Use Cases

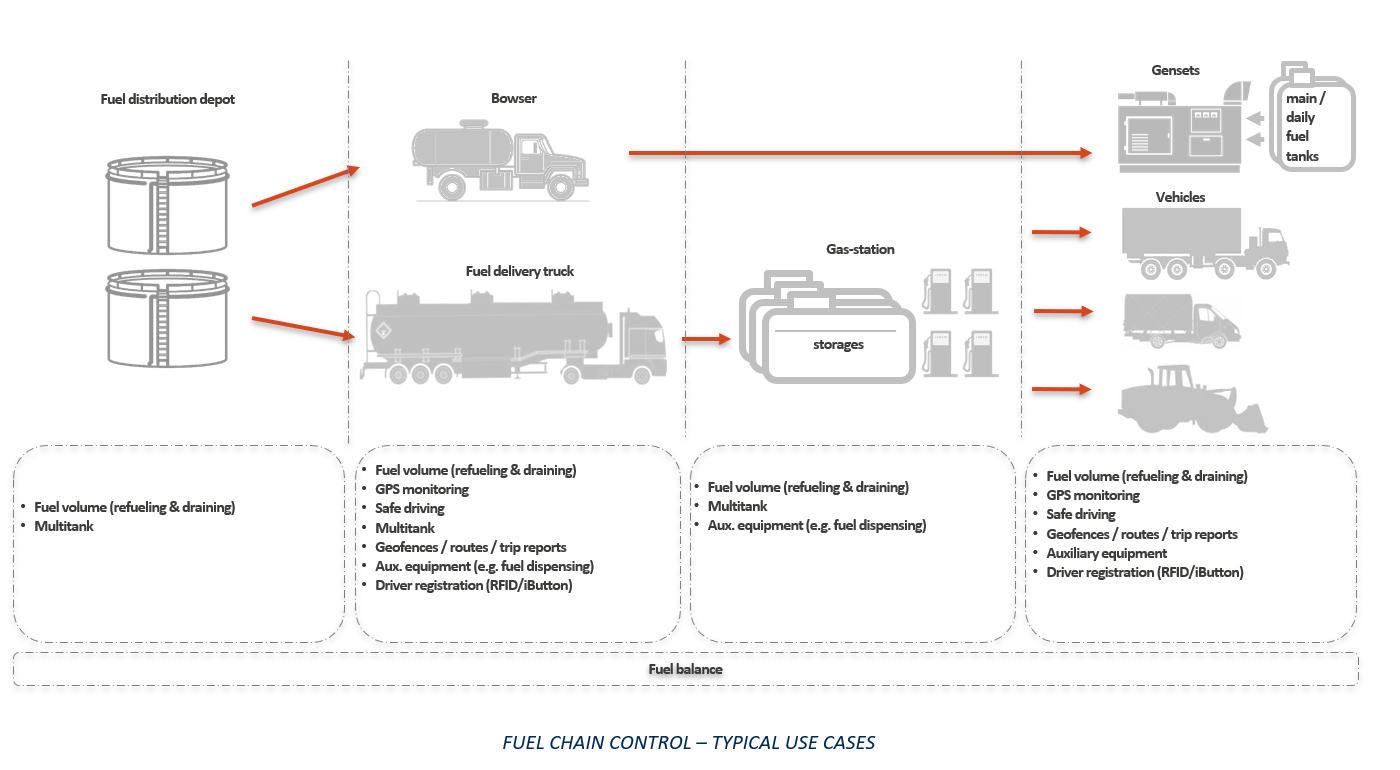

A typical fuel delivery chain from a distribution storage facility to end consumers may include several types of objects and vehicles. Omnicomm systems are designed to monitor and manage fuel at each stage of this chain.

For each type of facility in the monitoring system, there is a set of recommended reports most suitable for monitoring and operational efficiency.

Typical applications include fuel delivery to remote sites, mobile refueling of machinery, service trucks carrying supply fuel, construction and mining operations, and any fleet where fuel accountability, usage efficiency, and asset monitoring are critical. For mixed fleets and large companies, the solution scales easily — from a few tankers to dozens of vehicles, heavy machinery, and stationary storage.

For a single enterprise, with multiple objects equipped with Omnicomm devices, the most informative report is the Fuel Balance Report, which allows tracking and monitoring fuel flows across the entire company.

A sample set of reports and options specific to monitoring in various industries is shown below. These recommendations may vary depending on the customer’s specific requirements.

| Fuel storages | Bowsers and fuel delivery trucks | Gas-stations | Regular vehicles | Mining & construction | Generator sets | Locomotives | Maritime (boats, ships) | Agriculture | |

|---|---|---|---|---|---|---|---|---|---|

| Fuel Level report | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Fueling and Draining | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Fuel Dispensing | option | option | option | no | no | no | no | no | no |

| Fuel Balance | option | option | option | option | option | option | no | no | option |

| Multitank | yes | yes | yes | no | no | option | no | yes | no |

| Movement & GPS monitoring | no | yes | no | yes | yes | option (for rental) | yes | yes | yes |

| Geofences & routes | no | option | no | option | option | no | option | option | yes |

| CAN BUS readings | no | option | no | option | option | option | no | no | yes |

| Auxiliary equipment | option | option | option | option | yes | option | yes | yes | yes |

| RFID/iButton (authorization) | option | option | no | option | option | option | option | no | yes |

| Safe Driving | no | yes | no | yes | yes | no | yes | no | no |

| RPM | no | yes | no | yes | yes | yes | option | option | yes |

| ICON | option | yes | option | option | yes | option | yes | option | option |

| Special | LLS-EX 5 | LLS-EX 5, fuel balance | LLS-EX 5, fuel balance | fuel balance | Options: Port & Profi Wi-Fi, fuel balance | Options: genset utilization & overloads. Remote disabling | Special power converters | LLS-Ex 5 |

* - manipulators, opening control, axle load, status control, temperature, TPMS, IQFreeze, etc.

* * - an integral infrastructure of the fuel storage facilities, as well as mobile objects equipped with Omnicomm sensors and terminals (fuel trucks, mobile gas stations, etc.)

