Mining & Construction

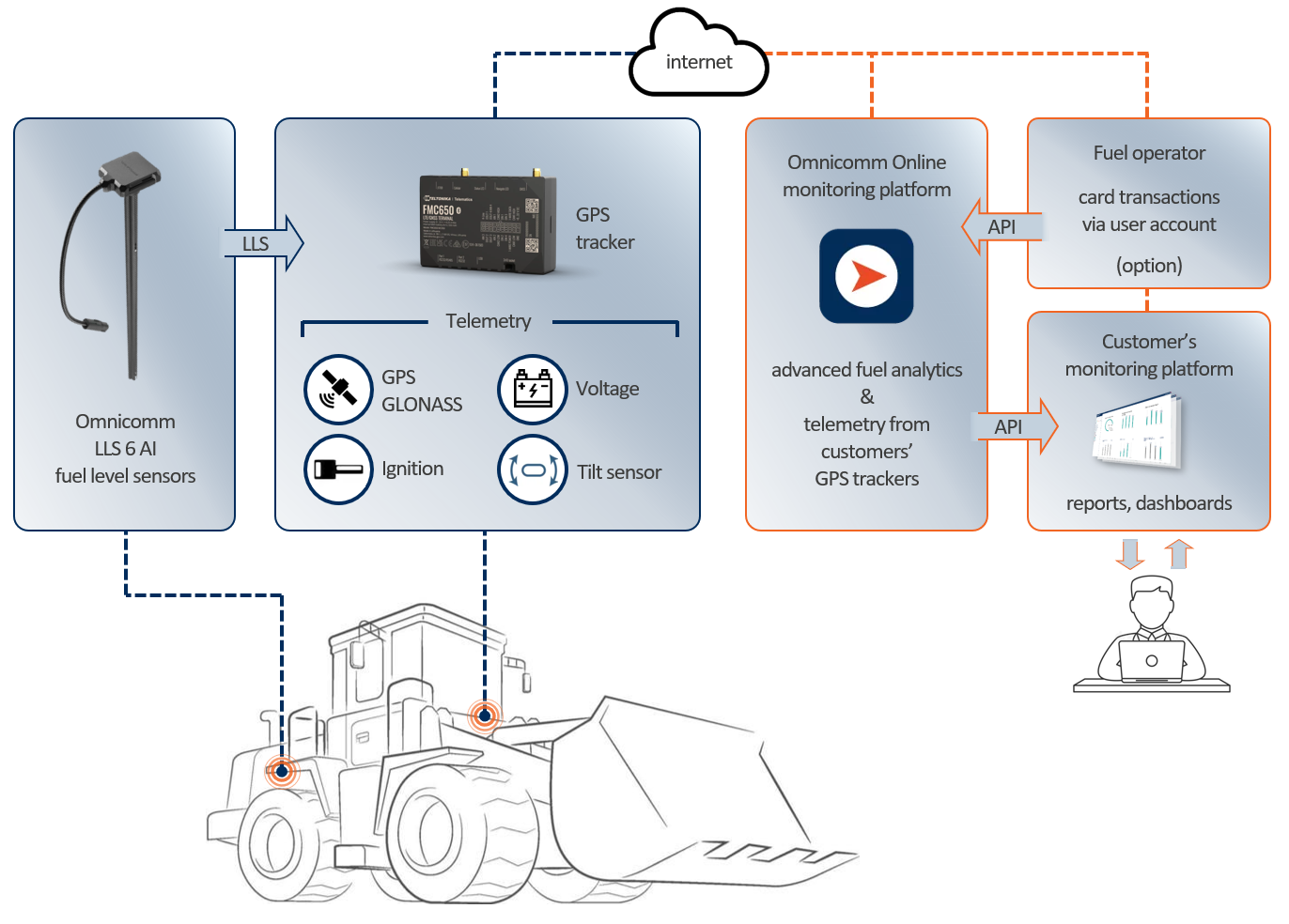

This configuration covers heavy‑duty equipment commonly used in mining, construction, road works, earth‑moving, or quarries: excavators, bulldozers, dump trucks, loaders, cranes, generators, stationary equipment, etc. The goal is to monitor fuel consumption, equipment operation (hours, load, idle time), location / geofencing, and fuel supply/dispensing for improved efficiency, safety and cost control.

Typical Equipment Configuration

| Unit | Qty |

|---|---|

| Fuel Level Sensor LLS 6 AI - 700mm | 1 |

| GPS-tracker Profi 3.0 / Teltonika FMC650 / Xirgo LX45 / … | 1 |

| Omnicomm Online service license | 1 |

| Options | |

| Omnicomm ICON display | 1 |

| Wireless CAN-bus reader(s) | 1 |

| Axle weight sensor | 1 |

| Manipulator tilt sensor | 1 |

Key Advantages and Strengths:

- The LLS sensors (LLS 4 or LLS 5) are purpose-built for heavy machinery, with high environmental resistance: robust casing, sealed connections, dust/water resistance, and ability to operate under heavy vibrations, jolts, dirt — common in mining/construction sites.

- High measurement accuracy ensures real fuel level readings even when fuel sloshing or varying fuel densities, which helps avoid under- or overestimation due to harsh operating conditions or terrain changes.

- Continuous, real‑time monitoring of fuel level enables immediate detection of refuels, draining, leaks, or unauthorized fuel removal — crucial in remote job‑site operations where manual fuel checks are impractical.

