Agriculture

In agricultural settings (farms, plantations, seasonal work, remote fields), reliable monitoring of fuel, machinery usage, and resource consumption is critical. Fuel-powered equipment — tractors, combine harvesters, irrigation pumps, fuel bowsers, sprayers, generators — often work in remote, distributed locations. Monitoring fuel levels, consumption, dispensing, and machine operation helps optimize efficiency, reduce fuel losses and theft, schedule maintenance, and manage resources transparently.

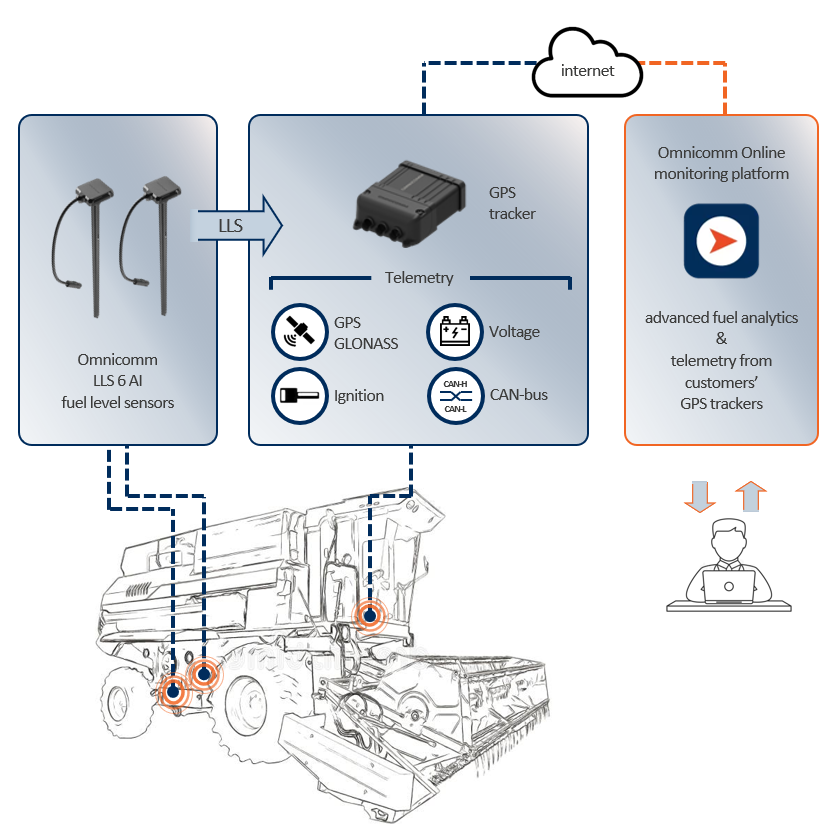

Omnicomm offers tailored monitoring solutions for agricultural machinery, utilizing LLS sensors to accurately measure fuel levels alongside comprehensive monitoring of basic telemetry and various auxiliary equipment. Our system integrates data from CAN bus interfaces, providing real-time insights that enhance operational efficiency, optimize fuel consumption, and support effective management of agricultural equipment in diverse field conditions.

Using Omnicomm sensors and telemetry combined with remote monitoring, farms and agri-enterprises can maintain control over fuel supply, equipment use, and operational costs even in distributed or remote conditions.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 6 AI | 2 |

| GPS-tracker Profi 3.0 / Optim 3.0 / Teltonika FMC125 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| CAN-bus reader(s) | 1 |

Key Advantages and Strengths:

- Accurate Fuel Inventory & Issuance Control

- Machine Utilization, Logistics and Operational Transparency

- Cost Savings, Loss Prevention & Efficiency

- Flexibility and Scalability

Recommended Reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining, Fuel Balance | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, TPMS, Operation for the Period, Load for the Period | Violations, Events, SafeDrive | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Trip Report, Group Work, Group Ratings, Active Trips, Custom Events |

Why Omnicomm

Reliable fuel-level sensors (LLS series) designed to handle motion, vibrations, tilting — suitable for off-road, rough-terrain agricultural machinery.

Modular telemetry and monitoring system — works across different equipment types (vehicles, stationary units, bowsers), allowing flexible deployment.

Transparent fuel accounting and dispensing logging — ensures accountability for all fuel issued or consumed, reducing possibility of unaccounted losses, theft, or misuse.

Scalable architecture — from a single tractor to a large fleet across multiple farms or fields. Data aggregation and reporting make management and decision-making easier.

Operational insights and efficiency improvements — by combining fuel consumption, location, runtime and usage data, managers can derive metrics (fuel per hectare, fuel per hour, idle vs work time), identify inefficiencies, and optimize workflows.