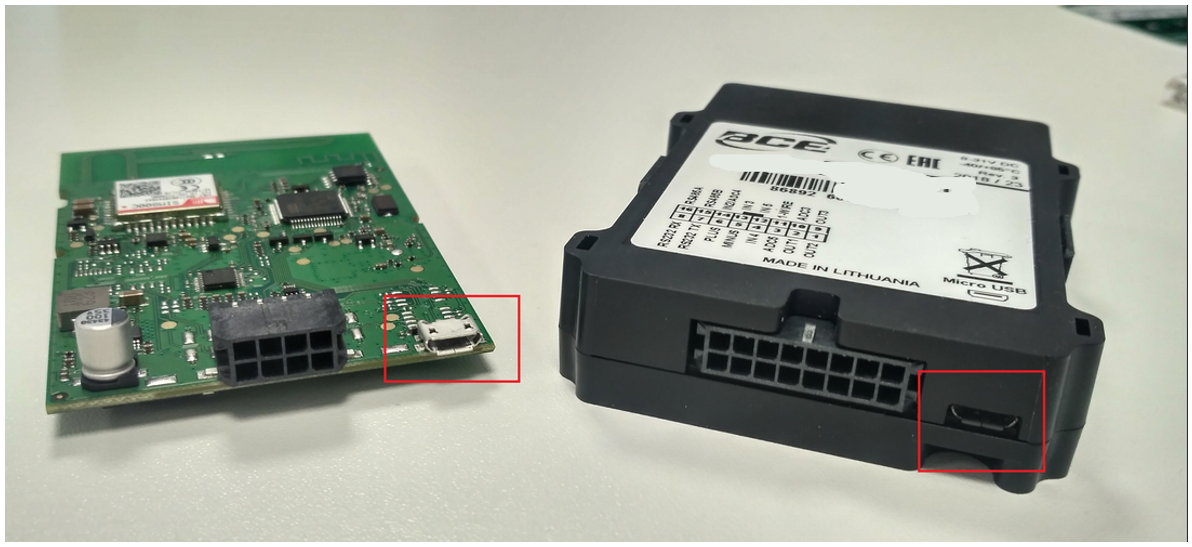

Step 5: Connect device to a PC.

Note. Device must be disconnected from any power source (internal battery as well). Using USB – mini USB cable connect device to a computer.

Step 6: New flash drive will appear. In some cases you might need to format the flash, before uploading the file.

Step 7: Copy/paste the configuration file or the firmware file to the flash drive.

Note: Insert only one file at once. If you need to update both -FW & settings, do it separately. After uploading one file, connect device to the power, then disconnect and upload another file.

Step 8: Disconnect the USB cable and power up the device. It should take a couple of seconds for the device to boot up and flash the new settings or FW.

To add a device to the platform, you can follow https://doc.omnicomm.ltd/en/omnicomm_online-administration/vehicle/add

Fuel sensors settings parameter settings tab:

