Login

You are currently not logged in! Enter your authentication credentials below to log in. You need to have cookies enabled to log in.

Preparation

Tank Preparation

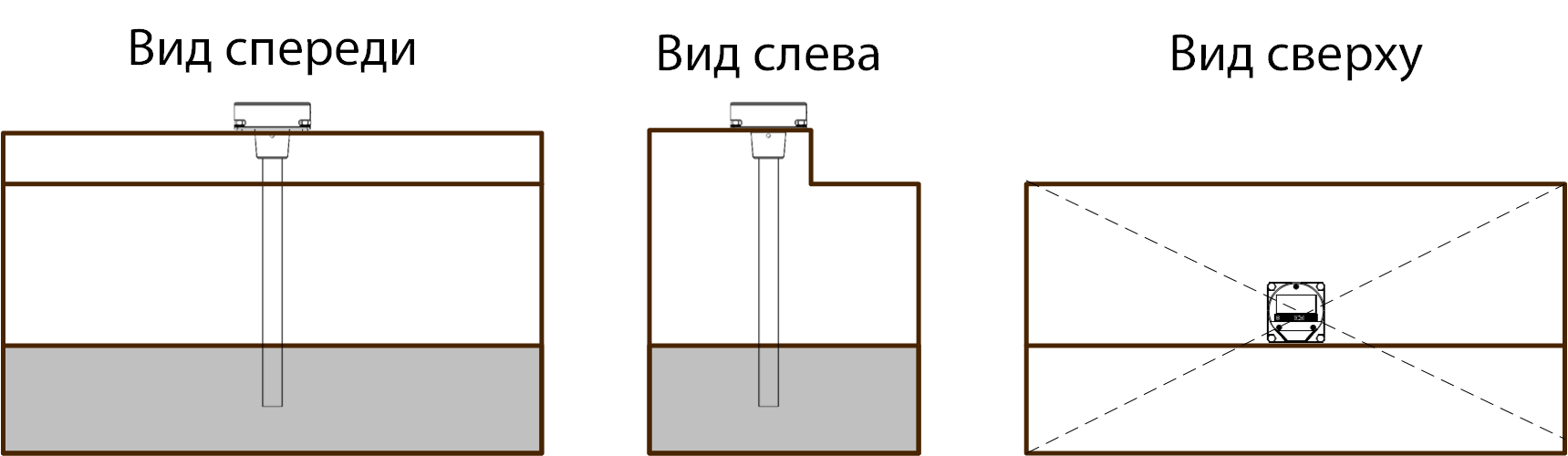

1. Choose the installation location for the Omnicomm LLS sensor considering the following requirements:

- The installation point should be as close as possible to the geometric center of the tank and be the deepest part of the tank:

- The installed sensor must not touch stiffeners or any additional equipment inside the tank.