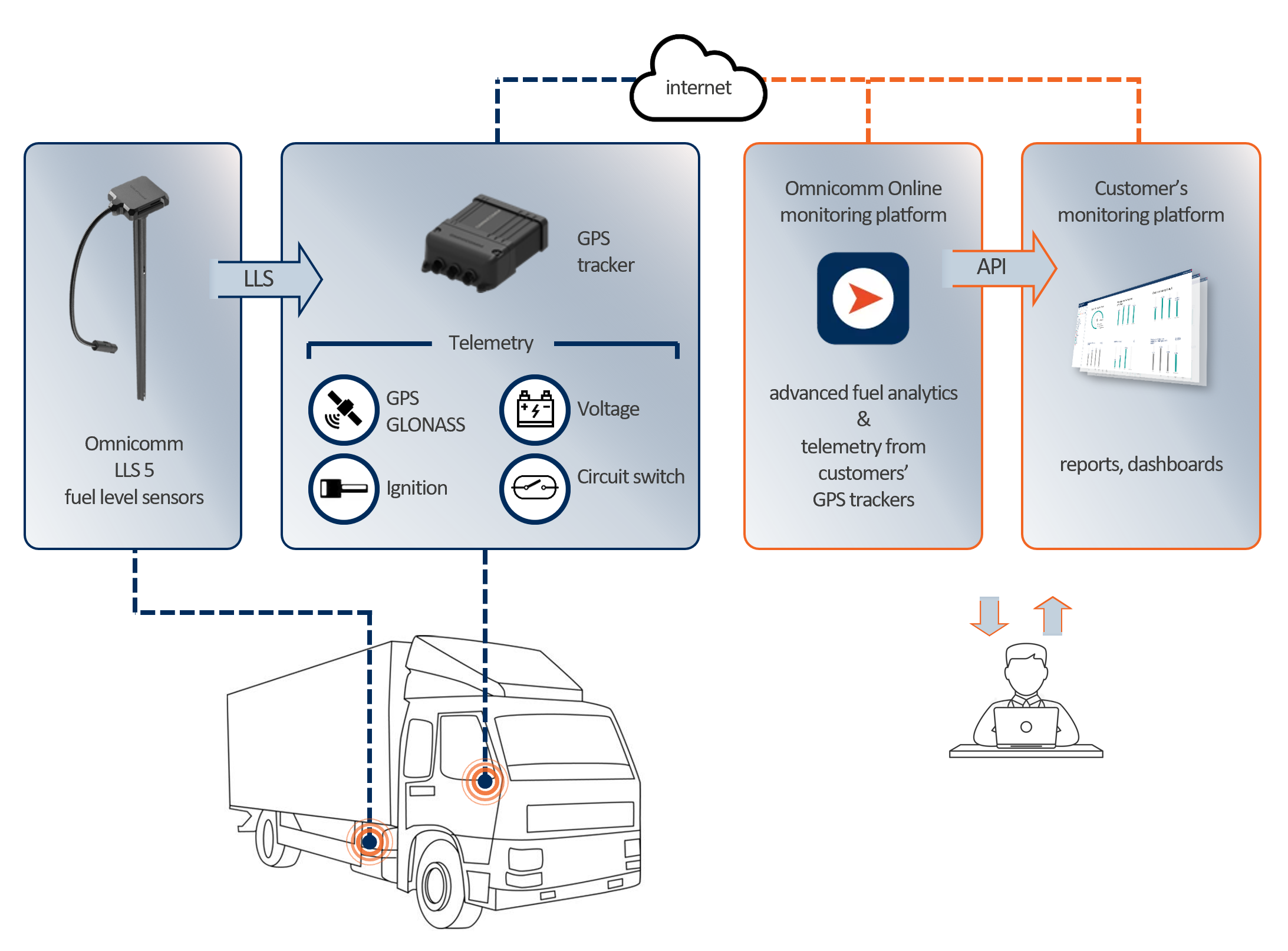

Single Tank Truck

This configuration describes a single-tank fuel delivery vehicle equipped with an Omnicomm fuel‑level sensor and GPS tracker.

It is an optimal solution for fleet operators that transport fuel in a standard (non-compartmentalized) tank, and need to monitor fuel level, vehicle location, operating parameters, and fuel consumption in real time.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 - 700mm | 1 |

| GPS-tracker Profi 3.0 / Optim 3.0 / Teltonika FMC125 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) [3PP] | 1 |

* [3PP] – 3rd party product

This minimal configuration already enables robust fuel and fleet monitoring; optional components (display, CAN reader) improve usability and data richness — useful for large-scale fleets, safety-critical operations, or environments requiring enhanced driver feedback.

Why These Components Are Recommended

Key advantages and strengths:

- The Omnicomm LLS 5 sensor provides up to 99.5% measurement accuracy, even under harsh conditions.

- It supports a broad measurement range (various probe lengths depending on the tank height) — making it suitable for standard tank‐trucks and also for different tank sizes if needed.

- With the proprietary fuel-analysis technology “FUELSCAN®”, the system compares physical characteristics of the loaded fuel with calibration fuel, computes a correction coefficient and automatically adjusts readings. This minimizes the need for manual recalibration or frequent maintenance.

This ensures that fuel level data remains reliable over time, even when fuel properties vary (e.g. different diesel batches), or during long-term operation of the tanker.

Recommended Reports in Omnicomm Online

To extract the most value from a single‑tank truck setup, these reports are especially useful:

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Engine Load, TPMS, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

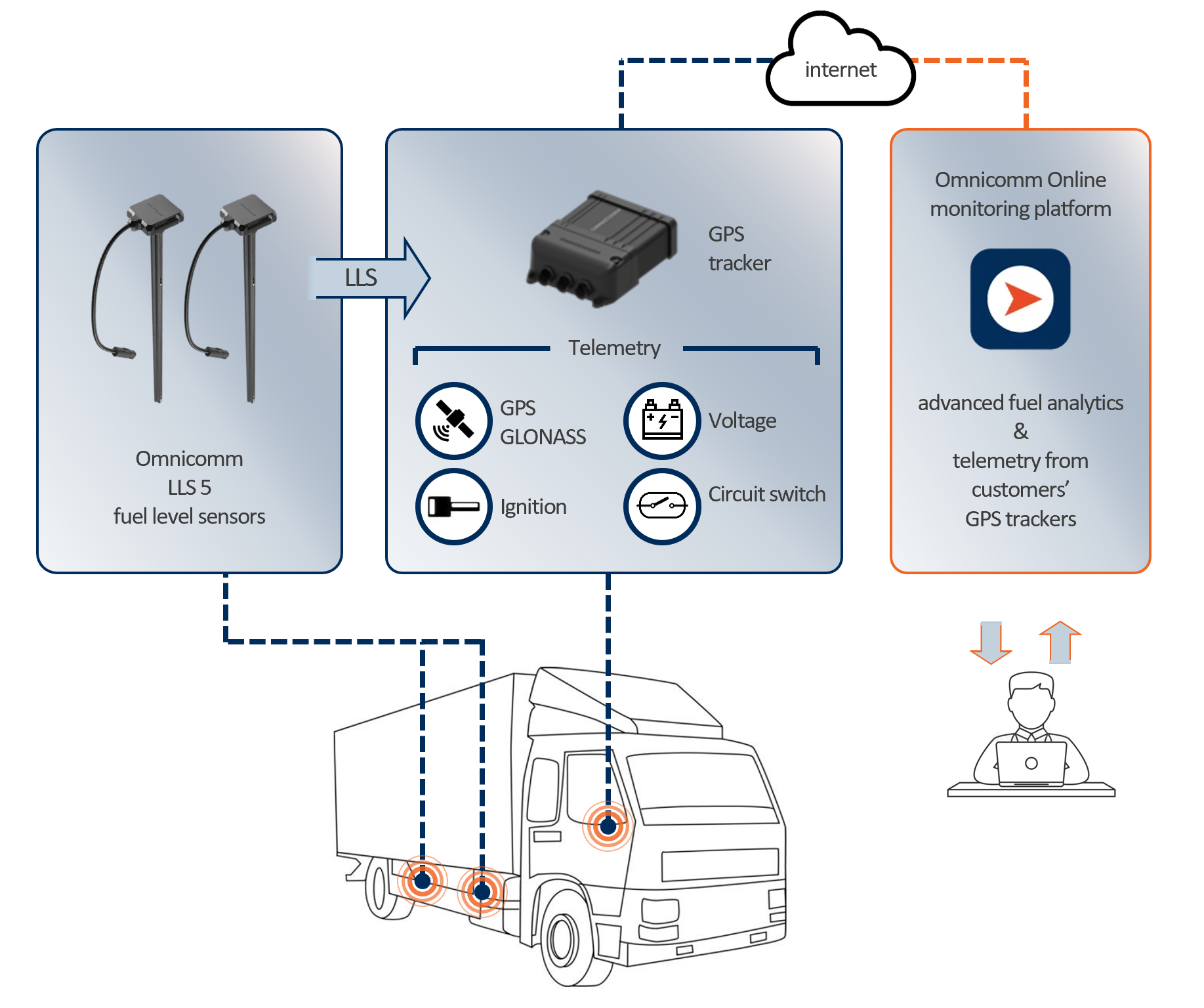

Double Tank Truck

This scenario describes a fuel delivery truck equipped with two separate fuel tanks (compartments) monitored independently using Omnicomm sensors. This setup is common in refuelers, tanker trucks, and service vehicles where managing multiple fuel compartments is critical for accurate inventory control, safety, and operational efficiency.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 - 700mm | 2 |

| GPS-tracker Profi 3.0 / Optim 3.0 / Teltonika FMC125 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) [3PP] | 1 |

* [3PP] – 3rd party product

Why These Components Are Recommended

Key Advantages and Strengths:

- By having separate fuel-level sensors for each tank, you get independent measurement of fuel in each compartment — enabling accurate tracking of fuel volume per tank, per delivery batch, or per compartment usage. This is especially important if the two tanks carry fuel for different purposes (e.g. distribution vs onboard reserve, or different fuel types) or serve different clients/sites.

- The level sensors (e.g. LLS 5) maintain high measurement accuracy and reliability under demanding conditions (fuel sloshing, vehicle tilts, temperature changes, vibrations).

- This eliminates ambiguity that arises if a single sensor were to monitor a combined (or unknown) fuel mixture across compartments, and helps avoid miscounts, losses, or misallocation — which is critical for accounting, billing, auditing, or safety compliance.

