Installation and Connection

When installing fuel level sensors on plastic tanks, it is necessary to ensure a reliable electrical connection between the sensor body wire and the vehicle frame. Failure to do so may cause the sensor to malfunction due to static electricity.

Installation on cylindrical tanks with a diameter of 420–710 mm should be performed according to the section Recommendations for Installing Sensors on Cylindrical Tanks.

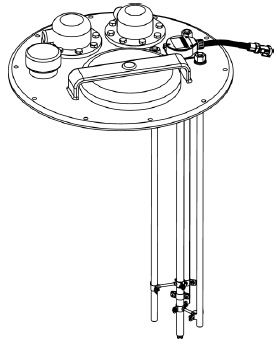

1. Place the gasket included in the sensor kit onto the measuring section of the Omnicomm LLS sensor at the mounting point.

2. Install the Omnicomm LLS sensor in the tank and secure it:

* For rivet mounting, use a rivet gun. * For bolt mounting, first place a seal (on one bolt), a washer, and a lock washer. * For mounting on plastic tanks with wall thickness over 3 mm, use the self-tapping screws and seal (for one screw) included in the kit.

3. Connect the Omnicomm LLS sensor to the external device:

4. Connect the fuse holder to the sensor power wire (brown wire) close to the vehicle power circuit.

5. Install the fuse in the fuse holder.

6. If necessary, seal the bolt (or self-tapping screw) and the connector.

Multiple Omnicomm LLS sensors are connected in parallel via the RS-485 interface.

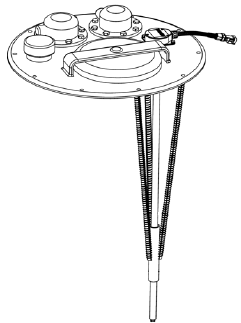

For installation in vehicle fuel tanks using sensors with a measuring section longer than 1.5 m, it is recommended to reinforce the measuring section using steel studs and clamps or steel rods as appropriate: