Fuel Bowser (With Dispensing)

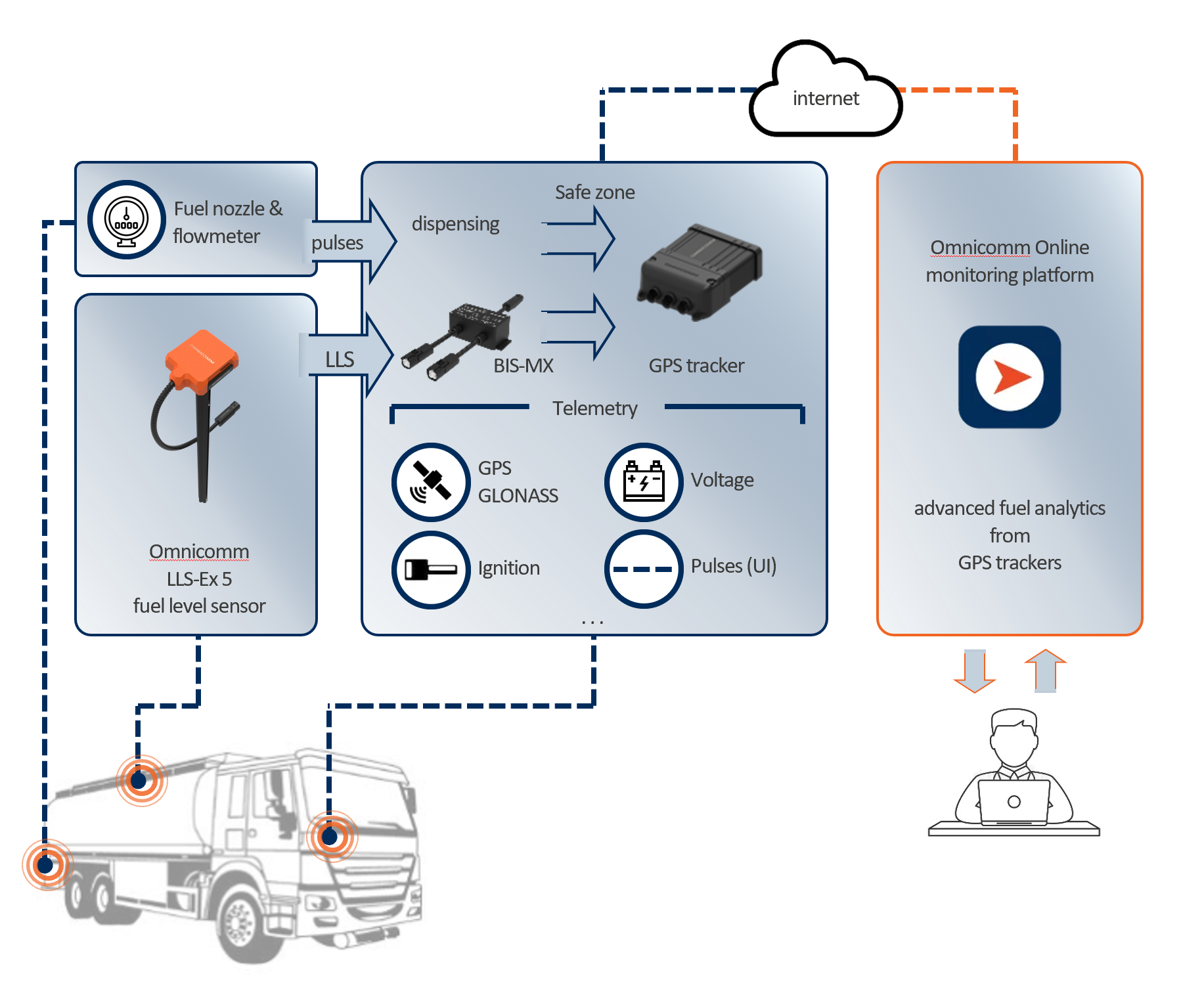

A fuel bowser (also called a refueler) is a mobile or fixed vehicle / tank used to dispense fuel to other vehicles or equipment. In an Omnicomm monitoring setup, a bowser is equipped with fuel-level sensors, telemetry, and possibly flow meters to provide accurate data on fuel dispensing, fuel remaining, and fuel losses. This helps fleet operators maintain tight control of fuel operations and reduce losses.

This configuration covers mobile fuel-delivery units (fuel bowsers / tankers) that transport and dispense fuel to vehicles and equipment, with integrated fuel-level sensing, dispensing control, and full telemetry — enabling accurate tracking of fuel issuance, delivery volumes, equipment location, and fuel balance across fleet and stationary storage. It’s suitable for industrial fleets, construction/mining sites, remote operations, and any scenario where fuel is delivered from a tanker rather than a fixed station.

Typical Equipment Configuration:

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS-Ex 5 - 1500mm | 1 |

| Extension cable KTZ-MX 15 | 1 |

| GPS-tracker Profi 3.0 / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) [3PP] | 1 |

| Fuel flowmeter, pulse output, 60 l/min [3PP] | 1 |

* [3PP] – 3rd party product

This configuration provides a comprehensive toolkit for managing a mobile refueling operation, ensuring transparency from fuel intake to delivery and issuing, under telemetry control.

Key Advantages and Strengths:

- The system uses certified, high-precision digital sensors (LLS series) — not simple float-gauges — giving far better accuracy and reliability, reducing errors even under motion, sloshing, or varying fuel types.

- Full integration of fuel-level sensing + dispensing metering + telematics + cloud-based logging — offers end-to-end visibility, from fuel storage → tanker → customer vehicle — with minimal manual intervention.

- Safety components (spark-protection units, explosion-protected sensors) make it suitable even when handling flammable fuels, enabling compliance with safety regulations.

- Flexibility and scalability — works for small single-tanker bowsers or large multi-compartment tankers; allows addition of more sensors, flow meters, driver-authentication, telemetry — adapting to business growth or changing operational needs.

- Automated reporting — fuel dispensing logs, fuel balance, deviations, fueling history — reduce administrative overhead, support audit/fuel card reconciliation, help detect theft or inefficiencies.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Dispensing, Refueler Statement, Fuel Balance, MultiTank | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips |

Why Omnicomm

Omnicomm’s solution combines precision sensors, robust industrial-grade components, telemetry, and cloud analytics — delivering a reliable, scalable, safe, and efficient fuel-bowser monitoring and control system. This ensures cost savings, reduces fuel losses or theft, automates logs, and streamlines operations for businesses with fuel distribution needs.