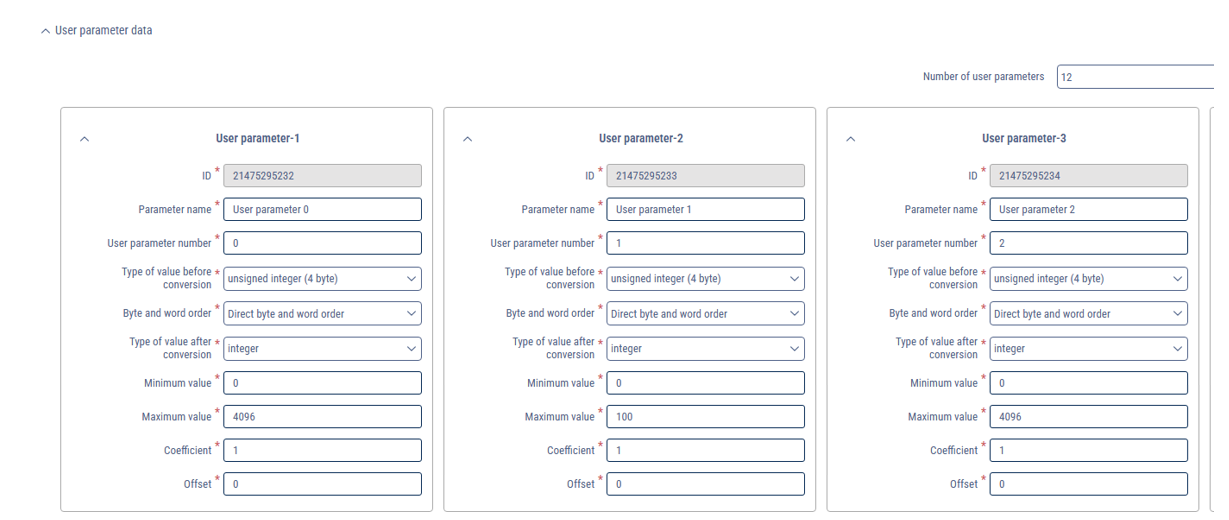

To receive fuel data, you need to configure user settings in the profile settings section.

https://doc.omnicomm.ltd/en/omnicomm_online-administration/vehicle/add/setparametrs/table

Open Parameter settings tab:

We recommend the following values for obtaining fuel user parameters:

- User parameter number: 0, 2, 4, 6 -fuel level; 1, 3, 5, 7 -temperature;

- Type of value before conversion: unsigned integer (4 byte)

- Byte and word order: Direct byte and word order

- Type of value after conversion: integer

- Minimum value: 0

- Maximum value: 4046

- Coefficient: 1

- Offset: 0

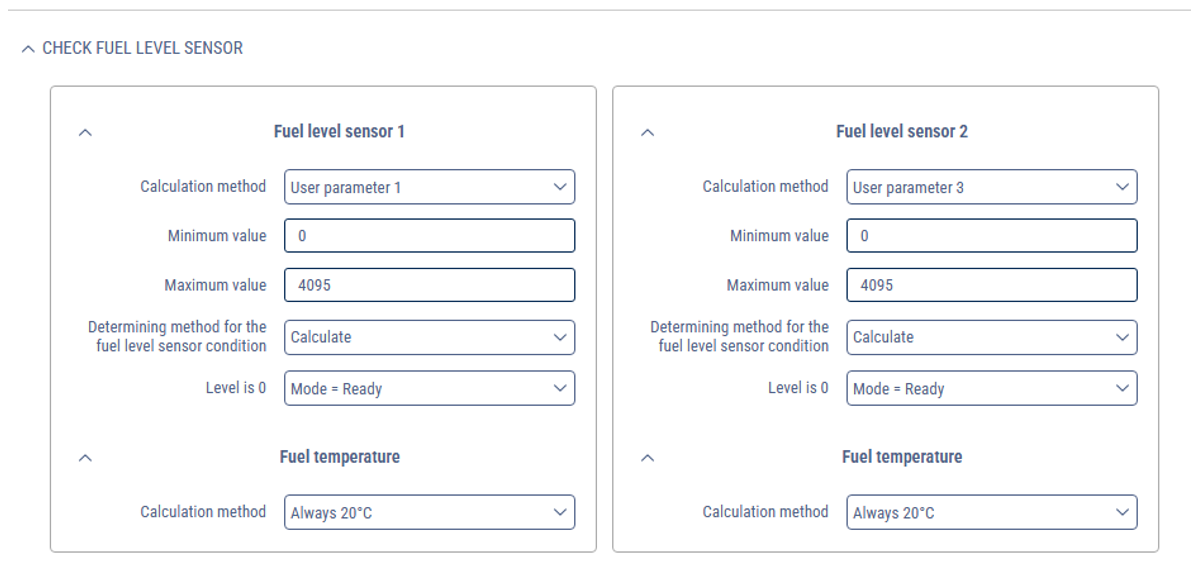

- For CHECK FUEL LEVEL SENSOR choose the source of data for each LLS:

For Fuel level sensor 1:

- Calculation method: User parameter 1, 3, 5, 7 etc

- Determining method for the fuel level sensor condition: Calculate

- Level is 0: Mode = Ready

- Level above 4095: Mode = Error

- Fuel temperature Calculation method: Always 20°C