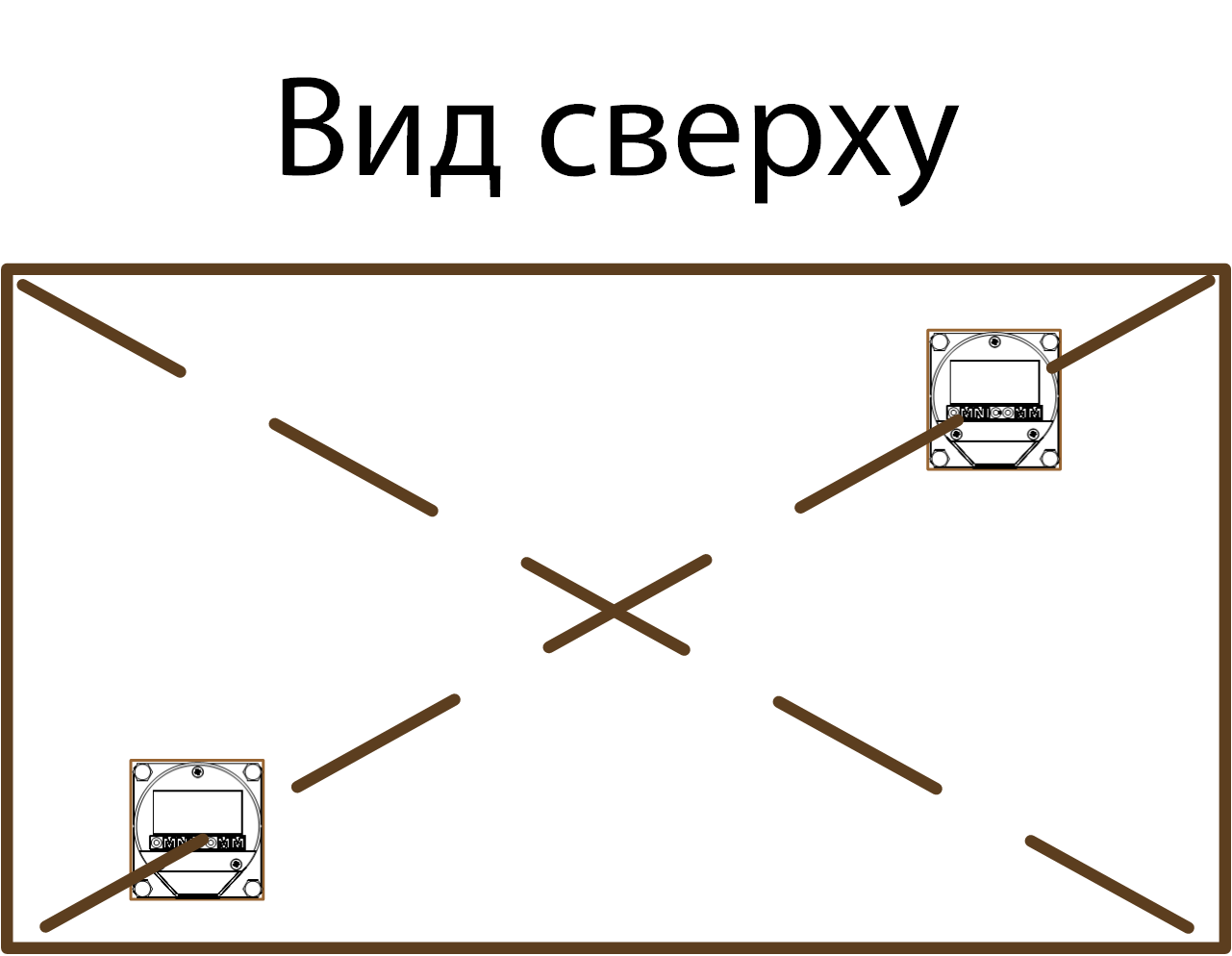

- Installing two sensors in one fuel tank significantly reduces the influence of the vehicle’s tilt angle on fuel level readings:

2. For safety reasons, perform tank vaporization.

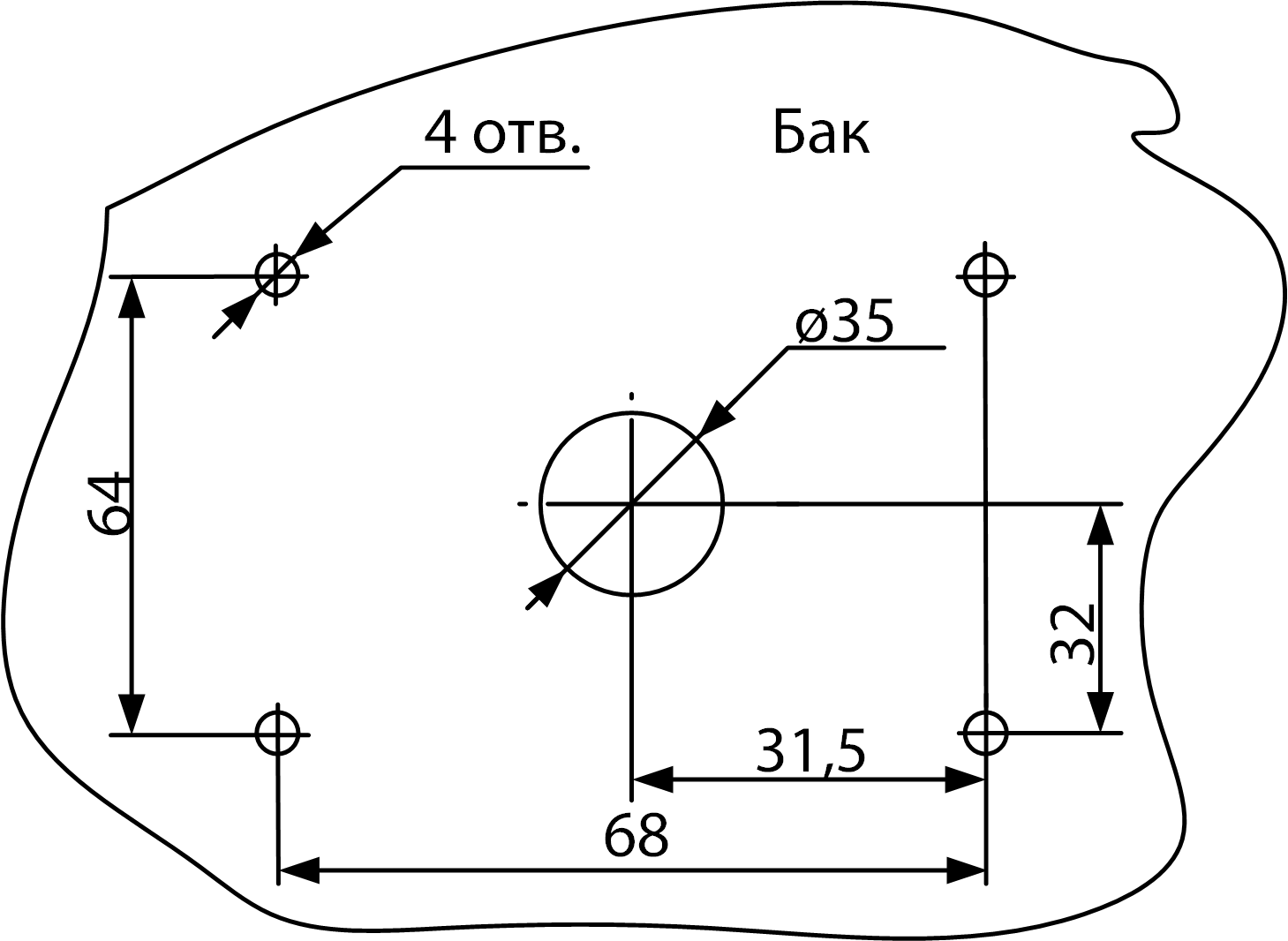

3. Drill a central hole using a bi-metal hole saw, ø35 mm.

4. Drill four mounting holes according to the diagram:

The diameter of the mounting holes depends on the tank material:

- ø 4 mm for a metal tank with wall thickness over 3 mm (tap M5 thread)

- ø 7 mm for plastic or metal tanks with wall thickness up to 3 mm (for rivets)