Recommended Reports in Omnicomm Online

For this double‑tank configuration, the following reports are particularly valuable:

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Engine Load, TPMS, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

* [3PP] – 3rd party product

Why Omnicomm

Omnicomm’s dual-tank solution delivers a proven, rugged, scalable, and integrated monitoring system — not just sensors. It combines sensor accuracy, robust hardware, flexible telemetry, and cloud analytics — ensuring that fleet operators get end-to-end control over fuel delivery, storage, usage, and fleet operation.

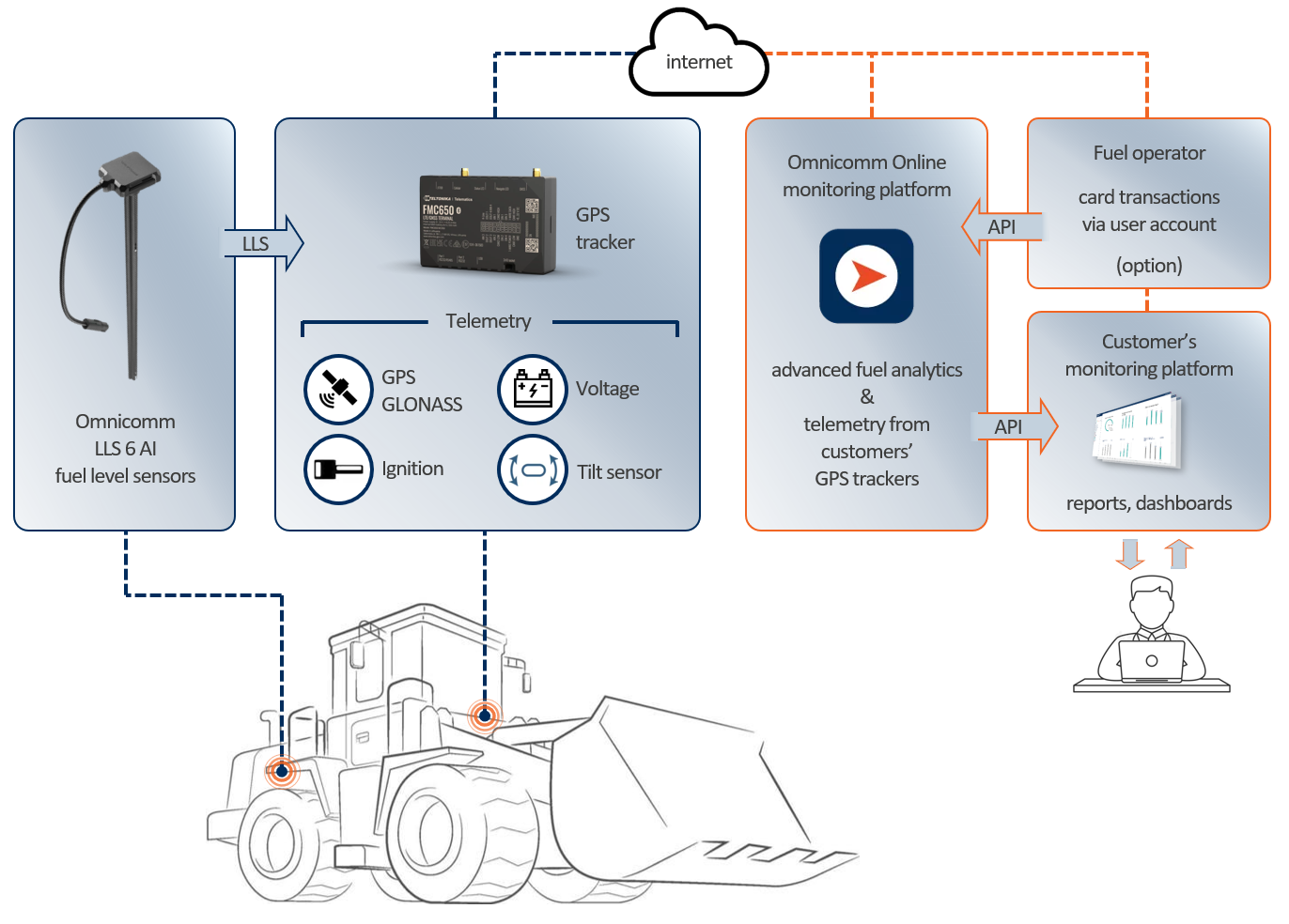

Mining & Construction

This configuration covers heavy‑duty equipment commonly used in mining, construction, road works, earth‑moving, or quarries: excavators, bulldozers, dump trucks, loaders, cranes, generators, stationary equipment, etc. The goal is to monitor fuel consumption, equipment operation (hours, load, idle time), location / geofencing, and fuel supply/dispensing for improved efficiency, safety and cost control.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 6 AI - 700mm | 1 |

| GPS-tracker Profi 3.0 / Teltonika FMC650 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) | 1 |

| Axle weight sensor | 1 |

| Manipulator tilt sensor | 1 |

Key Advantages and Strengths:

- The LLS sensors (LLS 4 or LLS 5) are purpose-built for heavy machinery, with high environmental resistance: robust casing, sealed connections, dust/water resistance, and ability to operate under heavy vibrations, jolts, dirt — common in mining/construction sites.

- High measurement accuracy ensures real fuel level readings even when fuel sloshing or varying fuel densities, which helps avoid under- or overestimation due to harsh operating conditions or terrain changes.

- Continuous, real‑time monitoring of fuel level enables immediate detection of refuels, draining, leaks, or unauthorized fuel removal — crucial in remote job‑site operations where manual fuel checks are impractical.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Group Work, Group Ratings, Custom Events |

* [3PP] – 3rd party product

Why Omnicomm

Omnicomm’s solutions are tailored for heavy‑duty, harsh‑environment industries: sensors with high accuracy and durability, trackers rated for vibration/dust/weather, flexible integration, and a unified cloud platform enabling fleet‑wide control. This translates into fuel cost savings, improved equipment efficiency, reduced losses, and reliable data for management and audits.

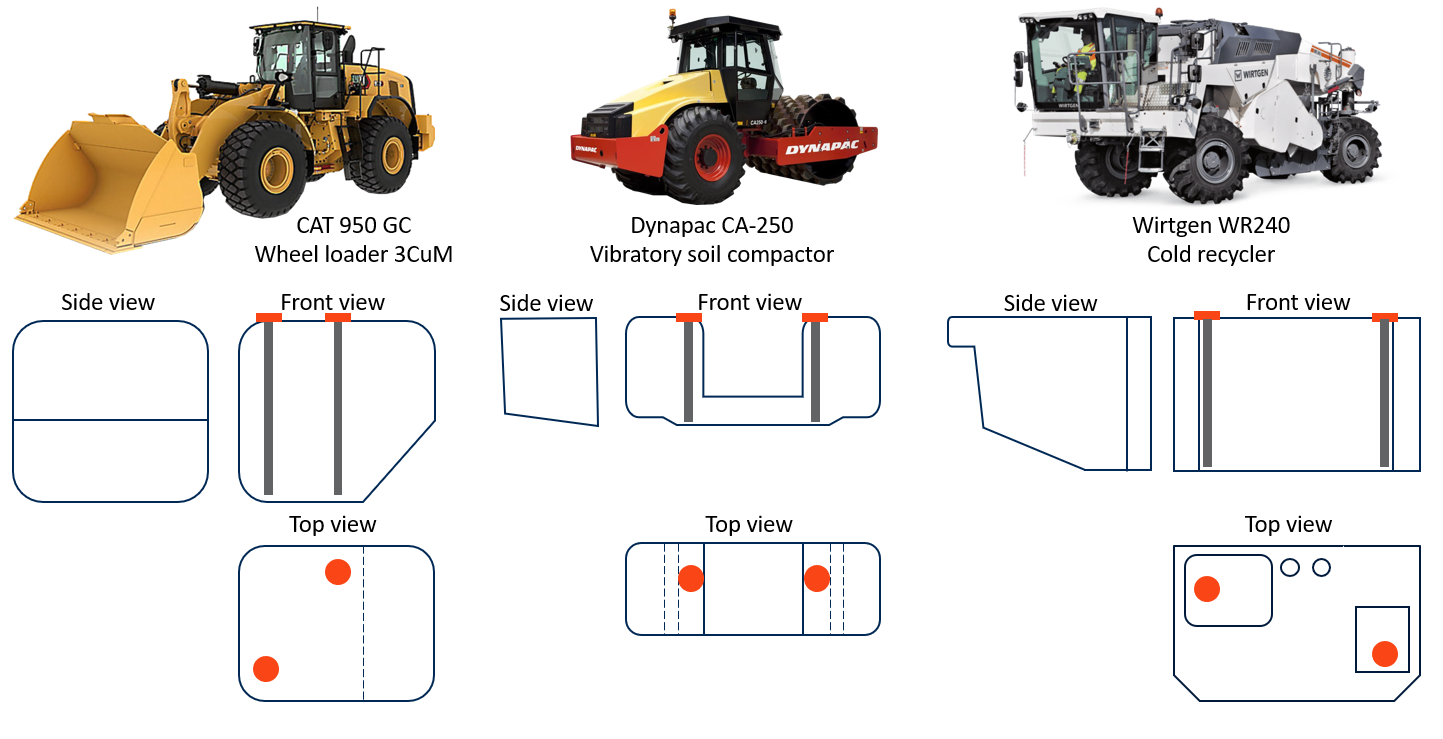

Various Shapes Of Fuel Tanks

In mining and construction equipment, fuel tanks often have complex and varied shapes — cylindrical drums, rectangular modules, baffle‑reinforced compartments, and other irregular designs. These shapes critically affect how well a fuel‑level sensor can measure volume. Proper placement, calibration, and installation are essential to ensure reliable, accurate readings.

Why Tank Shape Matters

- Heavy-duty machinery and construction/mining equipment often have non-standard or irregular-shaped fuel tanks (cylindrical, curved, non-rectangular, with internal reinforcements, baffles, ribs, sloped bottoms, etc.). The shape affects how accurately a fuel-level sensor measures fuel volume when the tank is partly filled, tilted, or under load.

- Irregular geometry, internal obstacles (ribs, stiffeners, internal structures), sloping bottoms, or non-uniform cross-sections may cause inaccurate readings, especially if a sensor is placed suboptimally — e.g. off-center, near a wall or rib, or where dead zones/residual pockets exist.

- For mobile heavy equipment, tilt, slope, or movement (uneven terrain) aggravate the problem: if sensor installation doesn’t compensate for such geometry/tilt, readings may fluctuate significantly, reducing reliability of fuel data — critical for monitoring in mining/construction contexts.

Therefore, correct selection and installation of fuel-level sensors must take tank shape fully into account.

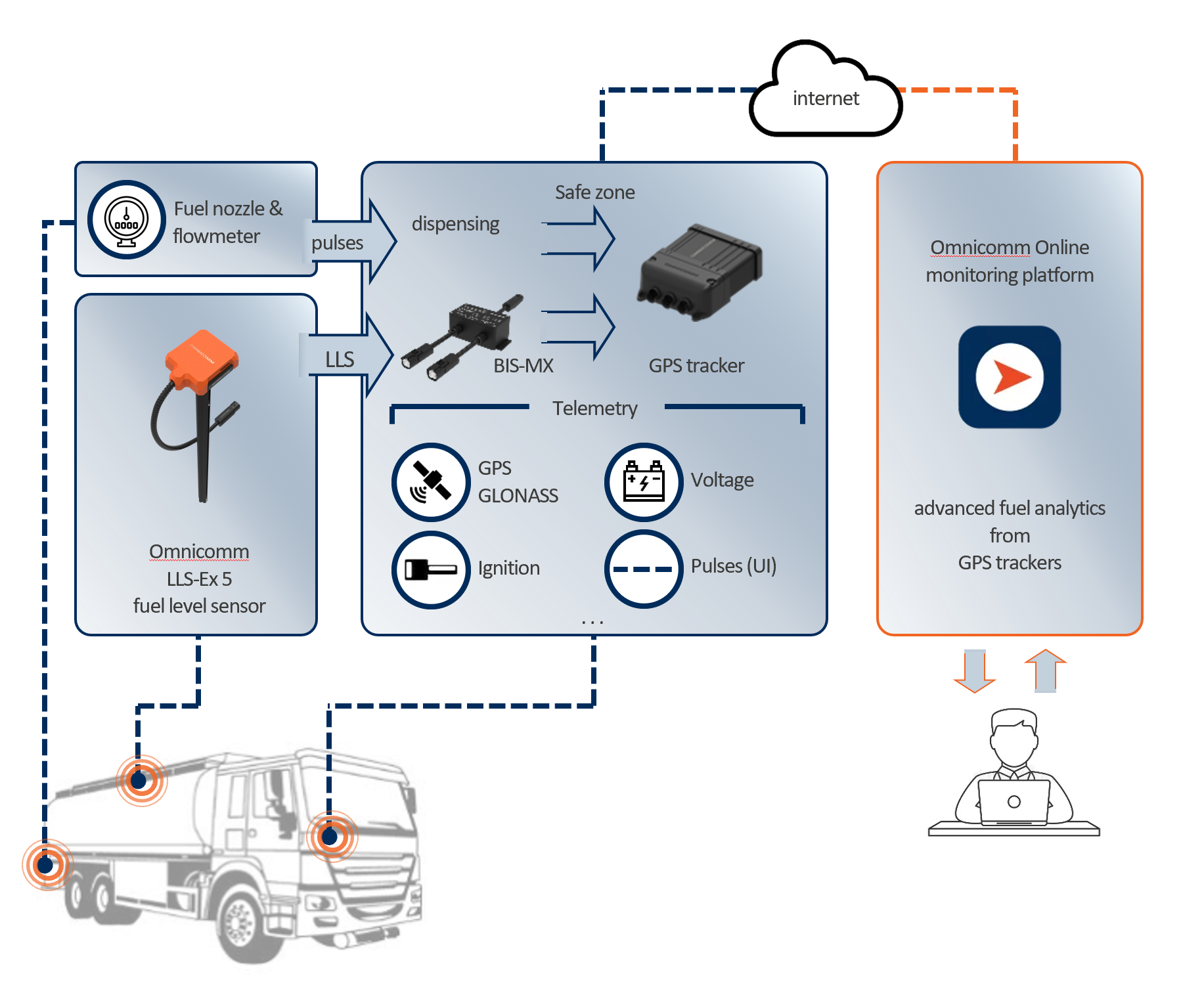

Fuel Bowser (With Dispensing)

A fuel bowser (also called a refueler) is a mobile or fixed vehicle / tank used to dispense fuel to other vehicles or equipment. In an Omnicomm monitoring setup, a bowser is equipped with fuel-level sensors, telemetry, and possibly flow meters to provide accurate data on fuel dispensing, fuel remaining, and fuel losses. This helps fleet operators maintain tight control of fuel operations and reduce losses.

This configuration covers mobile fuel-delivery units (fuel bowsers / tankers) that transport and dispense fuel to vehicles and equipment, with integrated fuel-level sensing, dispensing control, and full telemetry — enabling accurate tracking of fuel issuance, delivery volumes, equipment location, and fuel balance across fleet and stationary storage. It’s suitable for industrial fleets, construction/mining sites, remote operations, and any scenario where fuel is delivered from a tanker rather than a fixed station.

Typical Equipment Configuration:

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS-Ex 5 - 1500mm | 1 |

| Extension cable KTZ-MX 15 | 1 |

| GPS-tracker Profi 3.0 / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) [3PP] | 1 |

| Fuel flowmeter, pulse output, 60 l/min [3PP] | 1 |

* [3PP] – 3rd party product

This configuration provides a comprehensive toolkit for managing a mobile refueling operation, ensuring transparency from fuel intake to delivery and issuing, under telemetry control.

Key Advantages and Strengths:

- The system uses certified, high-precision digital sensors (LLS series) — not simple float-gauges — giving far better accuracy and reliability, reducing errors even under motion, sloshing, or varying fuel types.

- Full integration of fuel-level sensing + dispensing metering + telematics + cloud-based logging — offers end-to-end visibility, from fuel storage → tanker → customer vehicle — with minimal manual intervention.

- Safety components (spark-protection units, explosion-protected sensors) make it suitable even when handling flammable fuels, enabling compliance with safety regulations.

- Flexibility and scalability — works for small single-tanker bowsers or large multi-compartment tankers; allows addition of more sensors, flow meters, driver-authentication, telemetry — adapting to business growth or changing operational needs.

