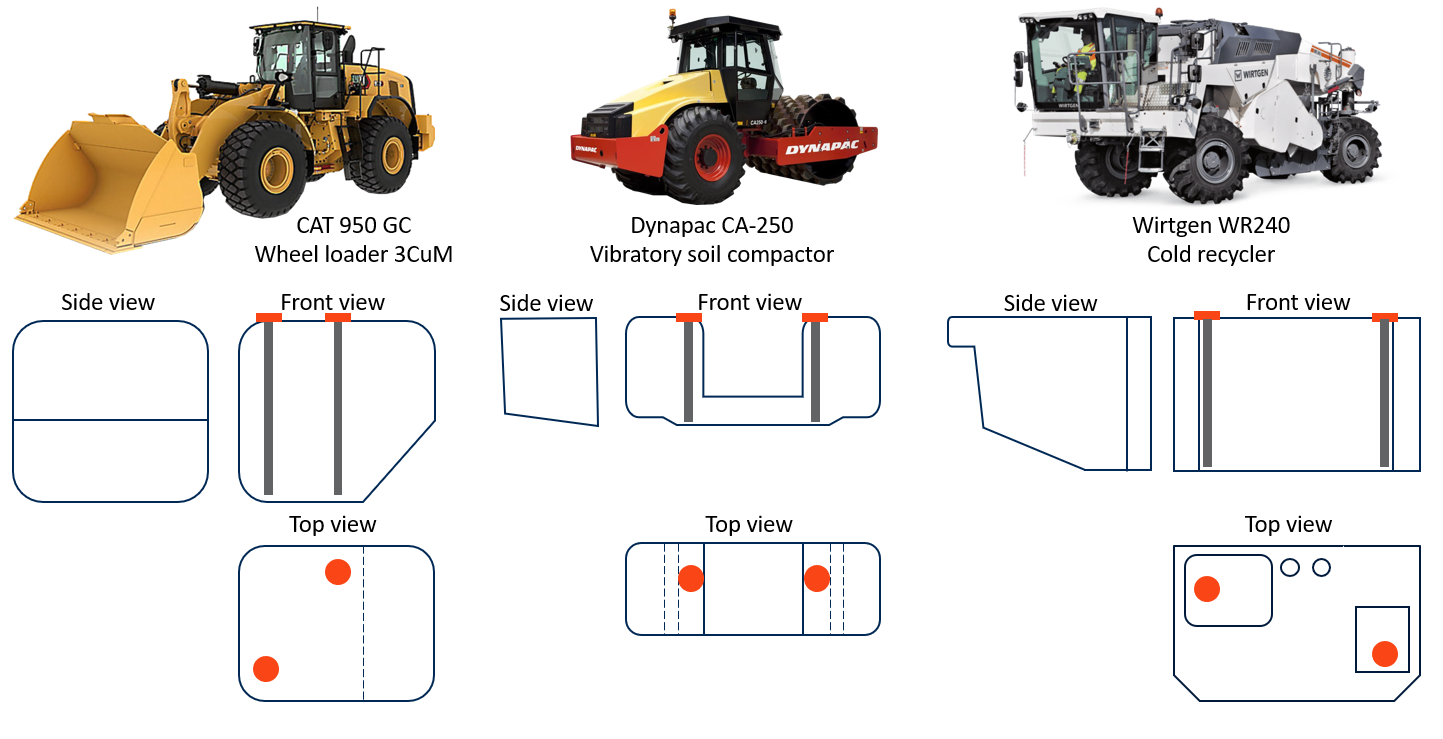

Various Shapes Of Fuel Tanks

In mining and construction equipment, fuel tanks often have complex and varied shapes — cylindrical drums, rectangular modules, baffle‑reinforced compartments, and other irregular designs. These shapes critically affect how well a fuel‑level sensor can measure volume. Proper placement, calibration, and installation are essential to ensure reliable, accurate readings.

Why Tank Shape Matters

- Heavy-duty machinery and construction/mining equipment often have non-standard or irregular-shaped fuel tanks (cylindrical, curved, non-rectangular, with internal reinforcements, baffles, ribs, sloped bottoms, etc.). The shape affects how accurately a fuel-level sensor measures fuel volume when the tank is partly filled, tilted, or under load.

- Irregular geometry, internal obstacles (ribs, stiffeners, internal structures), sloping bottoms, or non-uniform cross-sections may cause inaccurate readings, especially if a sensor is placed suboptimally — e.g. off-center, near a wall or rib, or where dead zones/residual pockets exist.

- For mobile heavy equipment, tilt, slope, or movement (uneven terrain) aggravate the problem: if sensor installation doesn’t compensate for such geometry/tilt, readings may fluctuate significantly, reducing reliability of fuel data — critical for monitoring in mining/construction contexts.

Therefore, correct selection and installation of fuel-level sensors must take tank shape fully into account.