List of useful reports in Omnicomm Online

| Fuel | Cartographic | Movement | Statistics | Operation | Events and Violations | Analytical | Other |

|---|---|---|---|---|---|---|---|

| Fuel Volume, Refueling and Draining | Track, Location | Standstills, Speed, Movement | Statistics, Summary Report, Shifts Report | RPM, Voltage, Auxiliary Equipment Operation, Engine Load, Operation for the Period, Load for the Period | - | Executive’s Desktop | Current State, Visiting the Geofences, Log, Drivers Registration, Job Status, Group Work, Group Ratings, Custom Events |

* [3PP] – 3rd party product

Why Omnicomm

Omnicomm’s solutions are tailored for heavy‑duty, harsh‑environment industries: sensors with high accuracy and durability, trackers rated for vibration/dust/weather, flexible integration, and a unified cloud platform enabling fleet‑wide control. This translates into fuel cost savings, improved equipment efficiency, reduced losses, and reliable data for management and audits.

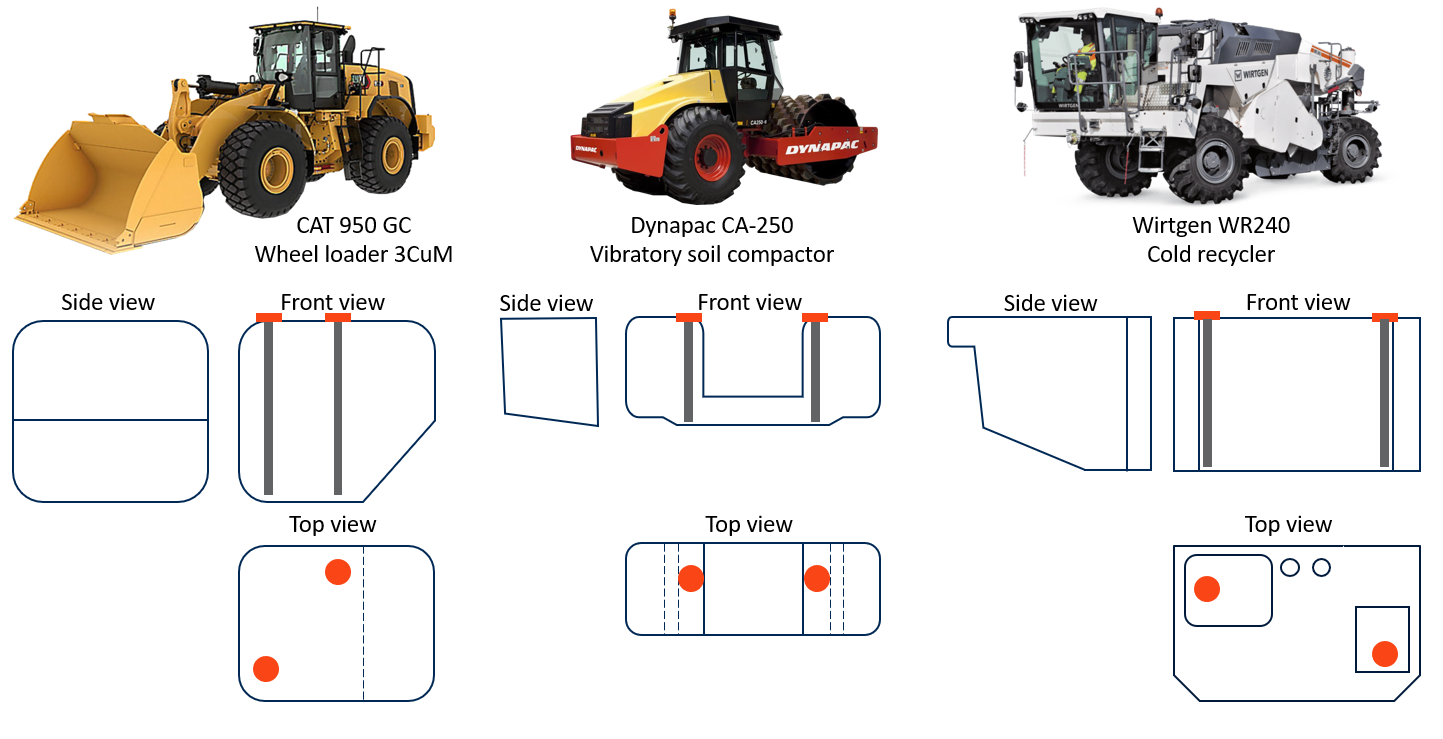

Various Shapes Of Fuel Tanks

In mining and construction equipment, fuel tanks often have complex and varied shapes — cylindrical drums, rectangular modules, baffle‑reinforced compartments, and other irregular designs. These shapes critically affect how well a fuel‑level sensor can measure volume. Proper placement, calibration, and installation are essential to ensure reliable, accurate readings.

Why Tank Shape Matters

- Heavy-duty machinery and construction/mining equipment often have non-standard or irregular-shaped fuel tanks (cylindrical, curved, non-rectangular, with internal reinforcements, baffles, ribs, sloped bottoms, etc.). The shape affects how accurately a fuel-level sensor measures fuel volume when the tank is partly filled, tilted, or under load.

- Irregular geometry, internal obstacles (ribs, stiffeners, internal structures), sloping bottoms, or non-uniform cross-sections may cause inaccurate readings, especially if a sensor is placed suboptimally — e.g. off-center, near a wall or rib, or where dead zones/residual pockets exist.

- For mobile heavy equipment, tilt, slope, or movement (uneven terrain) aggravate the problem: if sensor installation doesn’t compensate for such geometry/tilt, readings may fluctuate significantly, reducing reliability of fuel data — critical for monitoring in mining/construction contexts.

Therefore, correct selection and installation of fuel-level sensors must take tank shape fully into account.