- Automated reporting — fuel dispensing logs, fuel balance, deviations, fueling history — reduce administrative overhead, support audit/fuel card reconciliation, help detect theft or inefficiencies.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Dispensing, Refueler Statement, Fuel Balance, MultiTank | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips |

Why Omnicomm

Omnicomm’s solution combines precision sensors, robust industrial-grade components, telemetry, and cloud analytics — delivering a reliable, scalable, safe, and efficient fuel-bowser monitoring and control system. This ensures cost savings, reduces fuel losses or theft, automates logs, and streamlines operations for businesses with fuel distribution needs.

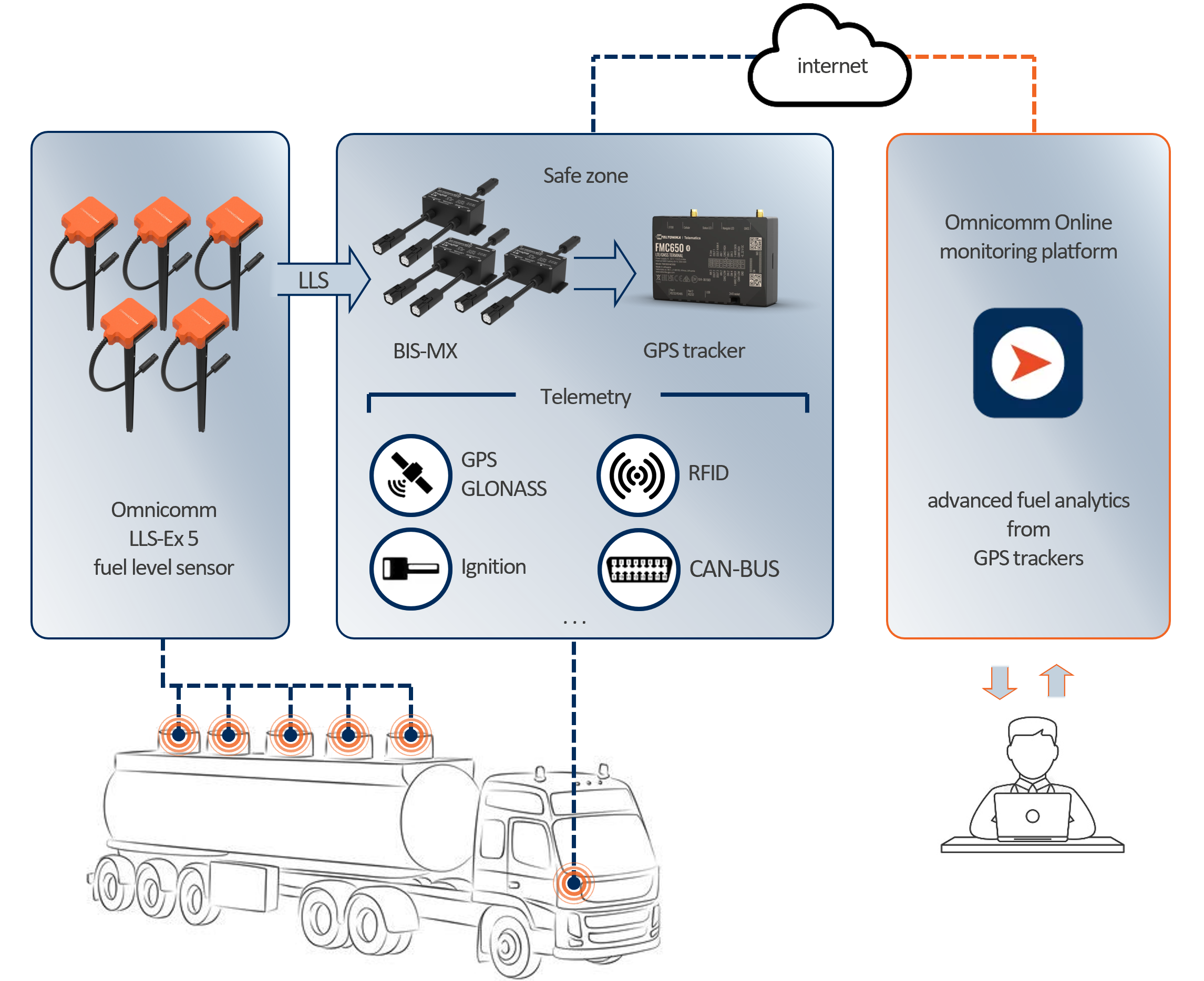

Fuel Delivery Truck (5 compartments)

A “Fuel Delivery Truck” is a tanker or refueler vehicle used to deliver and issue fuel (diesel, gasoline, etc.) to other vehicles, machines, or storage facilities. When equipped with Omnicomm’s fuel-level sensors, flow meters, telematics, and cloud services, it enables precise control and logging of fuel delivery, tanker balance, dispensing events, and fleet-wide fuel flows.

Fuel delivery trucks usually have from one to six fuel compartments in the tank, each equipped with a separate LLS-Ex 5 sensor. The spark protection unit and the tracker are located in the explosion-proof area, usually in the driver's cab.

Typical Equipment Configuration:

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS-Ex 5 - 2000mm | 5 |

| BIS-MX spark protection unit | 3 |

| Extension cable KTZ-MX 15 | 3 |

| Extension cable KTZ-MX 20 | 2 |

| GPS-tracker Profi 3.0 / Teltonika FMC650 / … | 1 |

| KTZ-MX splitter | 2 |

| Omnicomm Online service license | 1 |

| Options | |

| RFID reader (MIFARE or EM-Marin, DS1990A emul.) [3PP] | 1 |

| Wireless CAN-bus reader(s) | 1 |

Key advantages and strengths:

- LLS sensors deliver high-accuracy fuel measurement (error within about 0.5 %) even under motion, vibrations, temperature changes, and varying fuel properties — ensuring reliable tanker-tank level readings.

- When paired with a flow meter and signal reader, the system logs exact dispensed volumes during each refueling operation, allowing reconciliation between tanker inventory and issued fuel, reducing unaccounted losses.

- Explosion-proof sensor variants + protective units enable safe operation with flammable fuels, meeting safety requirements in fuel-handling contexts.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance, MultiTank | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, TPMS, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

Why Omnicomm

Omnicomm’s solution combines industry-leading fuel-level sensor accuracy and robustness, modular and scalable hardware (sensors, flow meters, terminals, displays), and a powerful cloud-based management system. This combination ensures that fuel delivery operations are efficient, transparent, safe, and scalable.

