Preparation

Tank Preparation

1. Choose the installation location for the Omnicomm LLS sensor considering the following requirements:

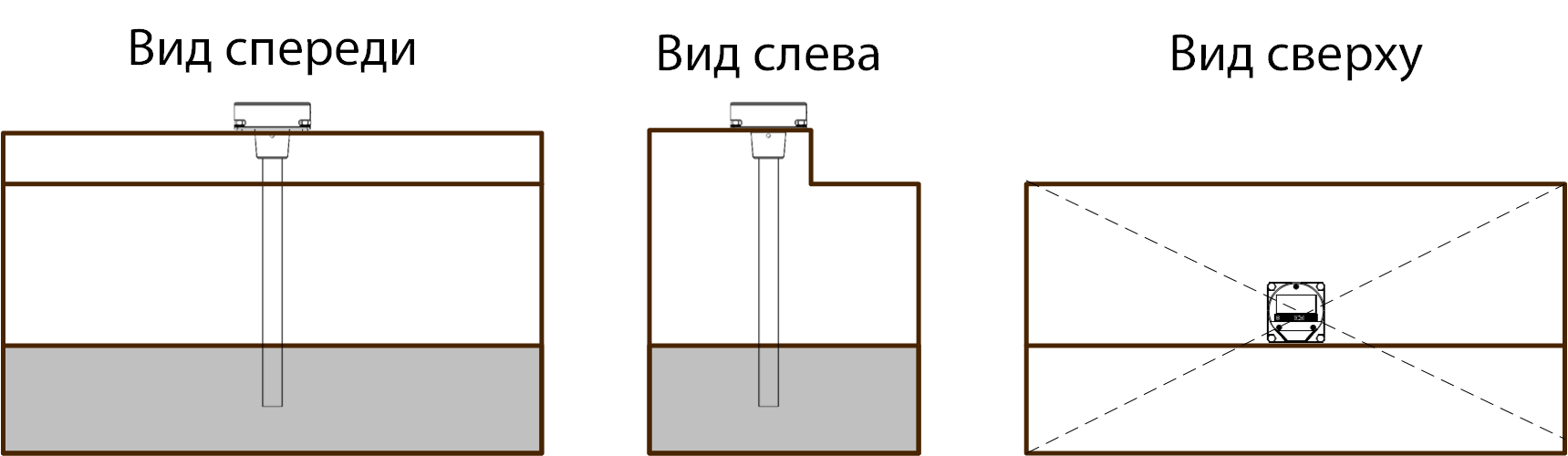

- The installation point should be as close as possible to the geometric center of the tank and be the deepest part of the tank:

- The installed sensor must not touch stiffeners or any additional equipment inside the tank.

