Tank Calibration

Tank calibration is necessary to establish the correspondence between the digital code output by the Omnicomm LLS Neo sensor and the actual fuel volume in a specific fuel tank.

Tank calibration involves filling the tank with fuel — from empty to full — in defined increments, while recording the Omnicomm LLS Neo sensor readings in a calibration table.

Calibration of the tank can also be performed using the drain method.

Calibration of a tank equipped with multiple Omnicomm LLS Neo sensors is performed in the same way as calibration with a single sensor. Before starting calibration, add the required number of sensors and assign their network addresses. Calibration is carried out for all sensors simultaneously. Multiple sensors are connected to the PC using a KTZ splitter.

Calibration must be performed using the same fuel that was used for the “Empty/Full” calibration.

If calibration is performed using a different fuel, disable Auto Adjustment before starting the calibration. After completing calibration, enable Auto Adjustment and click “Write to Device.”

Calibration of a tank with one Omnicomm LLS Neo sensor:

1. Empty the fuel tank.

2. Connect the sensor to the PC according to the diagram in the section Configuration.

3. Launch the Omnicomm Configurator software. Select “Calibration.”

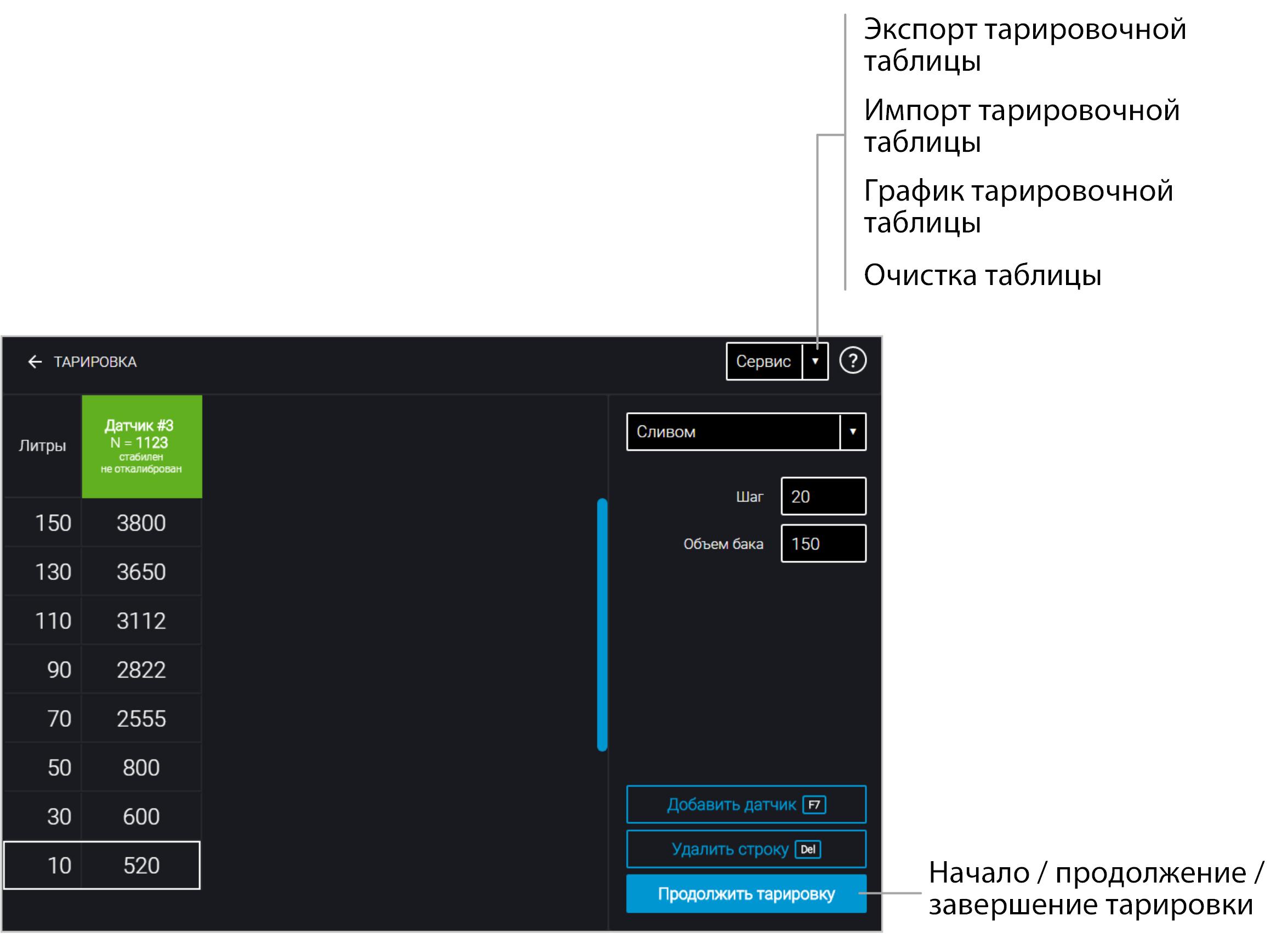

Omnicomm Configurator (PC):

If the sensor readings column is not displayed, click “Add Sensor.” Select the sensor type and specify the network address assigned during configuration.

4. Set the filling step (in liters).

If the tank geometry is non-linear and/or has expansions or constrictions, for higher accuracy it is recommended to perform calibration with a smaller filling step in those areas, using smaller measurement containers (with higher resolution).

5. Click “Start/Continue Calibration.”

6. Pour a volume of fuel equal to the filling step. Wait for the fuel level to stabilize.

Refueling should be carried out using a calibrated measuring container or under the control of a certified liquid flow meter with the specified step. The measuring container must have metrological verification.

7. Click “Add Row.”

The “Liters” column will display the fuel volume corresponding to the set filling step.

The “Sensor” column will display the value corresponding to that fuel volume.

8. Click “Add Row” again.

9. Repeat steps 6, 7, and 8 for the required number of control points. The recommended minimum number of control points is 20. To export a calibration table for fuel volumes exceeding 65,534 liters, use the F2 key.

10. Click “Finish Calibration.”

11. Save the calibration table as a .ctb calibration file, an Omnicomm Online (.xml) file, or directly to the Terminal or Indicator by clicking “Export.”

When exporting the calibration table as an Omnicomm Online (.xml) file, the “Export” window will open. Specify the Omnicomm LLS sensor number for display in Omnicomm Online.