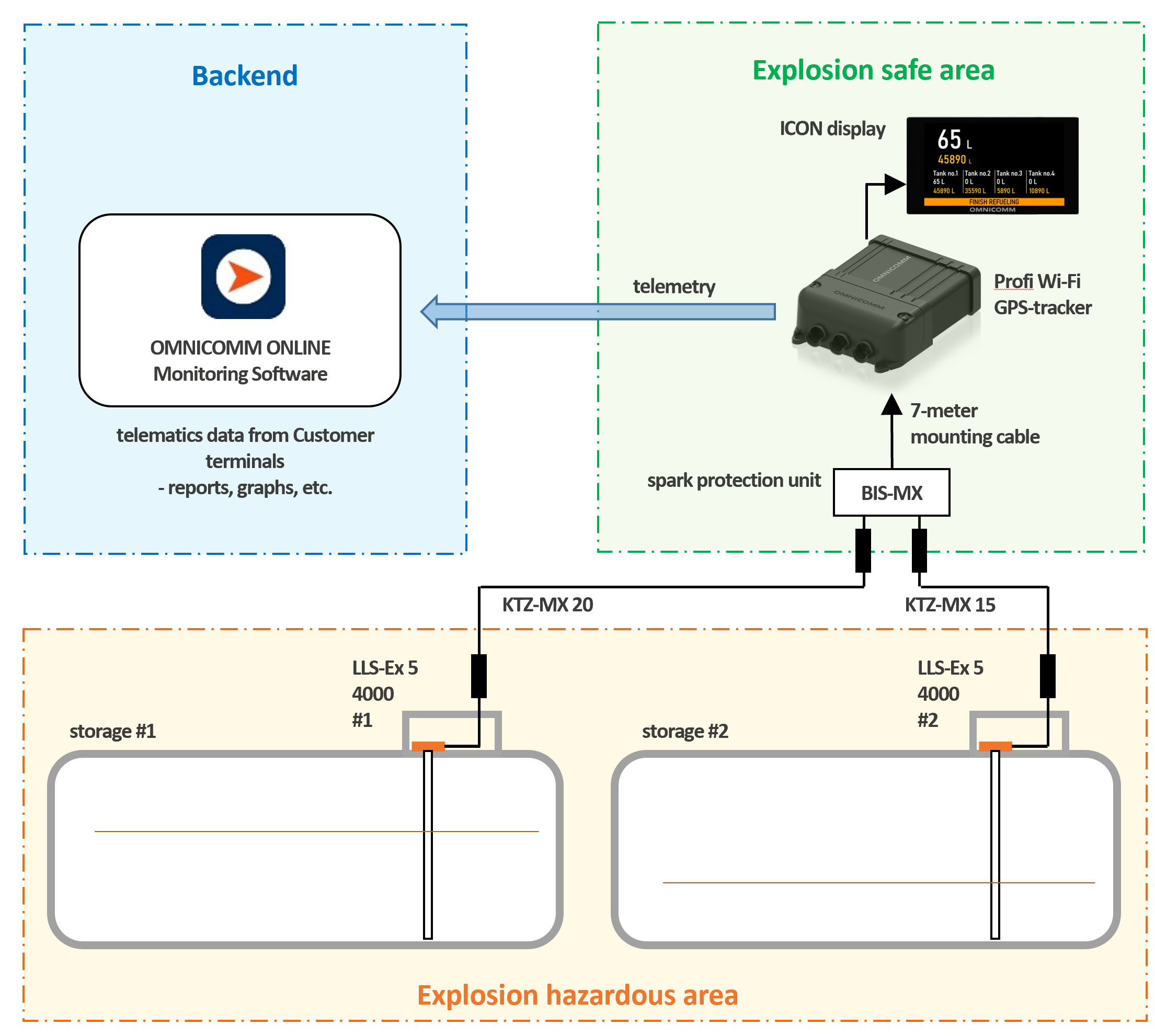

Gas Station Monitoring

This configuration describes a system for monitoring fuel storage and dispensing at petrol/diesel filling stations (stationary fuel storage tanks + dispensers), using Omnicomm-compatible sensors, telemetry, and cloud-based monitoring. It enables accurate fuel-stock accounting, real-time tracking of dispensing events, leak/drain detection, automatic alerts, and historical reporting — making it useful for fuel retailers, fleet depots, corporate garages, or fuel storage depots.

A solution for petrol stations can include at least explosion-protected LLS-Ex 5 sensors installed in the tanks, a GPS tracker and a monitoring platform. In addition, an ICON display, an end switches for access control, etc. can be optionally available.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS-Ex 5 - 2000mm | 2 |

| BIS-MX spark protection unit | 1 |

| Extension cable KTZ-MX 15 | 1 |

| Extension cable KTZ-MX 20 | 1 |

| GPS-tracker Profi 3.0 Wi-Fi / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| End-position sensors [3PP] | 2 |

* [3PP] – 3rd party product

Why These Components Are Recommended

Key Advantages and Strengths:

- Fuel-level sensors provide precise measurement of volume in storage tanks, reducing reliance on manual dip-sticks or periodic manual measurements — improving accuracy and consistency over time.

- Automated logging of fuel dispensing (via flow meters on dispensers) ensures that each liter dispensed is counted, correlated with fuel-stock decrease, enabling transparent reconciliation between stock and issued fuel — reducing losses from theft, leaks, or mis-dispensing.

- Real-time monitoring and alerts: threshold notifications (low-stock, high-dispense volume, sudden volume drop — potential leak or unauthorized draining) help maintain safety, compliance and operational continuity.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance, MultiTank | - | - | Statistics, Summary Report | Voltage, Auxiliary Equipment Operation, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Log |

Omnicomm’s solution combines industrial-grade sensors, robust telemetry, secure data logging, and scalable cloud-based management — providing a reliable, transparent, safe, and efficient fuel-station monitoring system that outperforms manual or generic approaches.

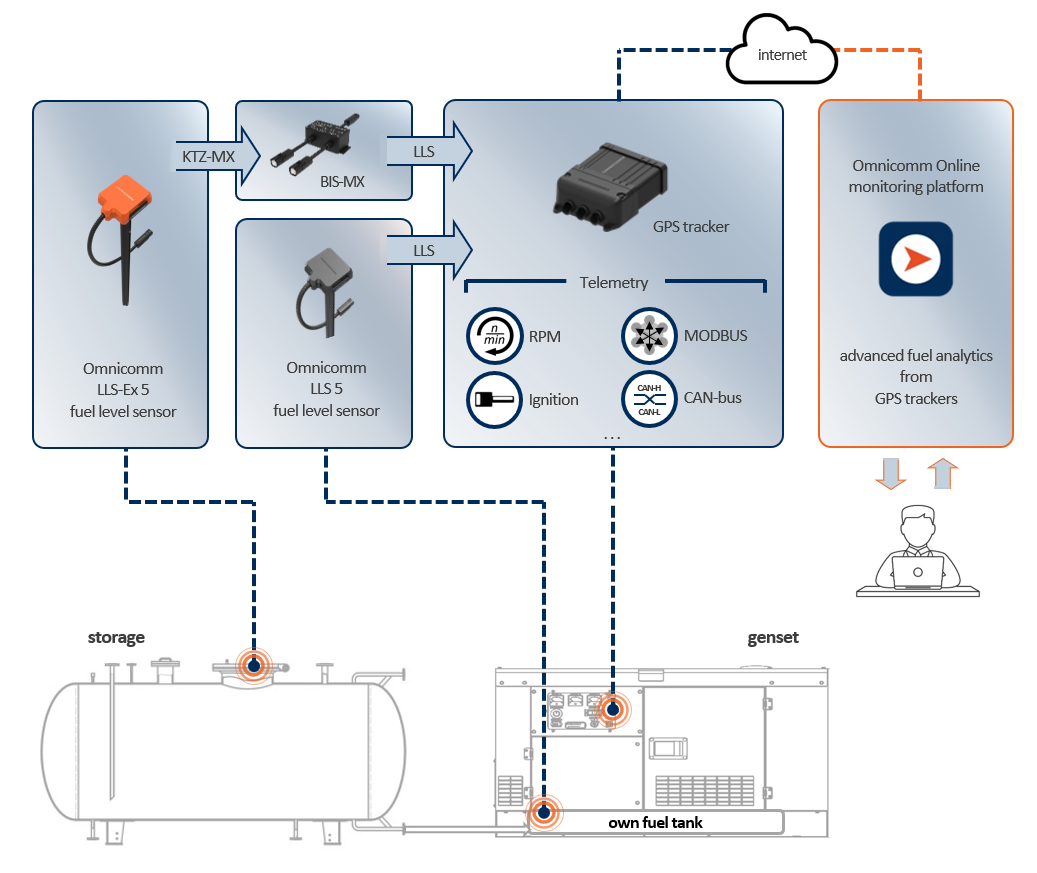

Genset Monitoring

Generator sets (gensets) are widely used as primary or backup power sources in industrial facilities, construction sites, remote operations, telecom towers, mining camps, and critical infrastructure. Continuous monitoring of fuel levels, engine runtime, load patterns, and consumption is essential for preventing downtime, ensuring reliable operation, optimizing fuel use, and detecting theft or abnormal behavior.

Omnicomm fuel-level sensors and telematics solutions enable accurate, real-time monitoring of genset fuel tanks and operating parameters. This helps operators maintain fuel autonomy, plan timely refueling, reduce fuel losses, and improve overall equipment efficiency.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 | 1 |

| BIS-MX spark protection unit | 1 |

| Extension cable KTZ-MX 20 | 1 |

| GPS-tracker Profi Wi-Fi 3.0 / Optim 3.0 / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) | 1 |

Why These Components Are Recommended

Key Advantages and Strengths:

- Reduced fuel losses through theft detection and clear accountability.

- Zero unplanned outages thanks to fuel autonomy monitoring and timely refueling planning.

- Improved operational efficiency based on accurate consumption and runtime analytics.

- Lower maintenance costs due to early detection of abnormal behavior and automatic runtime tracking.