- ø 4 mm for plastic tanks over 3 mm thick

Sensor Preparation

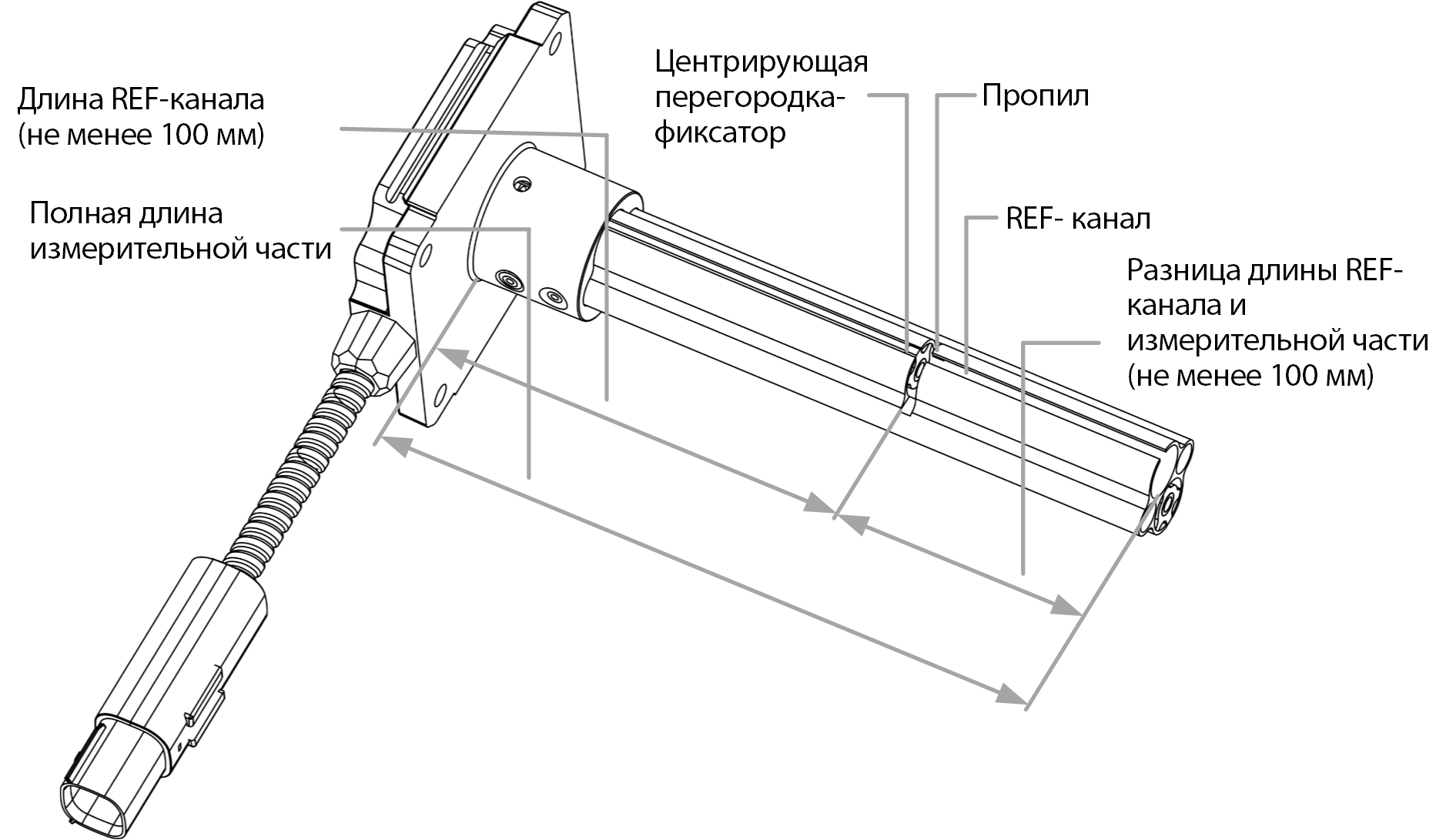

1. Cut the measuring section of the sensor according to the following recommendations:

- The length of the measuring section should be 20 mm shorter than the depth of the tank.

- The REF channel must be at least 100 mm shorter than the measuring section of the sensor. If the difference is less than 100 mm, trim the REF channel according to the diagram:

2. Install the centering partition inside the measuring section of the sensor at a depth of 1 cm.

REF Channel Trimming (only if the length difference between the REF channel and the measuring section is less than 100 mm):

1. Install the centering partition inside the REF channel close to the cutting point.

2. Make a cut with a cutting wheel (diameter not exceeding 125 mm).

3. Remove the cut-off segment of the REF channel rod.

The REF channel rod is shorter than the main measuring rod and is located on the right when viewing the sensor body from the connector side.