Genset Monitoring

Generator sets (gensets) are widely used as primary or backup power sources in industrial facilities, construction sites, remote operations, telecom towers, mining camps, and critical infrastructure. Continuous monitoring of fuel levels, engine runtime, load patterns, and consumption is essential for preventing downtime, ensuring reliable operation, optimizing fuel use, and detecting theft or abnormal behavior.

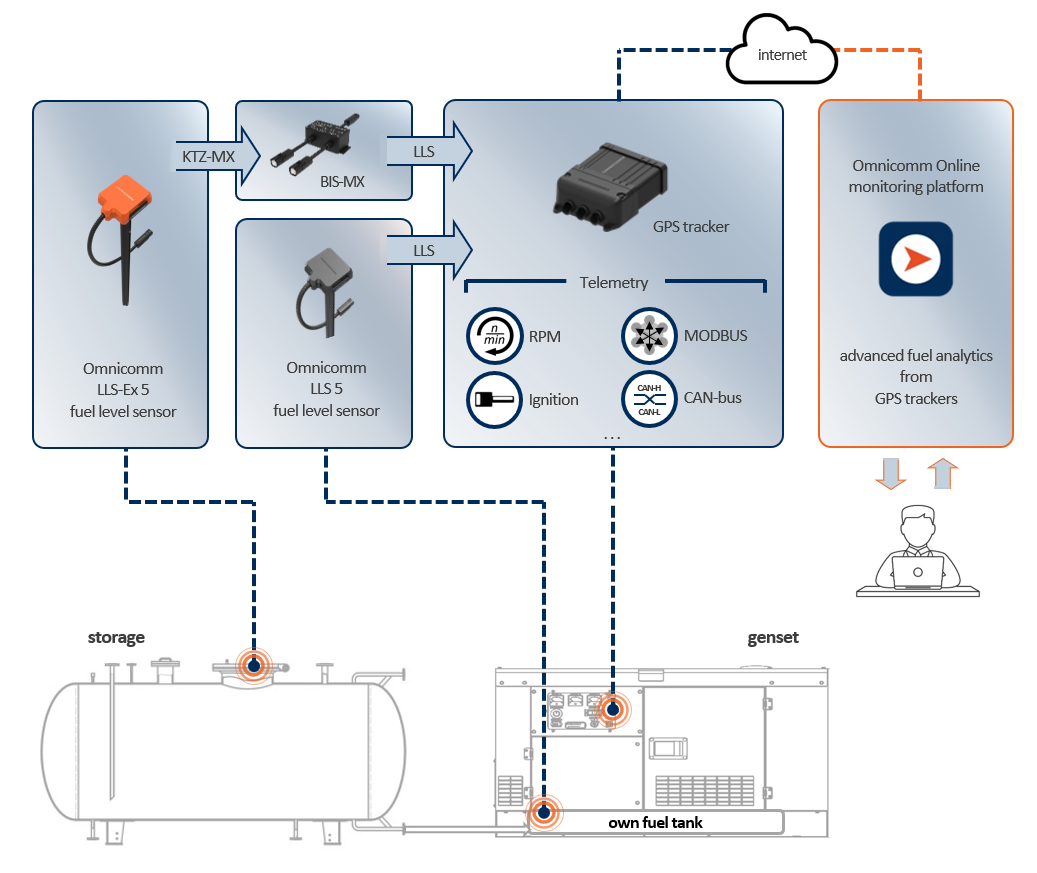

Omnicomm fuel-level sensors and telematics solutions enable accurate, real-time monitoring of genset fuel tanks and operating parameters. This helps operators maintain fuel autonomy, plan timely refueling, reduce fuel losses, and improve overall equipment efficiency.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 5 | 1 |

| BIS-MX spark protection unit | 1 |

| Extension cable KTZ-MX 20 | 1 |

| GPS-tracker Profi Wi-Fi 3.0 / Optim 3.0 / Teltonika FMC650 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) | 1 |

Why These Components Are Recommended

Key Advantages and Strengths:

- Reduced fuel losses through theft detection and clear accountability.

- Zero unplanned outages thanks to fuel autonomy monitoring and timely refueling planning.

- Improved operational efficiency based on accurate consumption and runtime analytics.

- Lower maintenance costs due to early detection of abnormal behavior and automatic runtime tracking.

- Enhanced transparency for contractors, remote workers, and fuel suppliers.

- List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance, MultiTank | Location | - | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, TPMS, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Visiting the Geofences, Log, Custom Events |

A sample set of reports and options specific to monitoring in various industries. This set may vary from case to case

| Fuel monitoring | Movement & GPS monitoring | Genset utilization & overloads | CAN Bus readings | Auxiliary equipment | Geofences & routes | CO2 emissions (standstills) | Remote disabling | RFID/iButton (authorization) | |

|---|---|---|---|---|---|---|---|---|---|

| Data centers | + | + | + | + | |||||

| Telecom | + | + | + | + | |||||

| Fuel stations | + | + | + | ||||||

| Banks | + | + | + | + | |||||

| Hospitals | + | + | + | + | + | ||||

| Construction | + | + | + | + | + | + | |||

| Leasing | + | + | + | + | + | + | + | ||

| Where does the data come from | LLS sensors, CAN-bus, VH dashboard, aux-equipment | Terminal | Terminal (RPM, temperature sensors, aux-equipment), CAN-bus, MODBUS | CAN-bus | Terminal, aux-equipment | Terminal | Terminal, CAN-bus | Terminal & 3rd-party equipment (relays) | Terminal & 3rd-pary equipment, ICON |

Why Omnicomm

High-precision fuel-level sensors ensure reliable monitoring even in harsh conditions.

Industrial-grade telematics designed for vibration, dust, heat, and high-load environments.

Flexible integration via analog, RS-485, CANBus, Modbus, and digital I/O.

Real-time cloud monitoring with detailed anomaly detection and event history.

Scalable architecture – suitable for single gensets or large distributed fleets.

Proven reliability in telecom, mining, and energy operations globally.