- Enhanced transparency for contractors, remote workers, and fuel suppliers.

- List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance, MultiTank | Location | - | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, TPMS, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Visiting the Geofences, Log, Custom Events |

A sample set of reports and options specific to monitoring in various industries. This set may vary from case to case

| Fuel monitoring | Movement & GPS monitoring | Genset utilization & overloads | CAN Bus readings | Auxiliary equipment | Geofences & routes | CO2 emissions (standstills) | Remote disabling | RFID/iButton (authorization) | |

|---|---|---|---|---|---|---|---|---|---|

| Data centers | + | + | + | + | |||||

| Telecom | + | + | + | + | |||||

| Fuel stations | + | + | + | ||||||

| Banks | + | + | + | + | |||||

| Hospitals | + | + | + | + | + | ||||

| Construction | + | + | + | + | + | + | |||

| Leasing | + | + | + | + | + | + | + | ||

| Where does the data come from | LLS sensors, CAN-bus, VH dashboard, aux-equipment | Terminal | Terminal (RPM, temperature sensors, aux-equipment), CAN-bus, MODBUS | CAN-bus | Terminal, aux-equipment | Terminal | Terminal, CAN-bus | Terminal & 3rd-party equipment (relays) | Terminal & 3rd-pary equipment, ICON |

Why Omnicomm

High-precision fuel-level sensors ensure reliable monitoring even in harsh conditions.

Industrial-grade telematics designed for vibration, dust, heat, and high-load environments.

Flexible integration via analog, RS-485, CANBus, Modbus, and digital I/O.

Real-time cloud monitoring with detailed anomaly detection and event history.

Scalable architecture – suitable for single gensets or large distributed fleets.

Proven reliability in telecom, mining, and energy operations globally.

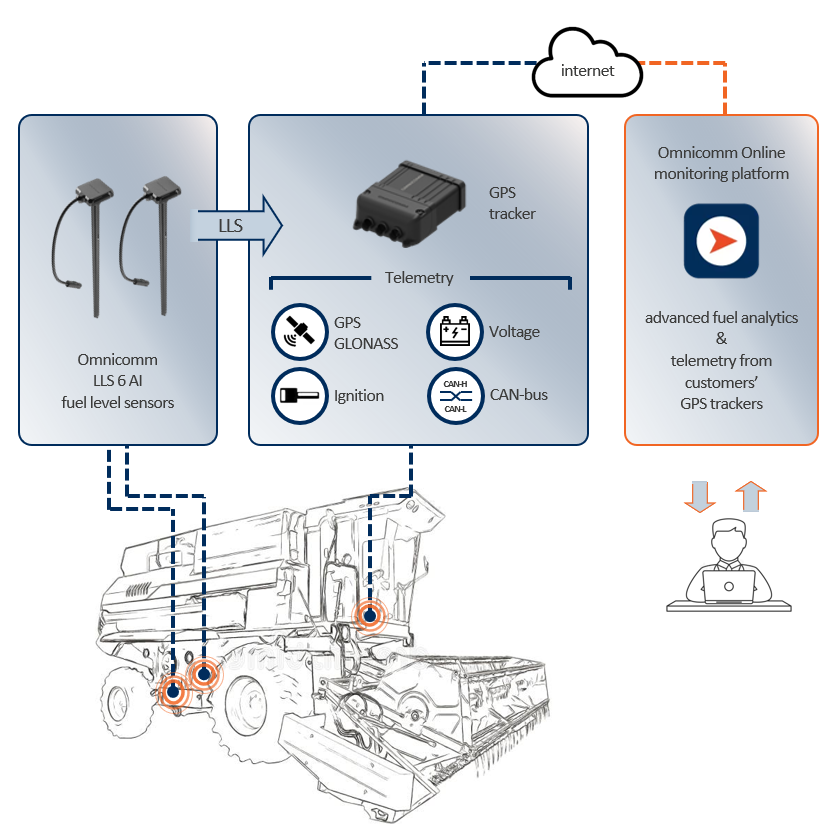

Agriculture

In agricultural settings (farms, plantations, seasonal work, remote fields), reliable monitoring of fuel, machinery usage, and resource consumption is critical. Fuel-powered equipment — tractors, combine harvesters, irrigation pumps, fuel bowsers, sprayers, generators — often work in remote, distributed locations. Monitoring fuel levels, consumption, dispensing, and machine operation helps optimize efficiency, reduce fuel losses and theft, schedule maintenance, and manage resources transparently.

Omnicomm offers tailored monitoring solutions for agricultural machinery, utilizing LLS sensors to accurately measure fuel levels alongside comprehensive monitoring of basic telemetry and various auxiliary equipment. Our system integrates data from CAN bus interfaces, providing real-time insights that enhance operational efficiency, optimize fuel consumption, and support effective management of agricultural equipment in diverse field conditions.

Using Omnicomm sensors and telemetry combined with remote monitoring, farms and agri-enterprises can maintain control over fuel supply, equipment use, and operational costs even in distributed or remote conditions.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 6 AI | 2 |

| GPS-tracker Profi 3.0 / Optim 3.0 / Teltonika FMC125 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| CAN-bus reader(s) | 1 |

Key Advantages and Strengths:

- Accurate Fuel Inventory & Issuance Control

- Machine Utilization, Logistics and Operational Transparency

- Cost Savings, Loss Prevention & Efficiency

- Flexibility and Scalability

Recommended Reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, TPMS, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

Why Omnicomm

Reliable fuel-level sensors (LLS series) designed to handle motion, vibrations, tilting — suitable for off-road, rough-terrain agricultural machinery.

Modular telemetry and monitoring system — works across different equipment types (vehicles, stationary units, bowsers), allowing flexible deployment.

Transparent fuel accounting and dispensing logging — ensures accountability for all fuel issued or consumed, reducing possibility of unaccounted losses, theft, or misuse.

Scalable architecture — from a single tractor to a large fleet across multiple farms or fields. Data aggregation and reporting make management and decision-making easier.

Operational insights and efficiency improvements — by combining fuel consumption, location, runtime and usage data, managers can derive metrics (fuel per hectare, fuel per hour, idle vs work time), identify inefficiencies, and optimize workflows.

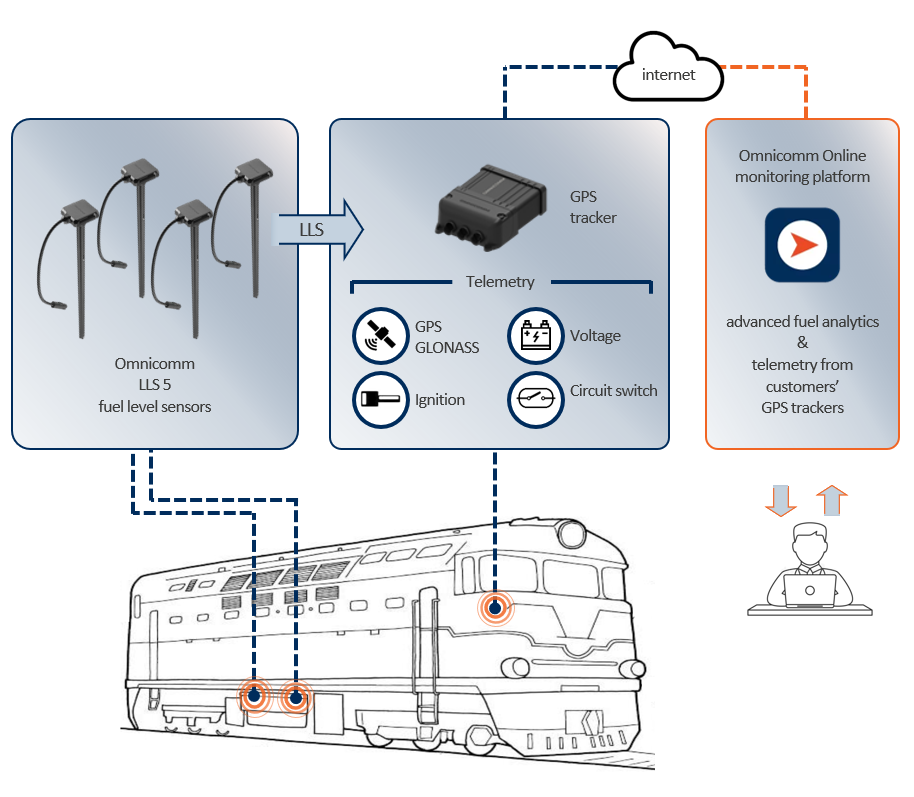

Diesel Locomotives

Diesel-powered locomotives — used in freight transport, shunting yards, industrial rail, mines, and long-haul railways — often consume significant amounts of fuel. Accurately monitoring fuel levels, consumption, refuels and drains, engine operating hours, and runtime behavior is essential for cost control, theft prevention, maintenance planning, and operational transparency.

A monitoring system based on fuel-level sensors, telemetry, and onboard data logging can transform a standard locomotive into a “smart” asset: enabling remote control, fuel accountability, usage analytics — which is particularly important in rail fleets, industrial complexes, mining operations, or enterprises managing multiple locomotives across sites.

Omnicomm provides advanced monitoring solutions for diesel locomotives, recommending the use of 2 to 4 LLS sensors to minimize measurement errors and ensure accurate fuel level readings. Our system offers comprehensive monitoring of essential telemetry data, enabling precise tracking of fuel consumption and operational parameters to optimize locomotive performance and maintenance.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 - 700mm | 4 |

| GPS-tracker Profi 3.0 / Optim 3.0 / Teltonika FMC125 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| End-position (сircuit switch) sensors [3PP] | 2 |

Key Advantages and Strengths:

- Real-time tracking of fuel level in large diesel tanks prevents surprises and enables proactive refueling — minimizing downtime.

- Logs refuel and drain events, making fuel supply transparent and enabling reconciliation between consumed and recorded fuel.

- Helps detect fuel theft or unauthorized draining, especially important for remote rail yards or unattended locomotives.

Recommended Reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, MultiTank | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

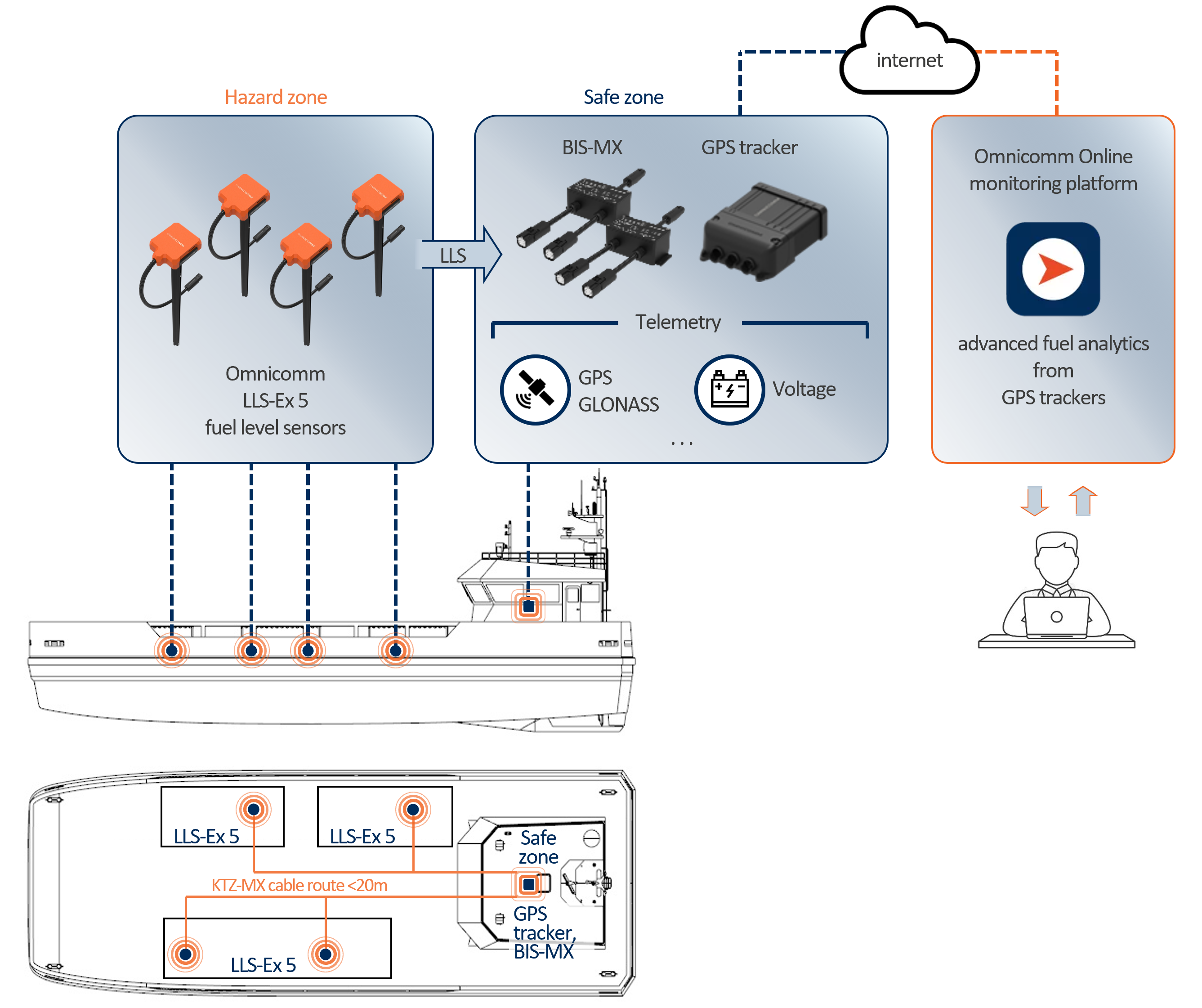

Maritime

Marine vessels — whether cargo ships, tankers, supply barges, workboats, service vessels, or small/medium craft — operate in challenging conditions: fuel consumption is high, tanks may have non‑standard shapes, refueling may occur at ports or remote moorings, and fuel losses or theft are possible. Monitoring fuel levels, consumption, fuel transfers, engine runtime, and vessel location is critical for cost control, safety, compliance, and operational transparency.

With Omnicomm fuel‑level sensors, telemetry, and remote monitoring, shipowners and operators can equip vessels with a “smart monitoring” system — tracking fuel stock, usage, refueling events, vessel position, and generating reports for audits, fuel management, and operational planning.

Omnicomm offers specialized maritime monitoring solutions featuring LLS-Ex 5 sensors designed for large fuel tanks, ensuring precise fuel level measurements in demanding marine environments. Our system provides comprehensive monitoring of basic telemetry and additional onboard equipment, with the optional capability to transmit GPS tracker data via Wi-Fi, enabling enhanced vessel tracking and operational oversight.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS-Ex 5 - 2500mm | 4 |

| BIS-MX spark protection unit | 2 |

| Extension cable KTZ-MX 20 | 3 |

| Extension cable KTZ-MX 15 | 1 |

| GPS-tracker Profi 3.0 Wi-Fi / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| End-position (сircuit switch) sensors [3PP] | 2 |

Key Advantages and Strengths:

- Continuous real‑time monitoring of fuel volume in vessel tanks, regardless of pitch/roll or sea state, gives accurate inventory data.

- Automatic detection and logging of refueling or fuel transfers (bunkering), fuel dispensing to auxiliary engines or generators, and consumption over voyages.

- Enables detection of sudden fuel loss (possible theft, siphoning, leak) — critical for marine safety, loss prevention, and compliance.

Recommended Reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, MultiTank | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | Voltage, Auxiliary Equipment Operation, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Visiting the Geofences, Log, Trip Report, Active Trips, Custom Events |

Digital fuel‑level sensors and telemetry overcome limitations of manual gauges and float‑based instruments, which are affected by motion, sloshing, and irregular tank geometry — common in marine environments.

Combined fuel-volume tracking, GNSS tracking, and data logging provide full visibility not only of fuel, but of vessel position, usage, and operations — supporting efficient fleet management and logistics.

Modular architecture — supports simple single‑tank vessels or complex multi‑tank / multi‑vessel fleets, with optional add-ons (fuel transfer metering, bunkering logging, engine telemetry).

Supports remote monitoring and centralized management — ideal for shipping companies, marine service providers, offshore operations, and fleets spread across wide geographic regions.

Provides audit‑ready fuel and operation logs — useful for compliance, client billing, supplier accounting, or internal fuel/spending control.