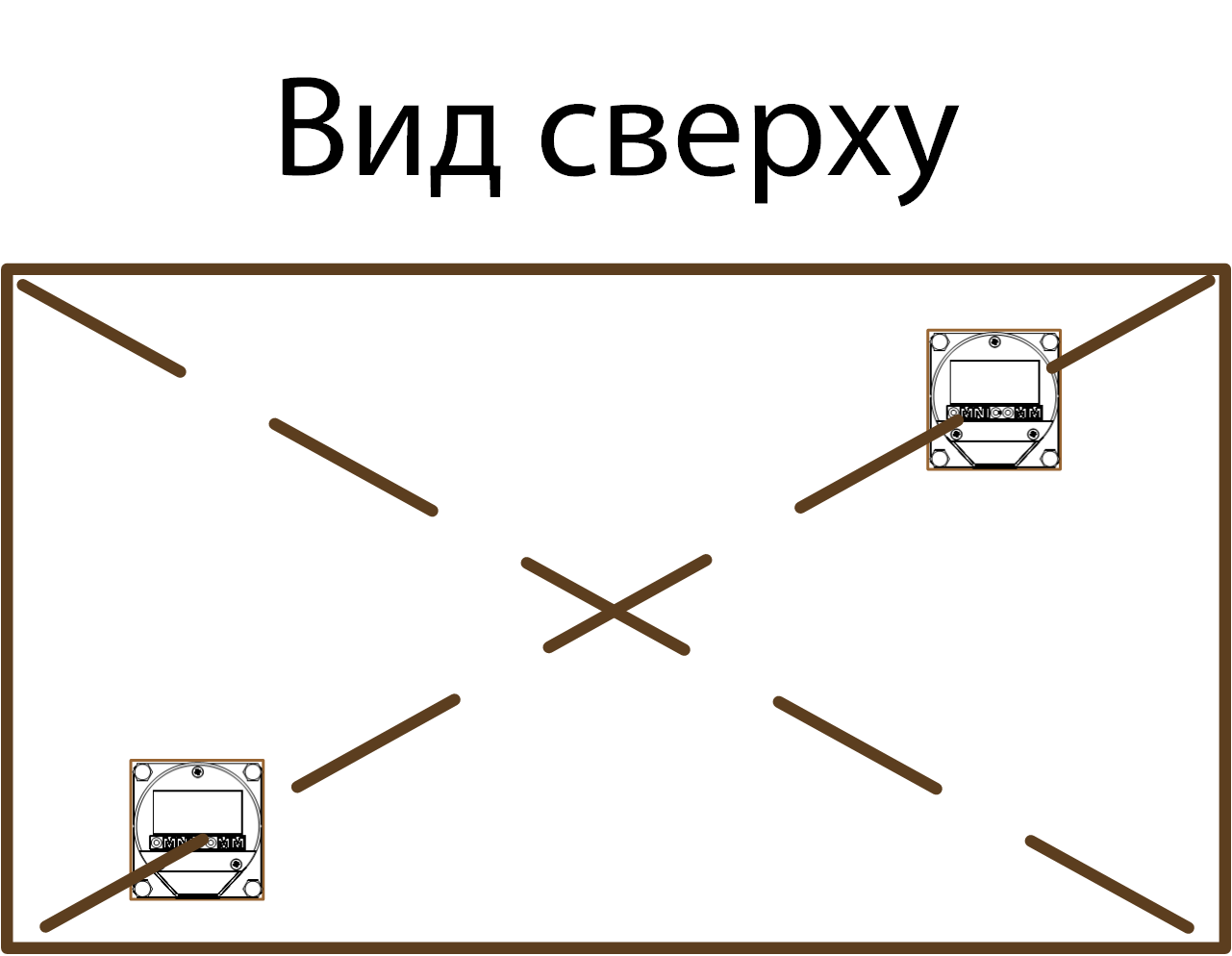

- Installing two sensors in one fuel tank significantly reduces the influence of the vehicle’s tilt angle on fuel level readings:

2. For safety reasons, perform tank vaporization.

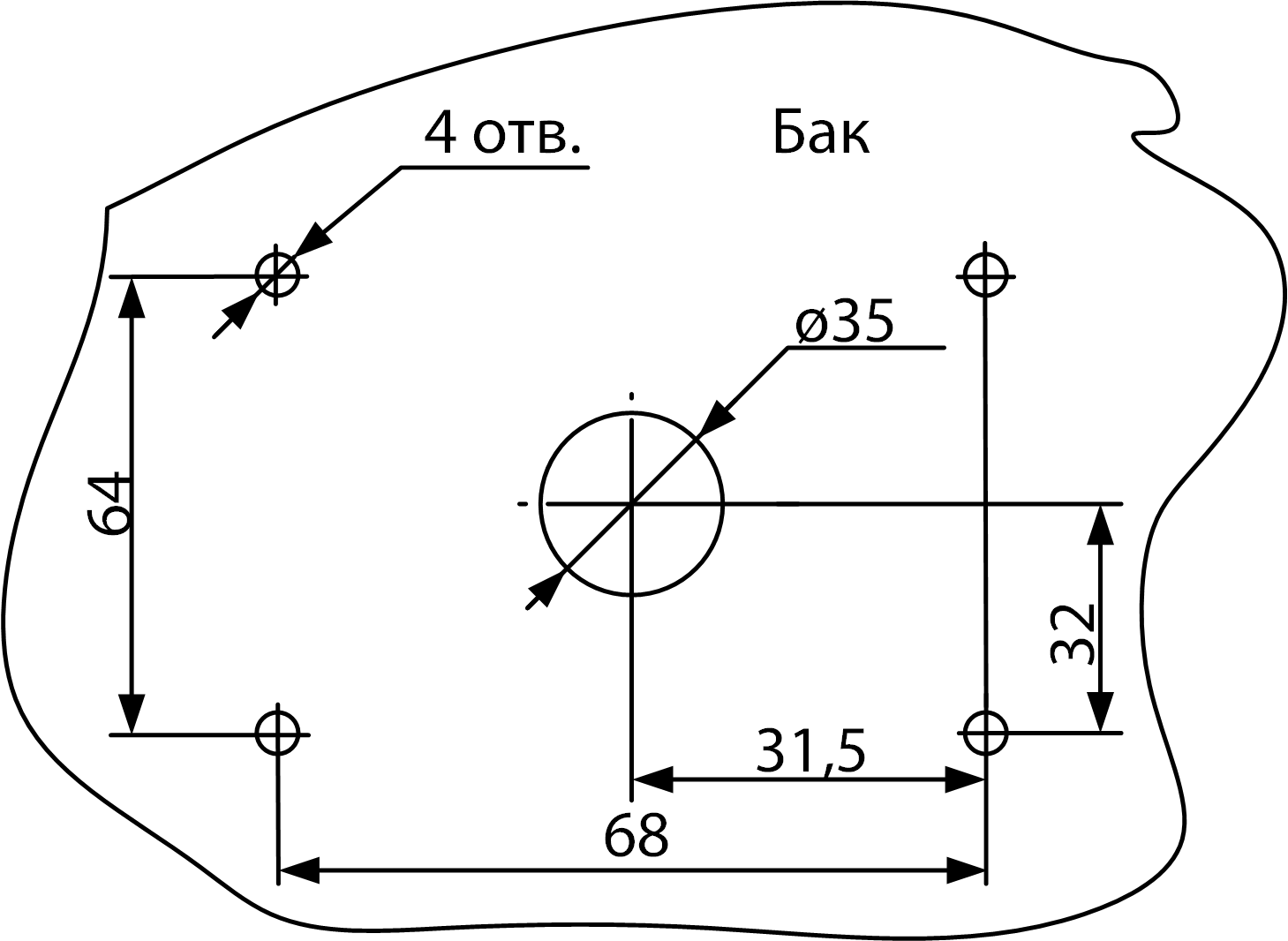

3. Drill a central hole using a bi-metal hole saw, ø35 mm.

4. Drill four mounting holes according to the diagram:

The diameter of the mounting holes depends on the tank material:

- ø 4 mm for a metal tank with wall thickness over 3 mm (tap M5 thread)

- ø 7 mm for plastic or metal tanks with wall thickness up to 3 mm (for rivets)

- ø 4 mm for plastic tanks over 3 mm thick